Abstract

The fracture behavior of precracked nanocrystals with grain size gradients is simulated using the molecular dynamics method. A large grain size gradient is found to elevate resistance to crack propagation and transform the fracture mode from intergranular to intragranular when the crack is obstructed by a coarse grain. But the intragranular crack is nipped in its bud due to the difficulty of intragranular fracture. However, intergranular fractures can be always kept in nanocrystals with a small grain size gradient. Both the Schmid factors for the slip systems of grains near the crack tip and the critical stress intensity factors are calculated, and energy partitioning is conducted to analyze the mechanisms behind this phenomenon. The research exhibits the key role of grain size gradient in improving the antifracture ability of nanocrystals.

Similar content being viewed by others

References

D. Farkas: Fracture resistance of nanocrystalline Ni. Metall. Mater. Trans. A 38A (13), 2168 (2007).

M.A. Meyers, A. Mishra, and D.J. Benson: Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51 (4), 427 (2006).

T. Zhu and J. Li: Ultra-strength materials. Prog. Mater. Sci. 55 (7), 710 (2010).

Y.M. Wang, M.W. Chen, F.H. Zhou, and E. Ma: High tensile ductility in a nanostructured metal. Nature 419 (6910), 912 (2002).

Y.M. Wang and E. Ma: Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater. 52 (6), 1699 (2004).

I.A. Ovid’Ko and T.G. Langdon: Enhanced ductility of nanocrystalline and ultrafine-grained metals. Rev. Adv. Mater. Sci. 30 (2), 103 (2012).

T.H. Fang, W.L. Li, N.R. Tao, and K. Lu: Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 331 (6024), 1587 (2011).

T. Hanlon, E.D. Tabachnikova, and S. Suresh: Fatigue behavior of nanocrystalline metals and alloys. Int. J. Fatigue 27 (10–12), 1147 (2005).

H.F. Zhou and S.X. Qu: The effect of nanoscale twin boundaries on fracture toughness in nanocrystalline Ni. Nanotechnology 21 (3), 35706 (2010).

H.F. Zhou, S.X. Qu, and W. Yang: Toughening by nano-scaled twin boundaries in nanocrystals. Modell. Simul. Mater. Sci. Eng. 18 (6), 65002 (2010).

Y. Zhang, P.C. Millett, M. Tonks, and S.B. Biner: Deformation twins in nanocrystalline body-centered cubic Mo as predicted by molecular dynamics simulations. Acta Mater. 60 (18), 6421 (2012).

I.A. Ovid Ko and N.V. Skiba: Nanotwins induced by grain boundary deformation processes in nanomaterials. Scr. Mater. 71 (15), 33 (2014).

D. Farkas, H. Van Swygenhoven, and P.M. Derlet: Intergranular fracture in nanocrystalline metals. Phys. Rev. B 66 (6), 60101 (2002).

I.A. Ovid Ko and A.G. Sheinerman: Enhanced ductility of nanomaterials through optimization of grain boundary sliding and diffusion processes. Acta Mater. 57 (7), 2217 (2009).

H.P. Chen, R.K. Kalia, E. Kaxiras, G. Lu, A. Nakano, K. Nomura, A. van Duin, P. Vashishta, and Z.S. Yuan: Embrittlement of metal by solute segregation-induced amorphization. Phys. Rev. Lett. 104 (15), 155502 (2010).

L. Cao and C. Wang: Atomistic simulation for configuration evolution and energetic calculation of crack in body-centered-cubic iron. J. Mater. Res. 21 (10), 2542 (2006).

H. Xie, C. Wang, and T. Yu: Atomistic simulation of fracture in Ni3Al. J. Mater. Res. 23 (6), 1597 (2008).

V. Yamakov, D. Wolf, M. Salazar, S.R. Phillpot, and H. Gleiter: Length-scale effects in the nucleation of extended dislocations in nanocrystalline Al by molecular-dynamics simulation. Acta Mater. 49 (14), 2713 (2001).

D. Chen: Computer model simulation study of nanocrystalline iron. Mater. Sci. Eng., A 190 (1), 193 (1995).

S. Plimpton: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117 (1), 1 (1995).

Y. Mishin, D. Farkas, M.J. Mehl, and D.A. Papaconstantopoulos: Interatomic potentials for monoatomic metals from experimental data and ab initio calculations. Phys. Rev. B 59 (5), 3393 (1999).

D. Faken and H. Jónsson: Systematic analysis of local atomic structure combined with 3D computer graphics. Comput. Mater. Sci. 2 (2), 279 (1994).

A. Stukowski: Visualization and analysis of atomistic simulation data with OVITO—The open visualization tool. Modell. Simul. Mater. Sci. Eng. 18 (1), 15012 (2010).

J. Lu and K. Lu: Surface nanocrystallization (SNC) of materials and its effect on mechanical behavior. In Comprehensive Structural Integrity, I.M.O.R. Karihaloo ed.; Pergamon: Oxford, 2003; p. 495.

J. Xu, X.Z. Mao, Z.H. Xie, and P. Munroe: Damage-tolerant, hard nanocomposite coatings enabled by a hierarchical structure. J. Phys. Chem. C 115 (39), 18977 (2011).

H.Q. Li and F. Ebrahimi: Ductile-to-brittle transition in nanocrystalline metals. Adv. Mater. 17 (16), 1969 (2005).

V. Yamakov, E. Saether, D.R. Phillips, and E.H. Glaessgen: Dynamic instability in intergranular fracture. Phys. Rev. Lett. 95 (1), 15502 (2005).

I.A. Ovid Ko: Review on the fracture processes in nanocrystalline materials. J. Mater. Sci. 42 (5), 1694 (2007).

Y. Zhang, P.C. Millett, M. Tonks, and B. Biner: Deformation-twin-induced grain boundary failure. Scr. Mater. 66 (2), 117 (2012).

V.A. Pozdnyakov and A.M. Glezer: Structural mechanisms of fracture of nanocrystalline materials. Phys. Solid State 47 (5), 817 (2005).

K.S. Kumar, S. Suresh, M.F. Chisholm, J.A. Horton, and P. Wang: Deformation of electrodeposited nanocrystalline nickel. Acta Mater. 51 (2), 387 (2003).

T. Zhou, X. Yang, and C. Chen: Quasicontinuum simulation of single crystal nano-plate with a mixed-mode crack. Int. J. Solids Struct. 46 (9), 1975 (2009).

G.M. Cheng, W.Z. Xu, W.W. Jian, H. Yuan, M.H. Tsai, Y.T. Zhu, Y.F. Zhang, and P.C. Millett: Dislocations with edge components in nanocrystalline bcc Mo. J. Mater. Res. 28 (13), 1820 (2013).

Y.M. Wang, F. Sansoz, T. LaGrange, R.T. Ott, J. Marian, T.W. Barbee, and A.V. Hamza: Defective twin boundaries in nanotwinned metals. Nat. Mater. 12 (8), 697 (2013).

Y.T. Zhu, X.Z. Liao, and X.L. Wu: Deformation twinning in nanocrystalline materials. Prog. Mater. Sci. 57 (1), 1 (2012).

Y. Zhu, Z. Li, and M. Huang: Coupled effect of sample size and grain size in polycrystalline Al nanowires. Scr. Mater. 68 (9), 663 (2013).

I.A. Ovid’Ko, A.G. Sheinerman, and E.C. Aifantis: Effect of cooperative grain boundary sliding and migration on crack growth in nanocrystalline solids. Acta Mater. 59 (12), 5023 (2011).

I.A. Ovid’Ko and A.G. Sheinerman: Nanoscale rotational deformation near crack tips in nanocrystalline solids. J. Phys. D: Appl. Phys. 45 (33), 335301 (2012).

X. Yang, T. Zhou, and C. Chen: Effective elastic modulus and atomic stress concentration of single crystal nano-plate with void. Comput. Mater. Sci. 40 (1), 51 (2007).

J. Zhang and S. Ghosh: Molecular dynamics based study and characterization of deformation mechanisms near a crack in a crystalline material. J. Mech. Phys. Solids 61 (8), 1670 (2013).

T. Shimokawa, M. Tanaka, K. Kinoshita, and K. Higashida: Roles of grain boundaries in improving fracture toughness of ultrafine-grained metals. Phys. Rev. B 83 (21), 214113 (2011).

A. Uhnakova, J. Pokluda, A. Machova, and P. Hora: 3D atomistic simulation of fatigue behaviour of cracked single crystal of bcc iron loaded in mode III. Int. J. Fatigue 33 (12), 1564 (2011).

T. Zhu, J. Li, A. Samanta, A. Leach, and K. Gall: Temperature and strain-rate dependence of surface dislocation nucleation. Phys. Rev. Lett. 100 (2), 025502 (2008).

D.H. Warner, W.A. Curtin, and S. Qu: Rate dependence of crack-tip processes predicts twinning trends in f.c.c. metals. Nat. Mater. 6 (11), 876 (2007).

H.F. Zhou, L.F. Zhang, and S.X. Qu: Temperature effect on critical shear stress for twin boundary migration. Comput. Mater. Sci. 60, 231 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

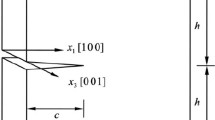

Wang, P., Yang, X. & Tian, X. Fracture behavior of precracked nanocrystalline materials with grain size gradients. Journal of Materials Research 30, 709–716 (2015). https://doi.org/10.1557/jmr.2015.18

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.18