Abstract

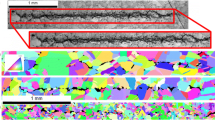

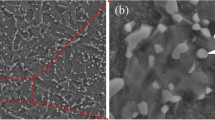

Microstructural and crystallographic aspects of high-velocity forming or “rapid” forming of rolled sheets of pure copper have been investigated in this work. Significant changes in crystallographic orientation and microstructure were observed when thin (0.5 mm) metal sheets of annealed copper were subjected to high strain rate deformation in a conventional shock tube at a very low impulse magnitude (∼0.2 N s), which is inconceivable in conventional metal forming. Shock-loaded samples show characteristic texture evolution with a high brass {110}〈112〉 component. A significant change in grain orientation spread was observed with increasing amount of effective strain without any drastic change in grain size. The texture after deformation was found to be strain-dependent. The path of texture evolution is dependent on the initial texture. Misorientation was limited to less than 5°. Deformation bands and deformation twins were observed. There was a decrease in twin [Σ3 coincidence site lattice (CSL)] boundary number fraction with increasing strain due to the change in twin boundary character to high-angle random boundary (HARB) as a result of dislocation pile up. The study shows the probability of a high-velocity shock wave forming pure Cu.

Similar content being viewed by others

References

M. Stoffel: Limit states of elastic–viscoplastic plate deformations caused by repeated shock wave-loadings. Part 1: Experimental observation. Mech. Res. Commun. 33(6), 771 (2006).

M. Stoffel: Limit states of elastic–viscoplastic plate deformations caused by repeated shock wave-loadings. Part 2: Theoretical modelling. Mech. Res. Commun. 33(6), 775 (2006).

R. Shabadi, S. Suwas, S. Kumar, H. Roven, and E. Dwarkadasa: Texture and formability studies on AA7020 Al alloy sheets. Mater. Sci. Eng., A 558, 439 (2012).

J.E. Cohen, A. Nelson, and R.J. De Angelis: Some Observations On Shock-Loaded Copper (DTIC Document, Northwestern University, Evanston, 1965).

A.G. Dhere, H-J. Kestenbach, and M.A. Meyers: Correlation between texture and substructure of conventionally and shock-wave-deformed aluminum. Mater. Sci. Eng. 54(1), 113 (1982).

G.T. Higgins: The structure and annealing behavior of shock-loaded, cube-oriented copper. Metall. Trans. 2(5), 1277 (1971).

L.F. Trueb: Electron-microscope study of thermal recovery processes in explosion-shocked nickel. J. Appl. Phys. 40(7), 2976 (1969).

M. Rose and T. Berger: Shock deformation of polycrystalline aluminium. Philos. Mag. 17(150), 1121 (1968).

N. Ray, G. Jagadeesh, and S. Suwas: Response of shock wave deformation in AA5086 aluminum alloy. Mater. Sci. Eng., A 622, 219 (2015).

S. Suwas, A. Singh, K.N. Rao, and T. Singh: Effect of modes of rolling on evolution of the texture in pure copper and some copper-base alloys: Part I: Rolling texture. Z. Metallkd. 93(9), 918 (2002).

S. Suwas and A. Singh: Role of strain path change in texture development. Mater. Sci. Eng., A 356(1), 368 (2003).

N. Gurao, S. Sethuraman, and S. Suwas: Effect of strain path change on the evolution of texture and microstructure during rolling of copper and nickel. Mater. Sci. Eng., A 528(25), 7739 (2011).

S. Vercammen, B. Blanpain, B.C. De Cooman, and P. Wollants: Cold rolling behaviour of an austenitic Fe–30Mn–3Al–3Si TWIP-steel: the importance of deformation twinning. Acta Mater. 52(7), 2005 (2004).

J.J. Sidor, R.H. Petrov, and L.A. Kestens: Microstructural and texture changes in severely deformed aluminum alloys. Mater. Charact. 62(2), 228 (2011).

S. Roy, S. Singh, S. Suwas, S. Kumar, and K. Chattopadhyay: Microstructure and texture evolution during accumulative roll bonding of aluminium alloy AA5086. Mater. Sci. Eng., A 528(29), 8469 (2011).

T. Leffers and R.K. Ray: The brass-type texture and its deviation from the copper-type texture. Prog. Mater. Sci. 54(3), 351 (2009).

X.H. An, Q.Y. Lin, S.D. Wu, and Z.F. Zhang: Mechanically driven annealing twinning induced by cyclic deformation in nanocrystalline Cu. Scr. Mater. 68(12), 988 (2013).

X.H. An, S.D. Wu, Z.F. Zhang, R.B. Figueiredo, N. Gao, and T.G. Langdon: Evolution of microstructural homogeneity in copper processed by high-pressure torsion. Scr. Mater. 63(5), 560 (2010).

X.H. An, Q.Y. Lin, G. Sha, M.X. Huang, S.P. Ringer, Y.T. Zhu, and X.Z. Liao: Microstructural evolution and phase transformation in twinning-induced plasticity steel induced by high-pressure torsion. Acta Mater. 109, 300 (2016).

M.A. Meyers: A mechanism for dislocation generation in shock-wave deformation. Scr. Metall. 12(1), 21 (1978).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bisht, A., Ray, N., Jagadeesh, G. et al. Microstructural and crystallographic response of shock-loaded pure copper. Journal of Materials Research 32, 1484–1498 (2017). https://doi.org/10.1557/jmr.2017.15

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.15