Abstract

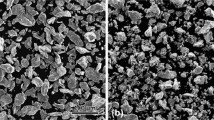

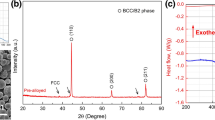

The NbCr2 Laves phase was fabricated by spark plasma sintering (SPS) using spherical Nb and Cr powders. The experimental results revealed that increasing the sintering temperature to 1773 K can result in the formation of NbCr2 Laves phase as major phase, but it always appeared with trace amounts of Nb and Cr solid solutions. Based on the theoretical calculations, the residual of Nb and Cr solid solutions was attributed to the inhomogeneous distribution of temperature increase from the particle-contacting surface to the center of particle when pulsed current passed through. Moreover, the hardness and fracture toughness of the SPS-processed NbCr2 attained 14.05 ± 0.67 GPa and 8.9 MPa·m1/2, which were 1.6 and 7.4 times of the as-cast NbCr2 Laves phase (1.2 MPa·m1/2). The formation of ductile Nb and Cr solid solutions and fine grains were considered to be the reason for the remarkable enhancements in mechanical properties.

Similar content being viewed by others

References

Y.L. Xue, S.M. Li, H. Zhong, and H.Z. Fu: Characterization of fracture toughness and toughening mechanisms in Laves phase Cr2Nb based alloys. Mater. Sci. Eng., A 638, 340 (2015).

W. Zhong, W. Wang, X. Yang, W. Li, W. Yan, W. Sha, W. Wang, Y. Shan, and K. Yang: Relationship between Laves phase and the impact brittleness of P92 steel reevaluated. Mater. Sci. Eng., A 639, 252 (2015).

L.N. Jia, J.F. Weng, Z. Li, Z. Hong, L.F. Su, and H. Zhang: Room temperature mechanical properties and high temperature oxidation resistance of a high Cr containing Nb-Si based alloy. Mater. Sci. Eng., A 623, 32 (2015).

S.Q. Lu, H.Z. Zheng, and M.W. Fu: The fracture toughness of hot-pressed NbCr2 alloys doped by rare earth yttrium. Scr. Mater. 61, 205 (2009).

X.W. Nie, S.Q. Lu, and K.L. Wang: Effect of mechanical alloying on the structure and properties of NbCr2 Laves phase fabricated by hot pressing. Powder Technol. 184, 333 (2008).

T. Ohta, Y. Nakagawa, Y. Kaneno, H. Inoue, T. Takasugi, and W.Y. Kim: Microstructures and mechanical properties of NbCr2 and ZrCr2 Laves phase alloys prepared by powder metallurgy. J. Mater. Sci. 38, 657 (2003).

M. Takeyama and C.T. Liu: Microstructure and mechanical properties of Laves-phase alloys based on Cr2Nb. Mater. Sci. Eng., A 132, 61 (1991).

X.W. Nie, S.Q. Lu, K.L. Wang, T.C. Chen, and C.L. Niu: Fabrication and toughening of NbCr2 matrix composites alloyed with Ni obtained by powder metallurgy. Mater. Sci. Eng., A 502, 85 (2009).

S.Q. Lu, H.Z. Zheng, L.P. Deng, and J. Yao: Effect of silicon on the fracture toughness and oxidation behavior of hot pressed NbCr2 alloys. Mater. Des. 51, 432 (2013).

K.W. Li, S.M. Li, X.B. Wang, H. Zhong, Y.L. Xue, and H.Z. Fu: Microstructure and mechanical properties of Cr2Nb-based Laves phase alloys prepared by laser surface remelting. JOM 66, 1886 (2014).

X. Xiao, S.Q. Lu, P. Hu, M.G. Huang, X.W. Nie, and M.W. Fu: The effect of hot pressing time on the microstructure and properties of Laves phase NbCr2 alloys. Mater. Sci. Eng., A 485, 80 (2008).

L. Ge, G. Subhash, R.H. Baney, and J.S. Tulenko: Influence of processing parameters on thermal conductivity of uranium dioxide pellets prepared by spark plasma sintering. J. Eur. Ceram. Soc. 34, 1791 (2014).

C. Wang, L. Cheng, and Z. Zhao: FEM analysis of the temperature and stress distribution in spark plasma sintering: Modelling and experimental validation. Comput. Mater. Sci. 49, 351 (2010).

F. Zhang, F. Ahmed, G. Holzhüter, and E. Burkel: Growth of diamond from fullerene C60 by spark plasma sintering. J. Cryst. Growth 340, 1 (2012).

U. Anselmi-Tamburini, Y. Kodera, M. Gasch, C. Unuvar, Z.A. Munir, M. Ohyanagi, and S.M. Johnson: Synthesis and characterization of dense ultra-high temperature thermal protection materials produced by field activation through spark plasma sintering (SPS): I. Hafnium diboride. J. Mater. Sci. 41, 3097 (2006).

R. Orrù, R. Licheri, A.M. Locci, A. Cincotti, and G. Cao: Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater. Sci. Eng., R 63, 127 (2009).

N.S. Karthiselva, B.S. Murty, and S.R. Bakshi: Low temperature synthesis of dense and ultrafine grained zirconium diboride compacts by reactive spark plasma sintering. Scr. Mater. 110, 78 (2016).

Y. Sun, J. Haley, K. Kulkarni, M. Aindow, and E.J. Lavernia: Influence of electric current on microstructure evolution in Ti/Al and Ti/TiAl3 during spark plasma sintering. J. Alloys Compd. 648, 1097 (2015).

R. Kumar, A.K. Chaubey, S. Bathula, B.B. Jha, and A. Dhar: Synthesis and characterization of Al2O3-TiC nano-composite by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 54, 304 (2016).

A.M. Bolarín-Miró, F. Sánchez-De Jesús, C.A. Cortés-Escobedo, S. Díaz-De la Torre, and R. Valenzuela: Synthesis of M-type SrFe12O19 by mechanosynthesis assisted by spark plasma sintering. J. Alloys Compd. 643(Suppl 1), S226 (2015).

W. Liu, Y.M. Fu, and J.B. Sha: Microstructure and mechanical properties of Nb–Si alloys fabricated by spark plasma sintering. Prog. Nat. Sci. 23, 55 (2013).

A. Couret, G. Molénat, J. Galy, and M. Thomas: Microstructures and mechanical properties of TiAl alloys consolidated by spark plasma sintering. Intermetallics 16, 1134 (2008).

N. Chawake, N.T.B.N. Koundinya, A.K. Srivastav, and R.S. Kottada: On correlation between densification kinetics during spark plasma sintering and compressive creep of B2 aluminides. Scr. Mater. 107, 63 (2015).

T. Shanmugasundaram, J. Guyon, J.P. Monchoux, A. Hazotte, and E. Bouzy: On grain refinement of a γ-TiAl alloy using cryo-milling followed by spark plasma sintering. Intermetallics 66, 141 (2015).

J. Bu, P.G. Jönsson, and Z. Zhao: Dense and translucent BaZrxCe0.8−xY0.2O3−δ (x = 0.5, 0.6, 0.7) proton conductors prepared by spark plasma sintering. Scr. Mater. 107, 145 (2015).

X. Li and B. Bhushan: A review of nanoindentation continuous stiffness measurement technique and its applications. Mater. Charact. 48, 11 (2002).

G.R. Anstis, P. Chantikul, B.R. Lawn, and D.B. Marshall: A critical evaluation of indentation techniques for measuring fracture toughness: I, Direct crack measurements. J. Am. Ceram. Soc. 64, 533 (1981).

J.R. Groza: Consolidation of atomized NiAl powders by plasma activated sintering process. Scr. Metall. Mater. 30, 47 (1994).

T. Tsuchida, R. Furuichi, and T. Ishii: Reactivity of η-, γ-, and α-Al2O3 for ZnAl2O4 formation. Z. Anorg. Allg. Chem. 415, 175 (1975).

C. Schmetterer, A. Khvan, A. Jacob, B. Hallstedt, and T. Markus: A new theoretical study of the Cr-Nb system. J. Phase Equilib. Diffus. 35, 434 (2014).

X. Liu, X. Song, and J. Zhang: Neck formation and self-adjusting mechanism of neck growth of conducting powders in spark plasma sintering. J. Am. Ceram. Soc. 89, 494 (2006).

M. Suárez, A. Fernández, J.L. Menéndez, R. Torrecillas, H.U. Kessel, J. Hennicke, R. Kirchner, and T. Kessel: Challenges and opportunities for spark plasma sintering: A key technology for a new generation of materials. In Sintering Applications, Burcu Ertuğ, ed. (Intech, 2013). doi: https://doi.org/10.5772/53706.

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

D. Tabor: The Hardness of Metals (Oxford University Press, Oxford, 1951).

F. Chu, Y. He, D.J. Thoma, and T.E. Mitchell: Elastic constants of the C15 laves phase compound NbCr2. Scr. Metall. Mater. 33, 1295 (1995).

S. Lee, P.K. Liaw, C.T. Liu, and Y.T. Chou: Cracking in Cr-Cr2Nb eutectic alloys due to thermal stresses. Mater. Sci. Eng., A 268, 184 (1999).

ACKNOWLEDGMENTS

This research was financially supported by the fund of the State Key Laboratory of Solidification Processing in NWPU (SKLSP201507, SKLSP201516), the Youth Foundation of Taiyuan University of Technology (2014TD010) and the Qualified Personnel Foundation of Taiyuan University of Technology (tyut-rc201421a).

Author information

Authors and Affiliations

Corresponding author

APPENDIX

APPENDIX

The sintering setup, thermophysical, and electrical parameters used in the modeling are listed below:

-

d (sample diameter, m) = 2.0 × 10−2

-

Ss (sample cross-sectional area, m2) = 3.14 × 10−4

-

Sd (die cross-sectional area, m2) = 1.26 × 10−3

-

ρs1 (Cr electrical resistivity, Ω m) = 1.29 ×10−7 + 3.87 × 10−10T

-

ρs2 (Nb electrical resistivity, Ω m) = 1.25 × 10−7 + 5.0 × 10−10T

-

ρsd (graphite electrical resistivity, Ω m) = 21 − 3 × 10−2T + 2 × 10−5T2 − 6.4 × 10−9T3 + 7.8 × 10−13T4

-

Δt (current duration, ms) = 40 × 3.3 = 132

-

CP,graphite [specific heat capacity at constant pressure of graphite, J/(g K)] = 0.71

-

CP,Nb [specific heat capacity at constant pressure of Nb, J/(g K)] = 0.26

-

CP,Cr [specific heat capacity at constant pressure of Cr, J/(g K)] = 0.45

-

ρm,graphite (mass density of graphite, g/m3) = 2.1 × 106

-

ρm,Nb (mass density of Nb, g/m3) = 8.57 × 106

-

ρm,Cr (mass density of Cr, g/m3) = 7.22 × 106

Rights and permissions

About this article

Cite this article

Li, K.W., Li, S.M., Gao, K. et al. Synthesis and characterization of NbCr2 Laves phase produced by spark plasma sintering. Journal of Materials Research 31, 380–387 (2016). https://doi.org/10.1557/jmr.2016.6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.6