Abstract

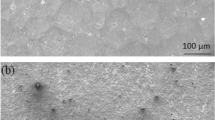

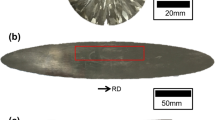

To obtain a nanocrystalline surface layer, 316L stainless steel was treated by fast multiple rotation rolling (FMRR). The microstructure, after FMRR treatment and annealing treatment, was characterized by transmission electron microscopy and x-ray diffraction. Equiaxed nanocrystalline with the average grain size about 12 nm is obtained on the surface layer of FMRR sample. The investigation of thermal stability of the nanocrystalline layer indicates that the grains are still nanocrystalline and the average grain size is about 60 nm for annealing at 500 °C. In addition, the amount of α-martensite increases markedly as the annealing temperature increases from 300 to 500 °C. However, it begins to reduce at 600 °C due to the reversion transformation from martensite to austenite. After annealing at 400 °C, the microhardness of the annealed FMRR sample reaches a maximum value of about 660 HV, and it is four times higher than that of the original sample.

Similar content being viewed by others

References

P. Lacombe, B. Baroux, and G. Beranger: les aciers inoxydables, les editions de physiques (les Ulis cedex A, France, 1990), p. 663.

E.O. Hall: The deformation and ageing of mild steel: III. Discussion of results. Proc. Phys. Soc. London, Sect. B 64, 747–753 (1951).

N.J. Petch: The cleavage strength of polycrystals. J. Iron Steel Inst. 174, 25–28 (1953).

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov: Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 45, 103–189 (2000).

R.Z. Valiev, A.V. Korznikov, and R.R. Mulyukov: Structure and properties of ultrafine-grained materials produced by severe plastic deformation. Mater. Sci. Eng., A 168, 141–148 (1993).

K.H. Song, H.S. Kim, and W.Y. Kim: Improvement of mechanical properties in severely plastically deformed Ni–Cr alloy. Mater. Des. 35, 685–690 (2012).

B. Radiguet, A. Etienne, P. Pareige, X. Sauvage, and R. Valiev: Irradiation behavior of nanostructured 316 austenitic stainless steel. J. Mater. Sci. 43, 7338–7343 (2008).

Y. Mine, Z. Horita, and Y. Murakami: Effect of hydrogen on martensite formation in austenitic stainless steels in high-pressure torsion. Acta Mater. 57, 2993–2002 (2009).

J. Čížek, I. Procházka, O. Melikhova, G. Brauer, W. Anwand, R. Kužel, M. Cieslar, and R.K. Lslamgaliev: Investigation of spatial distribution of defects in ultra-fine grained copper. Appl. Surf. Sci. 194, 140–144 (2002).

Y. Todaka, M. Umemoto, J. Yin, Z.G. Liu, and K. Tsuchiya: Role of strain gradient on grain refinement by severe plastic deformation. Mater. Sci. Eng., A 462, 264–268 (2007).

R.Z. Valiev, A.V. Sergueeva, and A.K. Mukherjee: The effect of annealing on tensile deformation behavior of nanostructured SPD titanium. Scr. Mater. 49, 669–674 (2003).

A. Balyanov, J. Kutnyakova, N.A. Amirkhanova, V.V. Stolyarov, R.Z. Valiev, X.Z. Liao, Y.H. Zhao, Y.B. Jiang, H.F. Xu, T.C. Lowe, and Y.T. Zhu: Corrosion resistance of ultra fine-grained Ti. Scr. Mater. 51, 225–229 (2004).

Y.T. Zhu, J.Y. Huang, J. Gubicza, T. Ungár, Y.M. Wang, E. Ma, and R.Z. Valiev: Nanostructures in Ti processed by severe plastic deformation. J. Mater. Res. 18, 1908–1917 (2003).

V.V. Stolyarov, Y.T. Zhu, I.V. Alexandrov, T.C. Lowe, and R.Z. Valiev: Grain refinement and properties of pure Ti processed by warm ECAP and cold rolling. Mater. Sci. Eng., A 343, 43–50 (2003).

V.V. Stolyarov, Y.T. Zhu, T.C. Lowe, and R.Z. Valiev: Microstructure and properties of pure Ti processed by ECAP and cold extrusion. Mater. Sci. Eng., A 303, 82–89 (2001).

H. Ueno, K. Kakihata, Y. Kaneko, S. Hashimoto, and A. Vinogradov: Enhanced fatigue properties of nanostructured austenitic SUS 316L stainless steel. Acta Mater. 59, 7060–7069 (2011).

K. Oh-ishia, Z.J. Horita, D.J. Smith, and T.G. Langdon: Grain boundary structure in Al–Mg and Al–Mg–Sc alloys after equal-channel angular pressing. J. Mater. Res. 16, 583–589 (2001).

X.N. Du, S.M. Yin, S.C. Liu, B.Q. Wang, and J.D. Guo: Effect of the electropulsing on mechanical properties and microstructure of an ECAPed AZ31 Mg alloy. J. Mater. Res. 23, 1570–1577 (2008).

H.S. Kim: Evaluation of strain rate during equal-channel angular pressing. J. Mater. Res. 17, 172–179 (2002).

Y. Li, L. Wang, D.D. Zhang, and L. Shen: The effect of surface nanocrystallization on plasma nitriding behaviour of AISI 4140 steel. Appl. Surf. Sci. 257, 979–984 (2010).

Y.J. Mai, X.H. Jie, L.L. Liu, N. Yu, and X.X. Zheng: Thermal stability of nanocrystalline layers fabricated by surface nanocrystallization. Appl. Surf. Sci. 256, 1972–1975 (2010).

D. Li, H.N. Chen, and H. Xu: The effect of nanostructured surface layer on the fatigue behaviors of a carbon steel. Appl. Surf. Sci. 255, 3811–3816 (2009).

Z.B. Wang, J. Lu, and K. Lu: Investigations on composition and morphology of electrochemical conversion layer/titanium dioxide deposit on stainless steel. Surf. Coat. Technol. 201, 2796–2801 (2006).

P.F. Chui, K.N. Sun, C. Sun, X.Q. Yang, and T. Shan: Effect of surface nanocrystallization induced by fast multiple rotation rolling on hardness and corrosion behavior of 316L stainless steel. Appl. Surf. Sci. 257, 6787–6791 (2011).

X.H. Chen, J. Lu, L. Lu, and K. Lu: Tensile properties of a nanocrystalline 316L austenitic stainless steel. Scr. Mater. 52, 1039–1044 (2005).

W.P. Tong, Z. Han, L.M. Wang, J. Lu, and K. Lu: Low-temperature nitriding of 38CrMoAl steel with a nanostructured surface layer induced by surface mechanical attrition treatment. Surf. Coat. Technol. 202, 4957–4963 (2008).

V. Tsakiris and D.V. Edmonds: Martensite and deformation twinning in austenitic steels. Mater. Sci. Eng., A 273–275, 430–436 (1999).

P. Peyre, X. Scherpereel, L. Berthe, C. Carboni, R. Fabbro, G. Beranger, and C. Lemaitre: Surface modifications induced in 316L steel by laser peening and shot-peening. Influence on pitting corrosion resistance. Mater. Sci. Eng., A 280, 294–302 (2000).

K. Rajanna, B. Pathiraj, and B.H. Kolster: X-ray fractography studies on austenitic stainless steels. Eng. Fract. Mech. 54, 155–166 (1996).

B. Fultz and J.M. Howe: Transmission Electron Microscopy and Diffractometry of Materials, 2nd ed. (Springer, Berlin, Germany, 2002).

H.P. Klug and L.E. Alexander: X-Ray Diffraction Procedures for Polycrystalline and Amorphous Materials, 2nd ed. (Wiley, New York, 1974), p. 661.

T.S. Wang, J.K. Yu, and B.F. Dong: Surface nanocrystallization induced by shot peening and its effect on corrosion resistance of 1Cr18Ni9Ti stainless steel. Surf. Coat. Technol. 200, 4777–4781 (2006).

T. Roland, D. Retraint, K. Lu, and J. Lu: Enhanced mechanical behavior of a nanocrystallised stainless steel and its thermal stability. Mater. Sci. Eng., A 445–446, 281–288 (2007).

A. Etienne, B. Radiguet, C. Genevois, J-M. Le Breton, R. Valiev, and P. Pareige: Thermal stability of ultrafine-grained austenitic stainless steels. Mater. Sci. Eng., A 527, 5805–5810 (2010).

Y. Zhang, X.T. Jing, B.Z. Lou, F.S. Shen, and F.Z. Cui: Mechanism and reversible behavior of the α′ → γ transformation in 1Cr18Ni9Ti stainless steel. J. Mater. Sci. 34, 3291–3296 (1999).

A. Di Schino, I. Salvatori, and J.M. Kenny: Effects of martensite formation and austenite reversion on grain refining of AISI 304 stainless steel. J. Mater. Sci. 37, 4561–4565 (2002).

ACKNOWLEDGMENTS

This work was supported by the Natural Science Foundation of the People’s Republic of China (no. 30870610, 30800221), China Postdoctoral Science Foundation (no. 200804401138), and Research Fund for Doctoral Program of Shaanxi University of Technology (no. SLGQD13 (2)-14).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chui, P., Sun, K. Thermal stability of a nanostructured layer on the surface of 316L stainless steel. Journal of Materials Research 29, 556–560 (2014). https://doi.org/10.1557/jmr.2014.16

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.16