Abstract

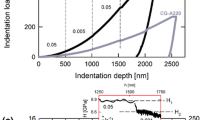

The capability for high temperature nanoindentation measurements to 950 °C in high vacuum has been demonstrated on polycrystalline tungsten, a material of great importance for nuclear fusion and spallation applications and as a potential high temperature nanomechanics reference sample. It was possible to produce measurements with minimal thermal drift (typically ~0.05 nm/s at 750–950 °C) and no visible oxidative damage. The temperature dependence of the hardness, elastic modulus, plasticity index, creep, creep strain, and creep recovery were investigated over the temperature range, testing at 25, 750, 800, 850, 900 and 950 °C. The nanoindentation hardness measurements were found to be consistent with previous determinations by hot microhardness. Above 800 °C the hardness changes relatively little but more pronounced time-dependent deformation and plasticity were observed from 850 °C. Plasticity index, indentation creep and creep recovery all increase with temperature. The importance of increased time-dependent deformation and pile-up on the accuracy of the elastic modulus measurements are discussed. Elastic modulus measurements determined from elastic analysis of the unloading curves at 750–800 °C are close to literature bulk values (to within ~11 %). The high temperature modulus measurements deviate more from bulk values determined taking account of the high temperature properties of the indenter material at the point (850 °C) at which more significant time-dependent deformation is observed. This is thought to be due to the dual influence of increased time-dependency and pile-up that are not being accounted for in the elastic unloading analysis. Accounting for this time-dependency by applying a viscoelastic compliance correction developed by G. Feng and A.H.W. Ngan (J. Mater. Res. (2002) 17:660–668) greatly reduces the values of the elastic modulus, so they are agree to within 6 % of literature values at 950 °C.

Similar content being viewed by others

References

Wheeler JM, Armstrong DEJ, Heinz W, Schwaiger R (2015) High temperature nanoindentation: the state of the art and future challenges. Curr Opin Solid State Mater Sci 19:354–366

Beake BD, Fox-Rabinovich GS (2014) Progress in high temperature nanomechanical testing of coatings for optimising their performance in high speed machining. Surf Coat Technol 255:102–111

Korte SK, Stearn RJ, Wheeler JM, Clegg WJ (2012) High temperature microcompression and nanoindentation in vacuum. J Mater Res 27:167–176

Wheeler JM, Michler J (2013) Invited article: indenter materials for high temperature nanoindentation. Rev Sci Instrum 84:101301

Vandeperre LJ, Giuliani F, Lloyd SJ, Clegg WJ (2007) The hardness of silicon and germanium. Acta Mater 55:6307–6315

Domnich V, Aratyn Y, Kriven WM, Gogotsi Y (2008) Temperature dependence of silicon hardness: experimental evidence of phase transformation. Rev Adv Mater Sci 17:33–41

Nieh TG, Iwamoto C, Ikuhara Y, Lee KW, Chung YW (2004) Comparative studies of crystallization of a bulk Zr–Al–Ti–Cu–Ni amorphous alloy. Intermetallics 12:1183–1189

Korte SK, Clegg WJ (2009) Micropillar compression of ceramics at elevated temperature. Scr Mater 60:807–810

Bhakhri V, Klassen RJ (2006) Investigation of high-temperature plastic deformation using instrumented microindentation tests. Part I The deformation of three aluminium alloys at 473 K to 833 K. J Mater Sci 41:2259–2270

Korte SK, Banard JS, Stearn RJ, Clegg WJ (2011) Deformation of silicon, insights from microcompression testing at 25–500 °C. Int J Plast 27:1853–1866

Trenkle JC, Packard CE, Schuh CA (2010) Hot nanoindentation in inert environments. Rev Sci Instrum 81:073901

Beake BD, Smith JF (2002) High-temperature nanoindentation testing of fused silica and other materials. Philos Mag A 82:2179–2186

Everitt NM, Davies MI, Smith JF (2011) High temperature nanoindentation - the importance of isothermal contact. Philos Mag 91:1221–1244

Pearson SR, Shipway PH, Abere JO, Hewitt RAA (2013) The effect of temperature on wear and friction of a high strength steel in fretting. Wear 303:622

Huang Z, Harris AJ, Maloy SA, Hosemann P (2014) Nanoindentation creep study on an ion beam irradiated ODS alloy. J Nucl Mater 451:162–167

Harris AJ, Beake BD, Armstrong DEJ (2015) Extreme nanomechanics: vacuum nanoindentation and nanotribology to 950 °C. Tribology 9:174–180

Fox-Rabinovich GS, Beake BD, Veldhuis SC, Endrino JL, Parkinson R, Shuster LS, Migranov MS (2006) Impact of mechanical properties measured at room and elevated temperatures on wear resistance of cutting tools with TiAlN and AlCrN coatings. Surf Coat Technol 200:5738–5742

Beake BD, Fox-Rabinovich GS, Veldhuis SC, Goodes SR (2009) Coating optimisation for high-speed machining with advanced nanomechanical test methods. Surf Coat Technol 203:1919–1925

Fox-Rabinovich GS, Endrino JL, Agguire MH, Beake BD, Veldhuis SC et al (2012) Mechanism of adaptability for the nano-structured TiAlCrSiYN-based hard physical vapor deposition coatings under extreme frictional conditions. J Appl Phys 111:064306

Beake BD, Fox-Rabinovich GS, Losset Y, Yamamoto K et al (2012) Why can TiAlCrSiYN-based adaptive coatings deliver exceptional performance under extreme frictional conditions? Faraday Discuss 156:267–278

Rebelo de Figueiredo M, Abad MD, Harris AJ, Czettl C, Mitterer C, Hosemann P (2015) Nanoindentation of chemical-vapor deposited Al2O3 hard coatings at elevated temperatures. Thin Solid Films 578:20–24

Gibson JSK-L, Roberts SG, Armstrong DEJ (2015) High-temperature indentation of helium-implanted tungsten. Mater Sci Eng A 625:380–384

Sawant A, Tin S (2008) High temperature nanoindentation of a Re-bearing single crystal Ni-base superalloy. Scr Mater 58:275–278

Sawant A, Tin S, Zhao J-C (2008) High temperature nanoindentation of Ni-base superalloys. In: Reed RC, Green KA, Caron P, Gabb TP, Fahrmann EG, Huron ES, Woodard SA (eds) Superalloys 2008. TMS, 863–871

Milhans J, Li DS, Khaleel M, Sun MX, Al-Haik MS, Harris AJ, Garmestani H (2011) Mechanical properties of solid oxide fuel cell glass-ceramic seal at high Temperatures. J Power Sources 196:5599–5603

Armstrong DEJ, Tarleton E (2015) Bend testing of silicon microcantilevers from 21 °C to 770 °C. JOM 67:2914–2920

Everitt NM (1992) Indentation creep on single crystal magnesium oxide. J Hard Mater 3:269–284

ISO 14577: Metallic materials—instrumented indentation test for hardness and materials parameters, parts 1–4

Determination of the hardness and modulus of thin films and coatings (INDICOAT), Jennett NM et al., NPL Report MATC(A) Mat 24, 2001, ISSN 1473–2734. EU-funded project SMT4-CT98-2249

Jennett NM, Bushby AJ (2002) Adaptive protocol for robust estimates of coatings properties by nanoindentation. Mater Res Soc Symp Proc 695:73–78

Chudoba T, Richter F (2001) Investigation of creep behaviour under load during indentation experiments and its influence on hardness and modulus results. Surf Coat Technol 148:191–198

Feng G, Ngan AHW (2002) Effects of creep and thermal drift on modulus measurement using depth-sensing indentation. J Mater Res 17:660–668

Chen J, Shen Y, Liu W, Beake BD, Shi X, Wang Z, Zhang Y, Gu X (2016) Effects of loading rate on development of pile-up during indentation creep of polycrystalline copper. Mater Sci Eng A 656:216–221

Lofaj F, Kaganovskii YS (1995) Kinetics of WC-Co oxidation accompanied by swelling. J Mater Sci 30:1811–1817

Kermouche G, Barthel E, Vamdembroucq D, Dubujet P (2008) Mechanical modelling of indentation induced densification in amorphous silica. Acta Mater 56:3222–3228

Chudoba T, Jennett NM (2008) Higher accuracy analysis of instrumented indentation data obtained with pointed indenters. J Phys D Appl Phys 41:215407

Michel MD, Serbena FC, Lepienski CM (2006) Effect of temperature on hardness and indentation cracking of fused silica. J Non-Cryst Solids 352:3550–3555

Gross TM, Tomozawa M (2008) Crack-free high load Vickers indentation of silica glass. J Non-Cryst Solids 354:5567–5569

Morris DJ, Myers SG, Cook RF (2004) Sharp probes of varying acuity: instrumented indentation and fracture behaviour. J Mater Res 19:165–175

Lassner E, Schubert WD (1999) Tungsten: properties, chemistry, technology of the element, alloys and chemical compounds. Kluwer, New York

Lozinskii MG (1961) High temperature metallography. Pergamon Press, Oxford

Milman YV (2008) Plasticity characteristic obtained by indentation. J Phys D Appl Phys 41:074013 (9pp)

Milman YV, Galanov BA, Chugunova SI (1993) Plasticity characteristic obtained through hardness measurement. Acta Metall Mater 41:2523–2532

Milman YV (1985) Structural aspects of warm and cold plastic deformation of crystalline materials. Metal Sci Heat Treat 27:397–402 (translated from Metallovedenie i Termicheskaya Obrabotka Metallov 6 (1985) 2–6)

Savoini B, Martinez J, Munoz A, Monge MA, Pareja R (2013) Microstructure and temperature dependence of the microhardness of W-4 V-1La2O3 and W-Ti-1La2O3. J Nucl Mater 442:S229–S232

Simmons G, Wang H (1971) Single crystal constants and calculated aggregate properties: a handbook, 2nd edn. MIT Press, Cambridge

Tanno T, Fukuda M, Nogami S, Hasegawa A (2011) Microstructure development in neutron irradiated tungsten alloys. Mater Trans 52:1447–1451

Cheng YT, Cheng CM (1998) Relationships between hardness, elastic modulus, and the work of indentation. Appl Phys Lett 73:614–616

Cheng YT, Cheng CM (2004) Scaling, dimensional analysis, and indentation measurements. Mater Sci Eng R 44:91–149

Tang F, Zhang LC (2011) On the reliability of nanoindentation on Si wafer at elevated temperatures. Adv Mater Res 325:684–689

Beake BD (2006) Modelling indentation creep of polymers: a phenomenological approach. J Phys D Appl Phys 39:4478–4485

Chen J, Beake BD, Bell GA, Tait Y, Gao F (2015) Probing polymer chain constraint and synergistic effects in nylon 6-clay nanocomposites and nylon 6-silica flake sub-micro composites with nanomechanics. Nanocomposites 1:185–194

Beake BD, Harris AJ, Liskiewicz TW (2015) Advanced nanomechanical techniques, chapter 1. In: Ranganathan N (ed) Materials characterization: modern methods and applications. Pan Stanford Press, Singapore, pp 1–90

Aguado F, Baonza VG (2006) Prediction of bulk modulus at high temperatures from longitudinal phonon frequencies: application to diamond, c-BN and 3C-SiC. Phys Rev B 73:024111

Davies MI (2013) High temperature nanoindentation characterisation of P91 and P92 Steel. PhD Thesis, University of Nottingham

Oliver WC, Pharr GM (1992) An improved technique for measuring hardness and elastic modulus through load and displacement sensing indentation experiments. J Mater Res 7:1564

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J Mater Res 19:3–20

Lee YH, Hahn JH, Nahm SH, Jang JI, Kwon D (2008) Investigations on indentation size effects using a pile-up corrected hardness. J Phys D Appl Phys 41:074027 (5 pp)

Lee YH, Baek U, Kim YI, Nahm SH (2007) On the measurement of pile-up corrected hardness based on the early Hertzian loading analysis. Mater Lett 61:4039–4042

Stelmashenko NA, Walls MG, Brown LM, Milman YV (1993) Microindentations on W and Mo oriented single crystals: an STM study. Acta Metall Mater 41:2855–2865

Bolshakov A, Pharr GM (1998) Influence of pileup on the measurement of mechanical properties by load and depth sensing indentation techniques. J Mater Res 13:1049–1058

Gale JD, Achuthan A (2014) The effect of work-hardening and pile-up on nanoindentation measurements. J Mater Sci 49:5066–5075

Beake BD, Goodes SR, Smith JF, Fox-Rabinovich GS, Veldhuis SC (2010) Using nanomechanics to optimise coatings for cutting tools. In Zhang S (ed) Handbook of nanostructured thin films and coatings, mechanical properties. CRC Press, pp 205–244

Beake BD, Liskiewicz TW, Vishnyakov VM, Davies MI (2015) Development of DLC coating architectures for demanding functional surface applications through nano- and micro-mechanical testing. Surf Coat Technol 284:334–343

Choi Y, Lee HS, Kwon D (2004) Analysis of sharp-tip indentation load-depth curve for contact area determination taking into account pile-up and sink-in effects. J Mater Res 19:3307–3315

Park C-P, Lee J-L, Kang S-K, Kim Y-C, Woo K-S, Jeon S-W, Kwon D (2016) Evaluation of high-temperature Vickers hardness using instrumented indentation system. Mater Sci Eng A 650:15–19

Acknowledgments

DEJA acknowledges The Royal Academy of Engineering for a Research Fellowship at the University of Oxford and the Culham Centre for Fusion Energy for funding via a Research Fellowship at St Edmund Hall, Oxford.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Harris, A.J., Beake, B.D., Armstrong, D.E.J. et al. Development of High Temperature Nanoindentation Methodology and its Application in the Nanoindentation of Polycrystalline Tungsten in Vacuum to 950 °C. Exp Mech 57, 1115–1126 (2017). https://doi.org/10.1007/s11340-016-0209-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-016-0209-3