Abstract

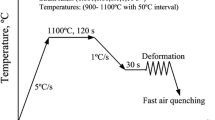

Hot deformation behavior of Incoloye028 alloy was investigated by conducting hot compression tests on Gleeble-3800 simulator in the temperature range of 1223–1473 K and the strain rate range of 0.1–50 s−1. True stress–true strain curves showed that the flow stress increases with the decrease of deformation temperature and the increase of strain rate. The constitutive equations of Incoloy028 alloy were obtained by introducing Zener–Hollomom parameter, the flow behavior can be described by the hyperbolic sine function and the activation energy changes with strain rate and temperature significantly. The hot working maps of Incoloy028 alloy were proposed on basis of dynamic materials model. The hot working maps for different strains indicated that there were two instability zones, one zone is in the temperatures range of 1423–1473 K and strain rate range of 0.1–50 s−1, and another zone is in the temperature range of 1223–1423 K and strain rate range of 0.6–1 s−1. The reasonable hot working temperature range is 1423–1473 K when strain rate is more than 50 s−1.

Similar content being viewed by others

References

H.D. Liu, D.Z. Wang, and H.D. Wei: Material selection and application of high performance stainless steels used in sour oil and gas fields. Corros. Prot. 32 (10), 817–821 (2011).

C.Y. Sun, J.R. Liu, R. Li, Q.D. Zhang, and J.X. Dong: Effect of process parameters on the exit temperature of IN690 alloy tubes during hot extrusion. J. Univ. Sci. Technol. Beijing 32 (11), 1483–1488 (2010).

C.Y. Sun, J.R. Liu, R. Li, and Q.D. Zhang: Constitutive modeling for elevated temperature flow behavior of Incoloy 800H superalloy. Acta Metall. Sin. 47 (2), 191–196 (2011).

C.Y. Sun, G. Liu, Q.D. Zhang, R. Li, and L.L. Wang: Determination of hot deformation behavior and hot working maps of IN 028 alloy using isothermal hot compression test. Mater. Sci. Eng., A 595 (10), 92–98 (2014).

S.V.S.N. Murty and B.N. Rao: On the development of instability criteria during hotworking with reference to IN 718. Mater. Sci. Eng., A 254 (15), 76–82 (1998).

D.Y. Cai, L.Y. Xiao, W.C. Liu, G.D. Sun, and M. Yao: Characterization of hot deformation behavior of a Ni-base superalloy using processing map. Mater. Des. 30 (3), 921–925 (2009).

C.M. Sellars and W.J.M. Tegart: On the mechanism of hot deformation. Acta Metall. 14 (9), 1136–1138 (1966).

H.J. McQueen and N.D. Ryan: Constitutive analysis in hot working. Mater. Sci. Eng., A 322 (21), 43–63 (2002).

C. Zener and J.H. Hollomon: Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 15 (1), 22–32 (1944).

H. Takuda, H. Fujimoto, and N. Hatta: Modeling on flow stress of Mg–Al–Zn alloys at elevated temperatures. J. Mater. Process. Technol. 80/81 (1), 513–516 (1998).

A. Galiyev, R. Kaibyshev, and T. Saikai: Continuous dynamic recrystallization in magnesium alloy. Mater. Sci. Forum 419/422, 509–514 (2003).

T. Sakai and J.J. Jonas: Dynamic recrystallization: Mechanical and microstructrural considerations. Acta Mater. 32, 189–209 (1984).

Y.V.R.K. Prasad and S. Sasidhara: Hot working guide: A compendium of hot working maps (ASM, America, 1997).

N. Srinivasan, Y. Prasad, and R.P. Rama: Hot deformation behaviour of Mg–3Al alloy—a study using processing map. Mater. Sci. Eng., A 476 (1), 146–156 (2008).

Y.V.R.K. Prasad and T. Seshacharyulu: Hot working maps for hot working of titanium alloys. Mater. Sci. Eng., A 243 (15), 82–86 (1998).

Y.V.R.K. Prasad and T. Seshacharyulu: Modeling of hot deformation for microstructural control. Int. Mater. Rev. 43 (6), 243–258 (1998).

ACKNOWLEDGMENTS

The authors are grateful for the financial support of Foundation of National Natural Science (51305228) and the assistance of Lian Jie in compression tests in this paper. The authors appreciate Miss. Shujuan Dong from Wuhan University of technology for her contribution to the English revision.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Z., Tuo, L. & Zhou, G. Research on constitutive equations and hot working maps of Incoloy028 alloy based on hot compression tests. Journal of Materials Research 31, 1501–1509 (2016). https://doi.org/10.1557/jmr.2016.157

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.157