Abstract

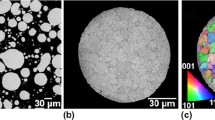

The microstructural evolution during spark plasma sintering of ultrafine WC–1 wt% Si (n-WC–Si) is presented. At 1323 K (T < TmSi), extensive stacking faults on the \(\left\{{10\bar 10} \right\}\) prismatic planes are observed. The defect microstructure can be described as a combined shear of \(1/6\left\langle {\bar 12\bar 13} \right\rangle \) on the prism planes and simultaneous out-diffusion of carbon through the faults to the interparticle boundaries. At temperatures near TmSi (1673 K), a large fraction of abnormally grown platelets is observed. These platelets contain a single planar defect on their basal planes, described by a \(1/3\left\langle {10\bar 10} \right\rangle \) translation of the carbon atoms across a Σ1 grain boundary (GB). Three factors contribute to the abnormally high density of platelets: (i) the low-temperature prismatic dislocations interact to form facet-roughening steps/kinks that act as nucleation sites, (ii) a liquid phase triggers an increased growth rate in the vicinity of the Si inclusions, and (c) the basal twin produces a re-entrant edge for 2D nucleation.

Similar content being viewed by others

References

X. Yuan, G. Rohrer, X. Song, H. Chien, and J. Li: Modelling the interface area aspect ratio of carbide grains in WC–Co composites. Int. J. Refract. Met. Hard Mater. 44, 7 (2014).

B.-K. Yoon, B.-A. Lee, and S.-J.L. Kang: Growth behavior of rounded (Ti, W)C and faceted WC grains in a Co matrix during liquid phase sintering. Acta Mater. 53, 4677 (2005).

Z. Li, C. Shu, W. Yuan-jie, Y. Xian-wang, and X. Xiang-jun: Tungsten carbide platelet-containing cemented carbide with yttrium containing dispersed phase. Trans. Nonferrous Met. Soc. China 18, 104 (2008).

S.I. Cha and S.H. Hong: Microstructures of binder-less tungsten carbides sintered by spark plasma sintering process. Mater. Sci. Eng., A 356, 381 (2003).

L. Girardini, M. Zadra, F. Casari, and A. Molinari: SPS, binderless WC powders and the problem of the sub-carbide. Met. Powder Rep. 63, 18 (2008).

W. Jo, D.-Y. Kim, and N.-M. Hwang: Effect of interface structure on the microstructural evolution of ceramics. J. Am. Ceram. Soc. 89, 2369 (2006).

S.-J. Kang, M.-G. Lee, and S.-M. Yan: Microstructural evolution during sintering with control of the interface structure. J. Am. Ceram. Soc. 92, 1464 (2009).

K.-S. Oh, J.-Y. Jun, D.-Y. Kim, and N.M. Hwang: Shape dependence of the coarsening behavior of niobium carbide grains dispersed in liquid iron matrix. J. Am. Ceram. Soc. 83, 317 (2000).

A.K. Nanda Kumar, M. Watabe, and K. Kurokawa: Effect of boron on the microstructure of spark plasma sintered ultrafine WC. Vacuum 88, 88 (2013).

S. Lay and M. Loubradou: Structural analysis on planar defects formed in WC platelets in Ti-doped WC–Co. J. Am. Ceram. Soc. 89, 3229 (2006).

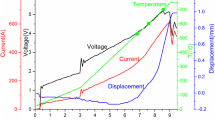

A.K. Nanda Kumar, M. Watabe, and K. Kurokawa: The sintering kinetics of n-WC–Si and n-WC–B. J. App. Plasma Sci. 18, 83 (2010).

A.K. Nanda Kumar, M. Watabe, A. Yamauchi, A. Kobayashi, and K. Kurokawa: Spark plasma sintering of binderless n-WC and n-WC–X (X = Nb, Re, Ta, Ti, B, Si). Trans. Joining and Welding Research Institute, Japan 39, 47 (2010).

A. Nino, Y. Nakaibayashi, S. Sugiyama, and H. Taimatsu: Microstructure and mechanical properties of WC–SiC composites. Mater. Trans. 52, 1641 (2011).

S. Sugiyama, D. Kudo, and H. Taimatsu: Preparation of WC–SiC whisker composites by hot pressing and their mechanical properties. Mater. Trans. 49, 1644 (2008).

A.K. Nanda Kumar, M. Watabe, and K. Kurokawa: Influence of silicon on the microstructure and sintering kinetics of ultrafine tungsten carbide powders. Philos. Mag. A, 92, 3950 (2012).

K.-R. Lai and T.-Y. Tien: Kinetics of β-Si3N4 grain growth in Si3N4 ceramics sintered under high nitrogen pressure. J. Am. Ceram. Soc. 76, 91 (1993).

M.K. Hibbs and R. Sinclair: Room temperature deformation mechanisms and the defect structure of tungsten carbide. Acta Metall. 29, 1645 (1981).

V. Jayaram, R. Sinclair, and J. Rowcliffe: Deformation enhanced decarburization of WC–Co. Scr. Metall. 20, 55 (1986).

Y. Zhi-min, M. Chang-hui, D. Jun, M. Daniel, C. Yannick, H. Serge, and H. Martin: Trans. Nonferrous Met. Soc. China. 11, 529 (2001).

P.L. Gai, C.C. Torardi, and E.D. Boyes: Turning points in solid-state materials and surface science, K.D.M. Harris and P.P. Edwards eds.; RSC Publication, 2008; p. 745.

Y. Gao, X. Song, X. Liu, C. Wei, H. Wang, and G. Guo: On the formation of WC1− x in nanocrystalline cemented carbides. Scr. Mater. 68, 108 (2013).

T.V. Vineesh, M. Praveen Kumar, C. Takahashi, G. Kalita, S. Alwarappan, D.K. Pattanayak, and T.N. Narayanan: Bifunctional electrocatalytic activity of boron-doped graphene derived from boron carbide. Adv. Energy Mater. 5, 1500658 (2015).

J.D. Bolton and M. Redington: Plastic deformation mechanisms in tungsten carbide. J. Mater. Sci. 15, 3150 (1980).

R.M. Greenwood, M.H. Loretto, and R.E. Smallman: The defect structure of tungsten carbide in deformed tungsten carbide-cobalt composites. Acta Metall. 30, 1193 (1982).

F.R.N. Nabarro, S. Bartolucci Luyckx, and U.V. Waghmare: Slip in tungsten monocarbide II. A first-principles study. Mater. Sci. Eng., A 483–484, 9 (2008).

D. Lewis and L.J. Porter: Plastic deformation in tungsten carbide. J. Appl. Crystallogr. 2, 249 (1969).

M. Sommer, W.-D. Schubert, E. Zobetz, and P. Warbichler: On the formation of very large crystals during sintering of ultrafine WC–Co alloys. Int. J. Refract. Met. Hard Mater. 20, 41–50 (2002).

R.M. Young and R. McPherson: Temperature gradient-driven diffusion in rapid-rate sintering. J. Am. Ceram. Soc. 72, 1080 (1989).

E.A. Olevsky and L. Froyen: Impact of thermal diffusion on densification during SPS. J. Am. Ceram. Soc. 92 (S1), S122 (2009).

R.J.L. Andon, J.F. Martin, K.C. Mills, and T.R. Jenkins: Heat capacity and entropy of tungsten carbide. I. Chem. Thermodyn. 7, 1079 (1975).

V.G. Grebenkina and E.N. Denbnovetskaya: Temperature coefficient of electrical resistivity of some complex carbides. Translated from Poroshkovaya Met. 3(63) 34 (1968).

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

APPENDIX A1

APPENDIX A1

The local temperature gradient in the sample was calculated by using the formula developed by Olevsky and Froyen.29 In their model of heat conduction in SPS, the local temperature gradient, without considering heat loss is given by:

where G is the grain size, rp is the pore radius, C is the specific heat capacity, T0 is the temperature from which sintering is assumed to start (873 K, in this case), E is the electric field (V/m), λe is the electrical conductivity, Δt is the total (ON + OFF) pulse sequence duration, and n is the number of pulses required to reach the desired temperature. In our experiments, we used a pulse ON/OFF ratio of 12/2 which corresponds to 39.6 ms ON time and 6.6 ms OFF time. The ON pulse comprises twelve 3.3 ms pulses. Other approximate values were also plugged in: G ≈ 100 nm, rp ≈ 50 nm, Δt = 46.2 ms, n = 120220, E ≈ 1000 V/m. The values of C and λe were obtained from the literature: C1300K ≈ 0.0175 J/K/m3.30 For a sample with residual porosity P, the heat capacity is given by C = (1 − P)C1300K.29 Data on the electrical resistivity of WC at high temperatures was largely unavailable. Therefore, with a knowledge of the room temperature resistivity of WC (ρ300K ≈ 20 μΩ m) and the temperature coefficient of resistivity α ≈ 4500/K,31 a linear approximation was applied from 300 K to the temperature of interest (1300 K) using the relation ρ = ρ300K (1 + α ΔT). Although strictly, this might be in error, a variation of one order of magnitude in the final result may be expected owing to this approximation. The electrical conductivity (λe = 1/ρ) of a sample with residual porosity, P was calculated as λe(P,T) = λe(0,T) [(1 − P)/(1 + 2P)].29 Using these values, ∇T ≈ 60 × 106 K/m.

Rights and permissions

About this article

Cite this article

Kumar, A.K.N., Subramanian, B. & Kurokawa, K. Defect structure evolution and abnormal grain growth during spark plasma sintering of nano WC–Si powders. Journal of Materials Research 31, 1466–1476 (2016). https://doi.org/10.1557/jmr.2016.130

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.130