Abstract

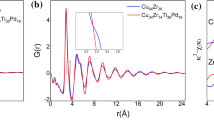

The formation of bulk metallic glasses (BMGs) was systematically investigated in the ternary Ti-Cu-Ni and quaternary Ti-Zr-Cu-Ni systems. Over a relatively wide composition range (50 to 57 at. pct Ti, 34 to 44 at. pct Cu, and 6 to 10 at. pct Ni) in the ternary Ti-Cu-Ni system, new Ti-based BMGs with a critical diameter of 1 mm have been discovered in the triangular region enclosed by the three intermetallic compounds TiNi, TiCu, and Ti2Cu. Partial substitution of Zr for Ti improved the glass-forming ability (GFA), and the BMGs of 3 mm in diameter were obtained in the composition range of 51 to 53 at. pct (Ti + Zr), 38 to 41 at. pct Cu, and 8 to 10 at. pct Ni. The enhanced GFA compared with the ternary Ti-Ni-Cu system was attributed to the effects of Zr on stabilizing the undercooled liquid. These Ti-based BMGs had compressive fracture strength higher than 2 GPa. Among them, the Ti50Cu43Ni7 glass exhibited a reproducible plastic strain larger than 5 pct.

Similar content being viewed by others

References

K.B. Kim, J. Das, X.D. Wang, X. Zhang, J. Eckert, S. Yi: Phil. Mag. Lett., 2006, vol. 86, pp. 479–86

G. Wang, Y.H. Liu, P. Yu, D.Q. Zhao, M.X. Pan, and W.H. Wang: Appl. Phys. Lett., 2006, vol. 89, pp. 251909-1–251909-3

T. Ohkubo, D. Nagahama, T. Mukai, K. Hono: J. Mater. Res., 2007, vol. 22, pp. 1406–13

X.F. Zhang, K.B. Kim, J. Das, S. Yi, J. Eckert: J. Mater. Res., 2007, vol. 22, pp. 2223–29

J. Shen, Y.J. Huang, J.F. Sun: J. Mater. Res., 2007, vol. 22, pp. 3067–74

E.S. Park, H.J. Chang, J.Y. Lee, D.H. Kim: J. Mater. Res., 2007, vol. 22, pp. 3440–47

H. Ma, L.L. Shi, J. Xu, Y. Li, and E. Ma: Appl. Phys. Lett., 2005, vol. 87, pp. 181915-1–181915-3

Q. Zheng, J. Xu, and E. Ma: J. Appl. Phys., 2007, vol. 102, pp. 113519-1–113519-5

D.H. Xu, G. Duan, and W.L. Johnson: Phys. Rev. Lett., 2004, vol. 92, pp. 245504-1–245504-4

C.L. Dai, H. Guo, Y. Shen,Y. Li, E. Ma, J. Xu: Scripta Mater., 2006, vol. 54, pp. 1403–08

P. Jia, H. Guo, Y. Li, J. Xu, E. Ma: Scripta Mater., 2006, vol. 54, pp. 2165–68

Y. Shen, E. Ma, J. Xu: J. Mater. Sci. Technol., 2008, vol. 24, pp. 149–52

Z.P. Lu, C.T. Liu, J.R. Thompson, and W.D. Porter: Phys. Rev. Lett., 2004, vol. 92, pp. 245503-1–245503-4

V. Ponnambalam, S.J. Poon, G.J. Shiflet: J. Mater. Res., 2004, vol. 19, pp. 1320–23

T. Zhang, A. Inoue: Mater. Trans. JIM, 1999, vol. 40, pp. 301–06

T. Zhang, A. Inoue: Mater. Sci. Eng. A, 2001, vols. 304–306, pp. 771–74

C.L. Ma, S. Ishihara, H. Soejima, N. Nishiyama, A. Inoue: Mater. Trans., 2004, vol. 45, pp. 1802–06

C.L. Ma, H. Soejima, S. Ishihara, K. Amiya, N. Nishiyama, A. Inoue: Mater. Trans., 2004, vol. 45, pp. 3223–27

H. Men, S.J. Pang, A. Inoue, T. Zhang: Mater. Trans., 2005, vol. 46, pp. 2218–20

Y.J. Huang, J. Shen, J.F. Sun, X.B. Yu: J. Alloys Compd., 2007, vol. 427, pp. 171–75

F.Q. Guo, H.J. Wang, S.J. Poon, and G.J. Shiflet: Appl. Phys. Lett., 2005, vol. 86, pp. 091907-1–091907-3

J.M. Park, Y.C. Kim, W.T. Kim, D.H. Kim: Mater. Trans., 2004, vol. 45, pp. 595–98

G. Duan, K.D. Blauwe, M.L. Lind, J.P. Schramm, W.L. Johnson: Scripta Mater., 2008, vol. 58, pp. 465–68

T. Zhang, A. Inoue: Mater. Trans. JIM, 1998, vol. 39, pp. 1001–06

Y.C. Kim, S. Yi, W.T. Kim, D.H. Kim: Mater. Sci. Forum, 2001, vols. 360–362, pp. 67–72

D. Wang, Y. Li, B.B. Sun, M.L. Sui, K. Lu, E. Ma: Appl. Phys. Lett., 2004, vol. 84, pp. 4029–31

H. Ma, Q. Zheng, J. Xu, Y. Li, E. Ma: J. Mater. Res., 2005, vol. 20, pp. 2252–55

H. Ma, L.L. Shi, J. Xu, Y. Li, E. Ma: J. Mater. Res., 2006, vol. 21, pp. 2204–14

R.D. Conner, W.L. Johnson: Scripta Mater., 2006, vol. 55, pp. 645–48

Y.H. Liu, G. Wang, R.J. Wang, D.Q. Zhao, M.X. Pan, W.H. Wang: Science, 2007, vol. 315, pp. 1385–88

G. Duan, K.D. Blauwe, M.L. Lind, J.P. Schramm, W.L. Johnson: Scripta Mater., 2008, vol. 58, pp. 159–62

Y.L. Wang, E. Ma, J. Xu: Phil. Mag. Lett., 2008, vol. 88, pp. 319–25

K.M. Knowles, D.A. Smith: Acta Metall., 1981, vol. 29, pp. 101–10

K. Gschneidner, A. Russell, A. Pecharsky, J. Morris, Z.H. Zhang, T. Lograsso, D. Hsu, C.H. Chesterlo, Y.Y. Ye, A. Slager, D. Kesse: Nat. Mater., 2003, vol. 2, pp. 587–91

J. Morris, Y. Ye, M. Kremar, C.L. Fu: Mater. Res. Soc. Symp. Proc., 2007, vol. 980, pp. 1106–10

Y. Li, S.J. Poon, G.J. Shiflet, J. Xu, D.H. Kim, J.F. Löffler: MRS Bull., 2007, vol. 32, pp. 624–28

Q. Zheng, H. Ma, E. Ma, J. Xu: Scripta Mater., 2006, vol. 55, pp. 541–44

L. Zhang, M.J. Zhuo, J. Xu: J. Mater. Res., 2008, vol. 23, pp. 688–99

L. Zhang, E. Ma, J. Xu: Intermetallics, 2008, vol. 16, pp. 584–86

S.P. Alisova, N.V. Volynskaya, P.B. Budbery, and A.V. Kobylkin: in Handbook of Ternary Alloy Phase Diagrams, P. Villars, A. Prince, and H. Okamoto, eds., ASM INTERNATIONAL, Materials Park, OH, 1995, vol. 8, pp. 9846–61

G. He, J. Eckert, M. Hagiwara: Mater. Lett., 2006, vol. 60, pp. 656–61

W.F. Wu, Y. Li, C.A. Schuh: Phil. Mag., 2008, vol. 88, pp. 71–89

K. Mondal, G. Kumar, T. Ohkubo, K. Oishi, T. Mukai, K. Hono: Phil. Mag. Lett., 2007, vol. 87, pp. 625–35

J.L. Murray: in Binary Alloy Phase Diagram, 2nd ed., T.B. Massalski, H. Okamoto, P.R. Subramanian, and L. Kacprzak, eds., ASM INTERNATIONAL, 1990, vol. 2, pp. 1494–96

F.R. De Boer, R. Boom, W.C.M. Mattens, A.R. Miedema, and A.K. Niessen: Cohesion in Metals, North-Holland, Amsterdam, 1988

H.W. Sheng, W.K. Luo, F.M. Alamgir, J.M. Bai, E. Ma: Nature, 2006, vol. 439, pp. 419–25

W.J. Meng, B. Fultz, E. Ma, W.L. Johnson: Appl. Phys. Lett., 1987, vol. 51, p. 661

Y.Y. Zhao, E. Ma, J. Xu: Scripta Mater., 2008, vol. 58, pp. 496–99

X.J. Gu, S.J. Poon, G.J. Shiflet, M. Widom: Acta Mater., 2008, vol. 56, pp. 88–94

H.J. Wang, X.J. Gu, S.J. Poon, and G.J. Shiflet: Phys. Rev. B., 2008, vol. 77, pp. 014204-1–014204-8

R. Ferro and A. Saccone: in Structure of Intermetallc Compounds and Phases in Physical Metallurgy, 4th revised and enhanced ed., R.W. Cahn and P. Haasen, eds., Elsevier Science B.V., Amsterdam, The Netherlands, 1996, p. 205

Y.K. Xu, H. Ma, J. Xu, E. Ma: Acta Mater., 2005, vol. 53, pp. 1857–66

Acknowledgments

The authors gratefully acknowledge the stimulating discussion with Professors E. Ma, Y. Li, and C. Suryanarayana. This research was supported by the National Natural Science Foundation of China under Contract No. 50871112 and the National Basic Research Program of China (973 Program) under Contract No. 2007CB613906.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 5, 2008.

Rights and permissions

About this article

Cite this article

Wang, YL., Xu, J. Ti (Zr)-Cu-Ni Bulk Metallic Glasses with Optimal Glass-Forming Ability and Their Compressive Properties. Metall Mater Trans A 39, 2990–2997 (2008). https://doi.org/10.1007/s11661-008-9647-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9647-6