Abstract

Laves phase NbCr2-based composites toughened with different volume fractions of Cr phase were fabricated by spark plasma sintering (SPS). The microstructural evolution and mechanical properties of these spark plasma sintered NbCr2/Cr composites were investigated. The mechanical properties evaluations indicate that the introducing of Cr phase consolidated by SPS has a beneficial effect on the mechanical properties of the NbCr2 Laves phase. When the content of Cr phase in the NbCr2 Laves phase increases to 30 wt%, the hardness measured by a Berkovich nanoindenter operated with the continuous stiffness measurements mode attains the maximum value of 13.44 GPa, which is increased by about 56% over the as-cast NbCr2 Laves phase. More importantly, the room-temperature fracture toughness of the NbCr2-30wt%Cr alloy is increased to 18.9 MPa·m1/2, which is 16 times higher than that of the as-cast NbCr2 Laves phase (1.2 MPa·m1/2). The microstructural analysis indicates that the residual of Cr phase and formation of Nb solid solution can provide remarkable toughening of the NbCr2 Laves phase by fine grain toughening, dual ductile phase toughening, and interface toughening mechanisms. A possible formation mechanism of Nb solid solution during SPS has been proposed by considering the composition distribution.

Similar content being viewed by others

References

C. Jiang: Site preference of early transition metal elements in C15 NbCr2. Acta Mater. 55, 1599 (2007).

A.V. Kazantzis, M. Aindow, I.P. Jones, and G.K. Triantafyllidis, and J.Th.M. De Hosson: The mechanical properties and the deformation microstructures of the C15 Laves phase Cr2Nb at high temperatures. Acta Mater. 55, 1873 (2007).

X.W. Nie, S.Q. Lu, K.L. Wang, T.C. Chen, and C.L. Niu: Fabrication and toughening of NbCr2 matrix composites alloyed with Ni obtained by powder metallurgy. Mater. Sci. Eng., A 502, 85 (2009).

K.W. Li, S.M. Li, K. Gao, and D.Q. Gong: Synthesis and characterization of NbCr2 Laves phase produced by spark plasma sintering. J. Mater. Res. 31, 380 (2016).

P. Shayesteh, S. Mirdamadi, and H. Razavi: Study the effect of mechanical alloying parameters on synthesis of Cr2Nb–Al2O3 nanocomposite. Mater. Res. Bull. 49, 50 (2014).

M. Takeyama and C.T. Liu: Microstructure and mechanical properties of Laves-phase alloys based on Cr2Nb. Mater. Sci. Eng., A 132, 61 (1991).

K.W. Li, S.M. Li, Y.L. Xue, and H.Z. Fu: Microstructure characterization and mechanical properties of a Laves-phase alloy based on Cr2Nb. Int. J. Refract. Met. Hard Mater. 36, 154 (2013).

K.W. Li, S.M. Li, Y.L. Xue, and H.Z. Fu: Microstructure and mechanical properties of arc melted Cr–Cr2Nb hypoeutectic alloy. Mater. Sci. Technol. 29, 742 (2013).

C.M. Cady, K.C. Chen, P.G. Kotula, M.E. Mauro, and D.J. Thoma: Microstructures and mechanical properties of two-phase alloys based on NbCr2. MRS Proc. 552 (1998). doi: https://doi.org/10.1557/PROC-552-KK7.4.1.

N. Aoyama and S. Hanada: Microstructure and strength of NbCr2/Cr composites. Mater. Trans. 38, 155 (1997).

F. Stein, C. He, and I. Wossack: The liquidus surface of the Cr–Al–Nb system and re-investigation of the Cr–Nb and Al–Cr phase diagrams. J. Alloys Compd. 598, 253 (2014).

X.D. Li and B. Bhushan: A review of nanoindentation continuous stiffness measurement technique and its applications. Mater. Charact. 48, 11 (2002).

G.R. Anstis, P. Chantikul, B.R. Lawn, and D.B. Marshall: A critical evaluation of indentation techniques for measuring fracture toughness: I, direct crack measurements. J. Am. Ceram. Soc. 64, 533 (1981).

M. Sakai and R.C. Bradt: Fracture toughness testing of brittle materials. Int. Mater. Rev. 38, 53 (1992).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

D. Tabor: The Hardness of Metals (Oxford University Press, Oxford, 1951).

X. Xiao, S.Q. Lu, P. Hu, M.G. Huang, X.W. Nie, and M.W. Fu: The effect of hot pressing time on the microstructure and properties of Laves phase NbCr2 alloys. Mater. Sci. Eng., A 485, 80 (2008).

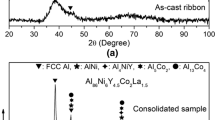

X.F. Wang, K. Wang, Z.D. Li, X.F. Wang, D. Wang, and F.S. Han: Synthesis and mechanical properties of bulk Al76Ni8Ti8Zr4Y4 alloy fabricated by consolidation of mechanically alloyed amorphous powders. J. Alloys Compd. 632, 617 (2015).

N. Van Steenberge, J. Sort, A. Concustell, J. Das, S. Scudino, S. Suriñach, J. Eckert, and M.D. Baró: Dynamic softening and indentation size effect in a Zr-based bulk glass-forming alloy. Scr. Mater. 56, 605 (2007).

J.I. Jang, B.G. Yoo, Y.J. Kim, J.H. Oh, I.C. Choi, and H. Bei: Indentation size effect in bulk metallic glass. Scr. Mater. 64, 753 (2011).

F.C.A. Ormeci, J.M. Wills, S.P. Chen, R.C. Albers, D.J. Thoma, and T.E. Mitchell: Elastic constants of a Laves phase compound: C15 NbCr2. MRS Proc. 460, 460 (1996).

F. Chu, Y. He, D.J. Thoma, and T.E. Mitchell: Elastic constants of the C15 laves phase compound NbCr2. Scr. Metall. Mater. 33, 1295 (1995).

D.L. Davidson, K.S. Chan, and D.L. Anton: The effects on fracture toughness of ductile-phase composition and morphology in Nb–Cr–Ti and Nb–Si in situ composites. Metall. Mater. Trans. A 27, 3007 (1996).

S. Lee, P.K. Liaw, C.T. Liu, and Y.T. Chou: Cracking in Cr–Cr2Nb eutectic alloys due to thermal stresses. Mater. Sci. Eng., A 268, 184 (1999).

X.L. Song, X.M. Liu, and J.X. Zhang: Neck formation and self-adjusting mechanism of neck growth of conducting powders in spark plasma sintering. J. Am. Ceram. Soc. 89, 494 (2006).

Y.D. Yin, R.M. Rioux, C.K. Erdonmez, S. Hughes, G.A. Somorjai, and A.P. Alivisatos: formation of hollow nanocrystals through the nanoscale Kirkendall effect. Science 304, 711 (2004).

ACKNOWLEDGMENT

This research was financially supported by the fund of the State Key Laboratory of Solidification Processing in NWPU (SKLSP201507), the Youth Foundation of Taiyuan University of Technology (2014TD010) and the Qualified Personnel Foundation of Taiyuan University of Technology (tyut-rc201421a).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, K., Hao, R., Di, C. et al. Microstructure and mechanical properties of Laves phase NbCr2-based composites toughened with Cr phase fabricated by spark plasma sintering. Journal of Materials Research 31, 2214–2222 (2016). https://doi.org/10.1557/jmr.2016.231

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.231