Abstract

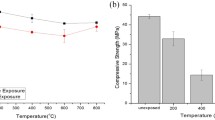

High-porosity metakaolin-based geopolymer foams (GFs) were fabricated by a gelcasting technique using hydrogen peroxide (foaming agent) in combination with Tween 80 (surfactant). Slurries processed in optimized conditions enabled to fabricate potassium based GFs with a total porosity in the range of ∼67 to ∼86 vol% (∼62 to ∼84 vol% open), thermal conductivity from ∼0.289 to ∼0.091 W/mK, and possessing a compressive strength from ∼0.3 to ∼9.4 MPa. Moreover, factors that influence the compressive strength, the porosity, the thermal conductivity, and the cell size distribution were investigated. The results showed that the cell size and size distribution can be controlled by adding different content of surfactant and foaming agent. The foamed geopolymer can also be used as adsorbents for the removal of copper and ammonium ions from wastewater. The foams, due to their low thermal conductivity, could also be used for thermal insulation. It was also possible to produce geopolymer formulations that could be printed using additive manufacturing technology (Direct Ink writing), which enabled to produce components with nonstochastic porosity.

Similar content being viewed by others

References

J. Davidovits: Geopolymer Chemistry & Applications, 3rd ed. (Institut Géopolymère, Saint-Quentin, 2011).

J. Davidovits: Geopolymers and geopolymeric materials. J. Therm. Anal. 35, 429 (1989).

I. Lecomte, M. Liégeois, A. Rulmont, R. Cloots, and F. Maseri: Synthesis and characterization of new inorganic polymeric composites based on kaolin or white clay and on ground-granulated blast furnace slag. J. Mater. Res. 18, 2571 (2003).

P. Palmero, A. Formia, P. Antonaci, S. Brini, and J. Tulliani: Geopolymer technology for application-oriented dense and lightened materials. Elaboration and characterization. Ceram. Int. 41, 12967 (2015).

R.M. Novais, L. Buruberri, G. Ascensão, M. Seabra, and J. Labrincha: Porous biomass fly ash-based geopolymers with tailored thermal conductivity. J. Cleaner Prod. 119, 99 (2016).

P. Hlaváček, V. Šmilauer, F. Škvára, L. Kopecký, and R. Šulc: Inorganic foams made from alkali-activated fly ash: Mechanical, chemical and physical properties. J. Eur. Ceram. Soc. 35, 703 (2015).

K. Hemra and P. Aungkavattana: Effect of cordierite addition on compressive strength and thermal stability of metakaolin based geopolymer. Adv. Powder Technol. 27(3), 1021 (2016).

M.H. Al-Majidi, A. Lampropoulos, A. Cundy, and S. Meikle: Development of geopolymer mortar under ambient temperature for in situ applications. Constr. Build. Mater. 120, 198 (2016).

Y. Ge, Y. Yuan, K. Wang, Y. He, and X. Cui: Preparation of geopolymer-based inorganic membrane for removing Ni2+ from wastewater. J. Hazard. Mater. 299, 711 (2015).

C. Bai and P. Colombo: High-porosity geopolymer membrane supports by peroxide route with the addition of egg white as surfactant. Ceram. Int. 43(2), 2267 (2017).

M. Minelli, V. Medri, E. Papa, F. Miccio, E. Landi, and F. Doghieri: Geopolymers as solid adsorbent for CO2 capture. Chem. Eng. Sci. 148, 267 (2016).

R.M. Novais, L.H. Buruberri, M.P. Seabra, and J.A. Labrincha: Novel porous fly-ash containing geopolymer monoliths for lead adsorption from wastewaters. J. Hazard. Mater. 318, 631 (2016).

T. Luukkonen, M. Sarkkinen, K. Kemppainen, J. Rämö, and U. Lassi: Metakaolin geopolymer characterization and application for ammonium removal from model solutions and landfill leachate. Appl. Clay Sci. 119, Part 2, 266 (2016).

F.J. López, S. Sugita, M. Tagaya, and T. Kobayashi: Metakaolin-based geopolymers for targeted adsorbents to heavy metal ion separation. J. Mater. Sci. Chem. Eng. 2, 16 (2014).

S. Sharma, D. Medpelli, S. Chen, and D. Seo: Calcium-modified hierarchically porous aluminosilicate geopolymer as a highly efficient regenerable catalyst for biodiesel production. RSC Adv. 5, 65454 (2015).

Y.J. Zhang, L.C. Liu, Y. Xu, and Y.C. Wang: A new alkali-activated steel slag-based cementitious material for photocatalytic degradation of organic pollutant from waste water. J. Hazard. Mater. 209, 146 (2012).

Z. Zhang, J.L. Provis, A. Reid, and H. Wang: Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem. Concr. Compos. 62, 97 (2015).

E. Papa, V. Medri, D. Kpogbemabou, V. Morinière, J. Laumonier, A. Vaccari, and S. Rossignol: Porosity and insulating properties of silica-fume based foams. Energy Build. 131, 223 (2016).

V. Ducman and L. Korat: Characterization of geopolymer fly-ash based foams obtained with the addition of Al powder or H2O2 as foaming agents. Mater. Charact. 113, 207 (2016).

G. Masi, W.D. Rickard, L. Vickers, M.C. Bignozzi, and A. Van Riessen: A comparison between different foaming methods for the synthesis of light weight geopolymers. Ceram. Int. 40, 13891 (2014).

J. Henon, A. Alzina, J. Absi, D.S. Smith, and S. Rossignol: Potassium geopolymer foams made with silica fume pore forming agent for thermal insulation. J. Porous Mater. 20, 37 (2013).

L. Verdolotti, B. Liguori, I. Capasso, A. Errico, D. Caputo, M. Lavorgna, and S. Iannace: Synergistic effect of vegetable protein and silicon addition on geopolymeric foams properties. J. Mater. Sci. 50, 2459 (2015).

E. Prud’homme, P. Michaud, E. Joussein, C. Peyratout, A. Smith, S. Arrii-Clacens, J. Clacens, and S. Rossignol: Silica fume as porogent agent in geo-materials at low temperature. J. Eur. Ceram. Soc. 30, 1641 (2010).

E. Prud’Homme, P. Michaud, E. Joussein, J. Clacens, S. Arii-Clacens, I. Sobrados, C. Peyratout, A. Smith, J. Sanz, and S. Rossignol: Structural characterization of geomaterial foams—Thermal behavior. J. Non-Cryst. Solids 357, 3637 (2011).

C. Bai, G. Franchin, H. Elsayed, A. Conte, and P. Colombo: High strength metakaolin-based geopolymer foams with variable macroporous structure. J. Eur. Ceram. Soc. 36, 4243 (2016).

A.M. Papadopoulos: State of the art in thermal insulation materials and aims for future developments. Energy Build. 37(1), 77 (2005).

E. Liefke: Industrial applications of foamed inorganic polymers. ’99 Geopolymer International Conference Proceedings (1999); p. 189.

H. Rahier, J. Wastiels, M. Biesemans, R. Willlem, G. Van Assche, and B. Van Mele: Reaction mechanism, kinetics and high temperature transformations of geopolymers. 42(9), 2982 (2007).

E. Papa, V. Medri, P. Benito, A. Vaccari, S. Bugani, J. Jaroszewicz, W. Swieszkowski, and E. Landi: Synthesis of porous hierarchical geopolymer monoliths by ice-templating. Microporous Mesoporous Mater. 215, 206 (2015).

M.S. Cilla, M.R. Morelli, and P. Colombo: Open cell geopolymer foams by a novel saponification/peroxide/gelcasting combined route. J. Eur. Ceram. Soc. 34, 3133 (2014).

G. Franchin and P. Colombo: Porous geopolymer components through inverse replica of 3D printed sacrificial templates. J. Ceram. Sci. Technol. 6, 105 (2015).

B.E. Glad and W.M. Kriven: Highly porous geopolymers through templating and surface interactions. J. Am. Ceram. Soc. 98, 2052 (2015).

J. Feng, R. Zhang, L. Gong, Y. Li, W. Cao, and X. Cheng: Development of porous fly ash-based geopolymer with low thermal conductivity. Mater. Des. 65, 529 (2015).

K. Ramamurthy and N. Narayanan: Influence of composition and curing on drying shrinkage of aerated concrete. Mater. Struct. 33, 243 (2000).

E.K.B. Ceron and H.T.E. Leonelli: Insulating behavior of metakaolin-based geopolymer materials assess with heat flux meter and laser flash techniques. J. Therm. Anal. Calorim. 108, 1189 (2012).

M. Yong, J. Liu, U.J. Alengaram, M.Z. Jumaat, and K.H. Mo: Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 72, 238 (2014).

Z. Zhang, J.L. Provis, A. Reid, and H. Wang: Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 56, 113 (2014).

T. Nie, L. Xue, M. Ge, H. Ma, and J. Zhang: Fabrication of poly(L-lactic acid) tissue engineering scaffolds with precisely controlled gradient structure. Mater. Lett. 176, 25 (2016).

Y. Zhang, D. Rodrigue, and A. Ait-Kadi: High-density polyethylene foams. I. Polymer and foam characterization. J. Appl. Polym. Sci. 90(8), 2111 (2003).

H. Jung, A. Fazio, N. Van Dooren, A. Delcroix, C. Faggio, R. Blust, and G. De Boeck: Kidney activity increases in copper exposed gold fish (Carassius auratus auratus). Comp. Biochem. Physiol., Part C: Pharmacol., Toxicol. Endocrinol. 190, 32 (2016).

P. Sepsi, E. Sárközi, K. Hrotkó, and L. Kardos: Monitoring of air pollution in budapest, Hungary using tree leaf samples—preliminary results. AgroLife Journal 4(1), 1 (2015).

F. Hagenkamp-korth, A. Haeussermann, and E. Hartung: Agriculture, ecosystems and environment effect of urease inhibitor application on urease activity in three different cubicle housing systems under practical conditions. Agric., Ecosyst. Environ. 202, 168 (2015).

L. Yin, H.X. Peng, S. Dhara, L. Yang, and B. Su: Natural additives in protein coagulation casting process for improved microstructural controllability of cellular ceramics. Composites, Part B 40(7), 638 (2009).

L. yan Yin, X. gui Zhou, J. Shan Yu, H. lei Wang, S. Zhao, Z. Luo, and B. Yang: New consolidation process inspired from making steamed bread to prepare Si3N4 foams by protein foaming method. J. Eur. Ceram. Soc. 33(7), 1387 (2013).

Z. Liu, N.N. Shao, D.M. Wang, J.F. Qin, T.Y. Huang, W. Song, M.X. Lin, J.S. Yuan, and Z. Wang: Fabrication and properties of foam geopolymer using circulating fluidized bed combustion fly ash. Int. J. Miner., Metall. Mater. 21(1), 89 (2014).

R.R. Lloyd, J.L. Provis, K.J. Smeaton, and J.S.J. van Deventer: Spatial distribution of pores in fly ash-based inorganic polymer gels visualised by Wood’s metal intrusion. Microporous Mesoporous Mater. 126, 32 (2009).

R. Rice: Comparison of physical property-porosity behaviour with minimum solid area models. J. Mater. Sci. 31, 1509 (1996).

R. Rice: Comparison of stress concentration versus minimum solid area based mechanical property–porosity relations. J. Mater. Sci. 28, 2187 (1993).

Y. Ge, X. Cui, Y. Kong, Z. Li, Y. He, and Q. Zhou: Porous geopolymeric spheres for removal of Cu(II) from aqueous solution: Synthesis and evaluation. J. Hazard. Mater. 283, 244 (2015).

M.V. Twigg and J.T. Richardson: Fundamentals and applications of structured ceramic foam catalysts. Ind. Eng. Chem. Res. 46(12), 4166 (2007).

F. Lucci, A. Della Torre, G. Montenegro, and P. Dimopoulos Eggenschwiler: On the catalytic performance of open cell structures versus honeycombs. Chem. Eng. J. 264, 514 (2015).

K.K. Al-Zboon, B.M. Al-smadi, and S. Al-Khawaldh: Natural volcanic tuff-based geopolymer for Zn removal: Adsorption isotherm, kinetic, and thermodynamic study. Water, Air, Soil Pollut. 227(7), 1 (2016).

ACKNOWLEDGMENTS

Chengying Bai gratefully acknowledges the financial support of the China Scholarship Council (CSC) (No. 201407565009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bai, C., Franchin, G., Elsayed, H. et al. High-porosity geopolymer foams with tailored porosity for thermal insulation and wastewater treatment. Journal of Materials Research 32, 3251–3259 (2017). https://doi.org/10.1557/jmr.2017.127

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.127