Abstract

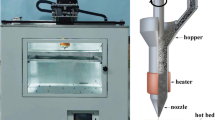

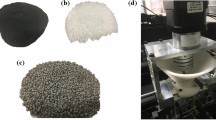

Additive manufacturing (AM) opens new possibilities for functionalization and miniaturization of components in many application fields. Different technologies are known to produce single- or multimaterial components from polymer ceramic or metal. Our new approach — thermoplastic 3D printing — makes it possible to produce metal–ceramic composites. High-filled metal and ceramic suspensions based on thermoplastic binder systems were used as they solidify by cooling. Hence, the portfolio of applicable materials is not limited. Paraffin-based thermoplastic feedstocks with stainless steel powder (17-4PH) and zirconia powder (TZ-3Y-E) were developed with an adapted powder content of 47 vol% steel and 45 vol% zirconia. As compared to other AM technologies, the suspensions were only applied at particular points and areas and not on the whole layer. The printed samples were conventionally debinded and sintered. FESEM studies of the cross-section of the sintered samples showed a homogenous, dense microstructure and a very good connection between the different materials and layers.

Similar content being viewed by others

References

ASTM-Standard F2792-12a: Standard Terminology for Additive Manufacturing Technologies, March 1, 2012, ASTM International Distributed under ASTM license by Beuth publisher.

T. Chartier and A. Badev: Rapid prototyping of ceramics. In Handbook of Advanced Ceramics, S. Somiya ed.; Elsevier, Oxford, UK, 2013; pp. 489–524.

K. Pham-Gia, W. Rossner, B. Wessler, M. Schäfer, and M. Schwarz: Rapid prototyping of high-density alumina ceramics using stereolithography. cfi/Ber. DKG 83, 36–40 (2006).

T. Chartier, C. Duterte, N. Delhote, D. Baillargeat, S. Verdeyme, C. Delage, and C.J. Chaput: Fabrication of millimeter wave components via ceramic stereo- and microstereolithography processes. J. Am. Ceram. Soc. 91, 2469–2474 (2008).

M.L. Griffith and J.W. Halloran: Freeform fabrication of ceramics via stereolithography. J. Am. Ceram. Soc. 79, 2601–2608 (1996).

A. Licciulli, C. Esposito Corcione, A. Greco, V. Amicarelli, and A. Maffezzoli: Laser stereolithography of ZrO2 toughened Al2O3. J. Eur. Ceram. Soc. 25, 1581–1589 (2005).

Y. de Hazan, M. Thanert, M. Trunec, and J. Misak: Robotic deposition of 3d nanocomposite and ceramic fiber architectures via UV curable colloidal inks. J. Eur. Ceram. Soc. 32, 1187–1198 (2012).

R. Felzmann, S. Gruber, G. Mitteramskogler, P. Tesavibul, A.R. Boccaccini, R. Liska, and J. Stampfl: Lithography-based additive manufacturing of cellular ceramic structures. Adv. Eng. Mater. 14, 1052–1058 (2012).

R. Lenk, A. Nagy, H-J. Richter, and A. Techel: Material development for laser sintering of silicon carbide. cfi/Ber. DKG 83, 41–43 (2006).

P. Regenfuss, R. Ebert, and H. Exner: Laser micro sintering — A versatile instrument for the generation of microparts. Laser Tech. J. 4, 26–31 (2007).

Y-C. Hagedorn, J. Wilkes, W. Meiners, K. Wissenbach, and R. Poprawe: Net shaped high performance oxide ceramic parts by selective laser melting. Phys. Procedia 5, 587–594 (2010).

Y. Wu, J. Du, K-L. Choy, and L.L. Hench: Laser densification of alumina powder beds generated using aerosol spray deposition. J. Eur. Ceram. Soc. 27, 4727–4735 (2007).

R.D. Goodridge, J.C. Lorrison, K.W. Dalgarno, and D.J. Wood: Comparison of direct and indirect selective laser sintering of porous apatite mullite glass ceramics. Glass Technol. 45, 94–96 (2004).

U. Gbureck, T. Hoelzel, I. Biermann, J. Barralet, and L.M. Grover: Preparation of tricalcium phosphate/calcium pyrophosphate structures via rapid prototyping. J. Mater. Sci.: Mater. Med. 19, 1559–1563 (2008).

H. Seitz, W. Rieder, S. Irsen, B. Leukers, and C. Tille: Three-dimensional printing of porous ceramic scaffolds for bone tissue engineering. J. Biomed. Mater. Res., Part B 74B, 782–788 (2005).

J.Y.S. Yoon, H. Deyhle, U. Gbureck, E. Vorndran, F. Beckmann, and B. Muller: Three-dimensional morphology and mechanics of bone scaffolds fabricated by rapid prototyping. Int. J. Mater. Res. 103, 200–206 (2012).

A. Khalyfa, W. Meyer, M. Schnabelrauch, S. Vogt, and H-J. Richter: Manufacturing of biocompatible ceramic bone substitutes by 3D-printing. cfi/Ber. DKG 83, 23–26 (2006).

U. Deisinger, F. Irlinger, R. Pelzer, and G. Ziegler: D-printing of HA-scaffolds for the application as bone substitute material. cfi/Ber. DKG 83, 75–78 (2006).

F. Dombrowski, P.W.G. Caso, M.W. Laschke, M. Klein, J. Guenster, and G. Berger: 3-D printed bioactive bone replacement scaffolds of alkaline substituted ortho-phosphates containing meta- and di-phosphates. Key Eng. Mater. 529–530, 138–142 (2013).

A. Zocca, C.M. Gomes, E. Bernardo, R. Muller, J. Gunster, and P. Colombo: LAS glass–ceramic scaffolds by three-dimensional printing. J. Eur. Ceram. Soc. 33, 1525–1533 (2013).

R. Melcher, N. Travitzky, C. Zollfrank, and P. Greil: 3D printing of Al2O3/Cu-O interpenetrating phase composite. J. Mater. Sci. 46, 1203–1210 (2011).

D. Polsakiewicz and W. Kollenberg: Highly loaded alumina inks for use in a piezoelectric print head. Mater. Sci. Eng. Technol. 42, 812–819 (2011).

J. Günster, S. Engler, and J.G. Heinrich: Forming of complex-shaped ceramic products via layer-wise slurry deposition (LSD). Bull. Eur. Ceram. Soc. 1, 25–28 (2003).

B. Cappi, E. Oezkol, J. Ebert, and R. Telle: Direct inkjet printing of Si3N4: Characterization of ink, green bodies, and microstructure. J. Eur. Ceram. Soc. 28, 2625–2628 (2008).

J. Ebert, E. Özkol, A. Zeichner, K. Uibel, Ö. Weiss, U. Koops, R. Telle, and H. Fischer: Direct inkjet printing of dental prostheses made of zirconia. J. Dent. Res. 88, 673–676 (2009).

M. Allahverdi, S.C. Danforth, M. Jafari, and A. Safari: Processing of advanced electroceramic components by fused deposition technique. J. Eur. Ceram. Soc. 21, 1485–1490 (2001).

S. Bose, J. Darsell, H. Hosick, L. Yang, D.K. Sarkar, and A. Bandyopadhyay: Processing and characterization of porous alumina scaffolds. J. Mater. Sci.: Mater. Med. 13, 23–28 (2002).

T. Schlordt, S. Schwanke, F. Keppner, T. Fey, N. Travitzky, and P. Greil: Robocasting of alumina hollow filament lattice structures. J. Eur. Ceram. Soc. 33, 3243–3248 (2013).

J.N. Stuecker, J. Cesarano, III, and D.A. Hirschfeld: Control of the viscous behavior of highly concentrated mullite suspensions for robocasting. J. Mater. Process. Technol. 142, 318–325 (2003).

K. Cai, B. Roman-Manso, J.E. Smay, J. Zhou, M.I. Osendi, M. Belmonte, and P. Miranzo: Geometrically complex silicon carbide structures fabricated by robocasting. J. Am. Ceram. Soc. 95, 2660–2666 (2012).

D. Polsakiewicz and W. Kollenberg: Process and materials development for functionalized printing in three dimensions (FP-3D). refractories WORLDFORUM 4, 1–8 (2012).

F.A. Cetinel, W. Bauer, M. Mueller, R. Knitter, and J. Hausselt: Influence of dispersant, storage time and temperature on the rheological properties of zirconia-paraffin feedstocks for LPIM. J. Eur. Ceram. Soc. 30, 1391–1400 (2010).

L. Gorjan, A. Dakskobler, and T. Kosmac: Strength evolution of injection-molded ceramic parts during wick-debinding. J. Am. Ceram. Soc. 95, 188–193 (2012).

J. Yeo, Y. Jung, and S. Choi: Zirconia-stainless steel functionally graded material by tape casting. J. Eur. Ceram. Soc. 18, 1281–1285 (1998).

M. Dourandish, A. Simchi, E.T. Shabestary, and T. Hartwig: Pressureless sintering of 3Y-TZP/stainless-steel composite layers. J. Am. Ceram. Soc. 91, 3493–3503 (2008).

M. Dourandish and M.A. Simchi: Study the sintering behavior of nanocrystalline 3Y-TZP/430L stainless-steel composite layers for co-powder injection molding. J. Mater. Sci. 44, 1264–1274 (2009).

H-J. Bargel and G. Schulze: In Material Science (original title: Werkstoffkunde), 9th ed. (Springer, Berlin, Heidelberg 2005), pp. 232–334.

A. Bergner, T. Moritz, and A. Michaelis: Steel-ceramic laminates made by tape casting–Processing and interfaces. J. Am. Ceram. Soc. (2014, accepted).

ACKNOWLEDGMENT

The authors would like to thank Mr. Stockmann and Mr. Bedrich for the preparation of the thermoplastic suspensions as well as Mrs. Jungnickel and Mrs. Fischer for the metallographic specimen preparation and the FESEM images.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Scheithauer, U., Bergner, A., Schwarzer, E. et al. Studies on thermoplastic 3D printing of steel–zirconia composites. Journal of Materials Research 29, 1931–1940 (2014). https://doi.org/10.1557/jmr.2014.209

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.209