Abstract

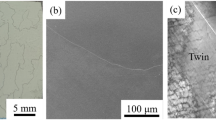

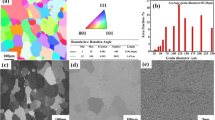

The deformation behaviors (flow behavior, power dissipation, dynamic recrystallization, and microstructure evolution) of a typical powder metallurgy nickel-based superalloy were investigated in compression tests at temperatures range of 1020–1140 °C and strain rates range of 0.001–1.0 s−1 with the true strains of 0.3, 0.5, and 0.7, respectively. The efficiency of power dissipation can be shown by the power dissipation maps at different true strains. The results showed that true strain had a great effect on the power dissipation. Besides, the deformed microstructures were investigated. The processes of microstructure evolution at different deformation temperatures and strain rates are different. The continuous dynamic recrystallization takes place at the deformation condition of 1080 °C/0.1 s−1. The fine and uniform dynamic recrystallized grains gradually replace the pre-existing grains with the increase of true strain. The discontinuous dynamic recrystallization takes place at the deformation condition of 1110 °C/0.001 s−1. The fine dynamic recrystallized grains grow up and a part of new fine grains appear in the dynamic recrystallized grains because of the periodic dynamic recrystallization.

Similar content being viewed by others

References

F.L. Jiang, H. Zhang, L.X. Li, and J.H. Chen: The kinetics of dynamic and static softening during multistage hot deformation of 7150 aluminum alloy. Mater. Sci. Eng., A 552, 269–275 (2012).

X.M. Chen, Y.C. Lin, M.S. Chen, H.B. Li, D.X. Wen, J.L. Zhang, and M. He: Microstructural evolution of a nickel-based superalloy during hot deformation. Mater. Des. 77, 41–49 (2015).

Y.C. Lin, L.T. Li, Y.X. Fu, and Y.Q. Jiang: Hot compressive deformation behavior of 7075 Al alloy under elevated temperature. J. Mater. Sci. 47 (3), 1306–1318 (2012).

L. Tian, Q. Ao, and S.L. Li: Effect of austenitic state on microstructure and mechanical properties of martensite/bainite steel. J. Mater. Res. 29 (7), 887–895 (2014).

Z.L. Li, Q.Y. Xu, and B.C. Liu: Microstructure simulation on recrystallization of an as-cast nickel based single crystal superalloy. Comput. Mater. Sci. 107, 122–133 (2015).

Y.Z. Liu, X.B. Hu, S.J. Zheng, Y.L. Zhu, H. Wei, and X.L. Ma: Microstructural evolution of the interface between NiCrAlY coating and superalloy during isothermal oxidation. Mater. Des. 80, 63–69 (2015).

W. Sun, X.Z. Qin, J.T. Guo, L.H. Lou, and L.Z. Zhou: Thermal stability of primary MC carbide and its influence on the performance of cast Ni-base superalloys. Mater. Des. 69, 81–88 (2015).

Q. Bai, J. Lin, J. Jiang, T.A. Dean, J. Zou, and G. Tian: A study of direct forging process for powder superalloys. Mater. Sci. Eng., A 621, 68–75 (2015).

L.T. Chang, W.R. Sun, Y.Y. Cui, F.Q. Zhang, and R. Yang: Effect of heat treatment on microstructure and mechanical properties of the hot-isostatic-pressed Inconel 718 powder compact. J. Alloys Compd. 590, 227–232 (2014).

M.H. Wang, Y.F. Li, W.H. Wang, J. Zhou, and A. Chiba: Quantitative analysis of work hardening and dynamic softening behavior of low carbon alloy steel based on the flow stress. Mater. Des. 45, 384–392 (2013).

L.X. Li, B. Ye, S. Liu, S.D. Hu, and B. Li: Inverse analysis of the stress–strain curve to determine the materials models of work hardening and dynamic recovery. Mater. Sci. Eng., A 636, 243–248 (2015).

K. Wu, G.Q. Liu, B.F. Hu, F. Li, Y.W. Zhang, Y. Tao, and J.T. Liu: Hot compressive deformation behavior of a new hot isostatically pressed Ni–Cr–Co based powder metallurgy superalloy. Mater. Des. 32, 1872–1879 (2011).

D.F. Li, Q.M. Guo, S.L. Guo, H.J. Peng, and Z.G. Wu: The microstructure evolution and nucleation mechanisms of dynamic recrystallization in hot-deformed Inconel 625 superalloy. Mater. Des. 32, 696–705 (2011).

L.H. Rettberg and T.M. Pollock: Localized recrystallization during creep in nickel-based superalloys GTD444 and René N5. Acta Mater. 73, 287–297 (2014).

Z.W. Cai, F.X. Chen, and J.Q. Guo: Constitutive model for elevated temperature flow stress of AZ41M magnesium alloy considering the compensation of strain. J. Alloys Compd. 648, 215–222 (2015).

Y.H. Liu, Y.Q. Ning, Z.K. Yao, and M.W. Fu: Hot deformation behavior of the 1.15C–4.00Cr–3.00V–6.00W–5.00Mo powder metallurgy high speed steel. Mater. Des. 54, 854–863 (2014).

H. Jiang, J.X. Dong, M.C. Zhang, L. Zheng, and Z.H. Yao: Hot deformation characteristics of alloy 617B nickel-based superalloy: A study using processing map. J. Alloys Compd. 647, 338–350 (2015).

Y. Wang, Q.L. Pan, Y.F. Song, C. Li, and Z.F. Li: Hot deformation and processing maps of X-750 nickel-based superalloy. Mater. Des. 51, 154–160 (2013).

Y.H. Liu, Y.Q. Ning, Y. Nan, H.Q. Liang, Y.Z. Li, and Z.L. Zhao: Characterization of hot deformation behavior and processing map of FGH4096-GH4133B dual alloys. J. Alloys Compd. 633, 505–515 (2015).

X. Shang, J. Zhou, X. Wang, and Y. Luo: Optimizing and identifying the process parameters of AZ31 magnesium alloy in hot compression on the base of processing maps. J. Alloys Compd. 629, 155–161 (2015).

Y.Q. Ning, C. Zhou, H.Q. Liang, and M.W. Fu: Abnormal flow behavior and necklace microstructure of powder metallurgy superalloys with previous particle boundaries (PPBs). Mater. Sci. Eng., A 652, 84–91 (2016).

H.Y. Zhang, S.H. Zhang, M. Cheng, and Z.X. Li: Deformation characteristics of δ phase in the delta-processed Inconel 718 alloy. Mater. Charact. 61, 49–53 (2010).

ACKNOWLEDGMENTS

This work was financially supported by the national natural science foundation of China (Grant No. 51101119 and Grant No. 51175431), the postdoctoral science foundation of China (Grant No. 2015M570851), and the fundamental research funds for the central universities (Grant No. 3102016ZY012). Also, we would like to thank the funding support by the Hong Kong scholar program (Grant No. XJ2014047 and G-YZ68).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Ning, Y., Yao, Z. et al. Dynamic recrystallization and microstructure evolution of a powder metallurgy nickel-based superalloy under hot working. Journal of Materials Research 31, 2164–2172 (2016). https://doi.org/10.1557/jmr.2016.204

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.204