Abstract

Pure platinum was probed with a nanoindenter fitted with a Berkovich tip to various depths. The indent pattern was made on the as-polished specimen prior to heat treating, after heat treating at 500 °C for 30 min, and again after further heat treating at 1000 °C for 30 min. The variability in the measured hardness decreased as the indentation depth increased from 50 to 300 nm. When the sampled was annealed, the hardness variation was also greater. Increasing hardness variation with decreasing dislocation density and sampling volume indicates that dislocation density plays a critical role in the observed variation, beyond solely instrumentation uncertainty, and supports a defect-based explanation for the stochastic behavior. It appears that the stochastic behavior occurs when multiple dislocations are present in the sampled volume rather than sampling only a single dislocation.

Similar content being viewed by others

References

D.M. Tanner, T.B. Parson, A.D. Corwin, J.A. Walraven, J.W. Wittwer, B.L. Boyce, and S.R. Winzer: Science-based MEMS reliability methodology. Microelectron. Reliab. 47, 1806 (2007).

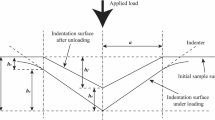

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1564 (1992).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19(1), 3 (2004).

M.F. Doerner and W.D. Nix: A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1(4), 601 (1986).

A.C. Fischer-Cripps: Nanoindentation (Springer, New York, 2002).

S.N. Dub, Y.Y. Lim, and M.M Chaudhri: Nanohardness of high purity Cu (111) single crystals: The effect of indenter load and prior plastic sample strain. J. Appl. Phys. 107, 043510 (2010).

T.S. Srivatsan, B.G. Ravi, A.S. Naruka, L Riester, S. Yoo, and T.S. Sudarshan: A study of microstructure and hardness of bulk copper sample obtained by consolidating nanocrystalline powders using plasma pressure compaction. Mater. Sci. Eng., A 311, 22 (2001).

Y. Chen and I.W. Hunter: Stochastic system identification of skin properties: Linear and wiener static nonlinear methods. Ann. Biomed. Eng. 40, 2242 (2012).

A.L. Romasco, L.H. Friedman, L. Fang, R.A. Meirom, T.E. Clark, R.G. Polcawich, J.S. Pulskamp, M. Dubey, and C.L. Muhlstein: Deformation behavior of nanograined platinum films. Thin Solid Films 518, 3866 (2010).

H. Lee, R.A. Coutu, S. Mall, and K.D. Leedy: Characterization of metal and metal alloy films as contact materials in MEMS switches. J. Micromech. Microeng. 16, 557 (2006).

D.T. Read, R.R. Keller, N. Barbosa, and N. Geiss: Nanoindentation round robin on thin film copper on silicon. Metall. Mater. Trans. A 38, 2242 (2007).

J.C. Hay, A. Bolshakov, and G.M. Pharr: A critical examination of the fundamental relations used in the analysis of nanoindentation data. J. Mater. Res. 14(6), 2296 (1999).

X.D. Hou, A.J. Bushby, and N.M. Jennett: Direct measurement of surface shape for validation of indentation deformation and plasticity length-scale effects: A comparison of methods. Meas. Sci. Technol. 21, 115015 (2010).

M.S. Bobji, S.K. Biswas, and J.B. Pethica: Effect of roughness on the measurement of nanohardness: A computer simulation study. Appl. Phys. Lett. 71(8), 1059 (1997).

W.W. Gerberich, W. Yu, D. Kramer, A. Strojny, D. Bahr, E. Lilleodden, and J. Nelson: Elastic loading and elastoplastic unloading from nanometer level indentations for modulus determinations. J. Mater. Res. 13(2), 421 (1998).

A.C. Fischer-Cripps: Critical review of analysis and interpretation of nanoindentation test data. Surf. Coat. Technol. 200(14–15), 4153 (2005).

A.A. Zbib and D.F. Bahr: Dislocation nucleation and source activation during nanoindentation yield points. Metall. Mater. Trans. A 37, 2249 (2007).

P. Trtik, B. Munch, and P. Lura: A critical examination of statistical nanoindentation on model materials and hardened cement pastes based on virtual experiments. Cem. Concr. Compos. 31, 705 (2009).

W.M. Mook, C. Niederberger, M. Bechelany, L. Philippe, and J. Michler: Compression of freestanding gold nanostructures: From stochastic yield to predictable flow. Nanotechnology 21, 055701 (2010).

K.S. Ng and A.H.W. Ngan: Stochastic nature of plasticity of aluminum micro-pillars. Acta Mater. 56, 1712 (2008).

J.R. Morris, H. Bei, G.M. Pharr, and E.P. George: Size effects and stochastic behavior of nanoindentation pop in. Phys. Rev. Lett. 106, 165502 (2001).

C.A. Schuh, J.K. Mason, and A.C. Lund: Quantitative insight into dislocation nucleation from high-temperature nanoindentation experiments. Nat. Mater. 4, 617–621 (2005).

M.M. Biener, J. Biener, A.M. Hodge, and A.V. Hamza: Dislocation nucleation in bcc Ta single crystals studied by nanoindentation. Phys. Rev. B. 76, 165422 (2007).

I. Salehinia and D.F. Bahr: The impact of a variety of point defects on the inception of plastic deformation in dislocation-free metals. Scr. Mater. 66, 339 (2012).

I. Salehinia, V. Perez, and D.F. Bahr: Effect of vacancies on incipient plasticity during contact loading. Philos. Mag. 92(5), 550 (2012).

I. Salehinia and S.N. Medyanik: Effects of vacancies on the onset of plasticity in metals: An atomistic simulation study. Metall. Mater. Trans. A 42, 3868 (2011).

A. Barnoush: Correlation between dislocation density and nanomechanical response during nanoindentation. Acta Mater. 60, 1268 (2012).

B. Zhang, W. Wang, and G.P. Zhang: Depth dependent hardness variation in Ni–P amorphous film under nanoindentation. Mater. Sci. Technol. 22(6), 734 (2006).

G. Farges and D. Degout: Interpretation of the indentation size effect in vickers microhardness measurements-absolute hardness of materials. Thin Solid Films 181, 365 (1989).

K. Durst, O. Franke, A. Böhner, and M. Göken: Indentation size effect in Ni–Fe solid solutions. Acta Mater. 55, 6825 (2007).

G.M. Pharr, E.G. Herbert, and Y. Gao: The indentation size effect: Critical examination of experimental observations and mechanistic interpretations. Annu. Rev. Mater. Res. 40, 271 (2010).

A.A. Elmustafa, J.A. Eastman, M.N. Rittner, J.R. Weertman, and D.S. Stone: Indentation size effect: Large grained aluminum versus nanocrystalline aluminum-zirconium alloys. Scr. Mater. 43, 951 (2000).

Y.Y. Lim and M.M. Chaudhri: The influence of grain size on the indentation hardness of high-purity copper and aluminium. Philos. Mag. 82(10), 2071 (2002).

International Standard ISO 14577-2: Metallic Materials–Instrumented Indentation Test for Hardness and Materials Parameters–Part 2: Verification and Calibration of Testing Machines, 1st ed., ISO, 2002.

B.D. Craig and D.S. Anderson: Handbook of Corrosion Data, 2nd ed. (A.S.M. International, Materials Park, OH, 2002), pp. 76–77.

A.R. Powell: Behavior of the platinum metals at high temperatures. Platinum Met. Rev. 2(3), 95 (1958).

International Standard ISO 14577-1: Metallic Materials–Instrumented Indentation Test for Hardness and Materials Parameters–Part 1: Test Method, 1st ed., ISO, 2002.

D.F. Bahr and D.J. Morris: Nanoindentation: Localized probes of mechanical behavior of materials. In Springer Handbook of Experimental Solid Mechanics, edited by W.N. Sharpe (Springer, New York, 2008), pp. 389–408.

S. Harvey, H. Huang, S. Venkataraman, and W.W. Gerberich: Microscopy and microindentation mechanics of single crystal Fe-3 wt.% Si: Part I. Atomic force microscopy of a small indentation. J. Mater. Res. 8(6), 1291 (1993).

M.J. Cordill, N.R. Moody, and W.W. Gerberich: Effects of dynamic indentation on the mechanical response of materials. J. Mater. Res. 23(6), 1604 (2008).

G.M. Pharr, J.H. Strader, and W.C. Oliver: Critical issues in making small-depth mechanical property measurements by nanoindentation with continuous stiffness measurement. J. Mater. Res. 24(3), 653 (2009).

M.J. Cordill, M.S. Lund, J. Parker, C. Leighton, A.K. Nair, D. Farkas, N.R. Moody, and W.W. Gerberich: The nano-jackhammer effect in probing near-surface mechanical properties. Int. J. Plast. 25, 2045 (2009).

K.W. Sui and A.H.W. Ngan: The continuous stiffness measurement technique in nanoindentation intrinsically modifies the strength of the sample. Philos. Mag. 93(5), 449 (2013).

G. Van Belle and D.C. Martin: Sample size as a function of coefficient of variation and ratio of means. The American Statistician 47(3), 165 (1993).

W.D. Nix and H. GaoIndentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 46(3), 411 (1997).

W.W. Gerberich, N.I. Tyamiak, J.C. Grunlan, M.F. Horstemeyer, and M.I. Baskes: Interpretations of indentation size effects. J. Appl. Mech. 69, 433 (2002).

K. Danas, V.S. Deshpande, and N.A. Fleck: Size effects in the conical indentation of an elasto-plastic solid. J. Mech. Phys. Solids 60, 1605 (2012).

L. Ma, D.J. Morris, S.L. Jennerjohn, D.F. Bahr, and L. Levine: Finite element analysis and experimental investigation of the Hertzian assumption on the characterization of initial plastic yield. J. Mater. Res. 24, 1059–1068 (2009).

J.J. Voost and W.D. Nix: Indentation modulus of elastically anisotropic half spaces. Philos. Mag. A 76(5), 1045 (1993).

V. Bhakhri and R.J. Klassen: The depth dependence of the indentation creep of polycrystalline gold at 300 K. Scr. Mater. 55, 395 (2006).

S.A. Syed Asif and J.B. Pethica: Nanoindentation creep of single-crystal tungsten and gallium arsenide. Philos. Mag. 76(6), 1105 (1997).

D.M. Norfleet, D.M. Dimiduk, S.J. Polasik, M.D. Uchic, and M.J. Mills: Dislocation structures and their relationship to strength in deformed nickel microcrystals. Acta Mater. 56, 2988 (2008).

A.S. Schneider, D. Kiener, C.M. Yakacki, H.J. Maier, P.A. Gruber, N. Tamura, M. Kunz, A.M. Minor, and C.P. Frick: Influence of bulk pre-straining on the size effect in nickel compression pillars. Mater. Sci. Eng., A 559, 147 (2013).

S. Shao, N. Abdolrahim, D.F. Bahr, G. Lin, and H.M. Zbib: Stochastic effects in plasticity in small volumes. Int. J. Plast. (2013, accepted). DOI: 10.1016/j.ijplas.2013.09.005

C.P. Frick, B.G. Clark, S. Orso, A.S. Schneider, and E. Arzt: Size effect of strength and strain hardening of small-scale [111] nickel compression pillars. Mater. Sci. Eng., A 489, 319 (2008).

C.A. Volkert and E.T. Lilleodden: Size effects in the deformation of sub-micron Au columns. Philos. Mag. 86, 5567 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Address all correspondence to this author.

Supplementary Material

Supplementary Material

Supplementary materials can be viewed in this issue of the Journal of Materials Research by visiting http://journals.cambridge.org/jmr.

Rights and permissions

About this article

Cite this article

Maughan, M.R., Zbib, H.M. & Bahr, D.F. Variation in the nanoindentation hardness of platinum. Journal of Materials Research 28, 2819–2828 (2013). https://doi.org/10.1557/jmr.2013.285

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.285