Abstract

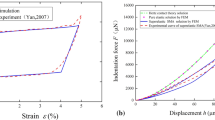

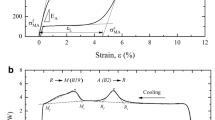

An experimental study on the indentation hardness of NiTi shape memory alloys (SMAs) by using a spherical indenter tip and a finite element investigation to understand the experimental results are presented in this paper. It is shown that the spherical indentation hardness of NiTi SMAs increases with the indentation depth. The finding is contrary to the recent study on the hardness of NiTi SMAs using a sharp Berkovich indenter tip, where the interfacial energy plays a dominant role at small indentation depths. Our numerical investigation indicates that the influence of the interfacial energy is not significant on the spherical indentation hardness of SMAs. Furthermore, the depth dependency of SMA hardness under a spherical indenter is explained by the elastic spherical contact theory incorporating the deformation effect of phase transformation of SMAs. Hertz theory for purely elastic contact shows that the spherical hardness increases with the square root of the indentation depth. The phase transformation beneath the spherical tip weakens the depth effect of a purely elastic spherical hardness. This study enriches our knowledge on the basic concept of hardness for SMAs under spherical indentation at micro- and nanoscales.

Similar content being viewed by others

References

J.F. Archard: Contact and rubbing of flat surfaces. J. Appl. Phys. 24, 981 (1953).

D. Tabor: The Hardness of Metals, 1st ed. (Oxford Press, London, England, 1951), p. 85.

Y.T. Cheng and C.M. Cheng: What is indentation hardness?Surf. Coat. Technol. 133-134, 417 (2000).

Y.T. Cheng and C.M. Cheng: Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng., R. 44, 91 (2004).

Q. Ma and D.R. Clarke: Size dependent hardness of silver single crystals. J. Mater. Res. 10, 853 (1995).

K.W. McElhaney, J.J. Vlassk, and W.D. Nix: Determination of indenter tip geometry and indentation contact area for depth sensing indentation experiments. J. Mater. Res. 13, 1300 (1998).

W.D. Nix and H. Gao: Indentation size effects in crystalline materials: A law of strain gradient plasticity. J. Mech. Phys. Solids 46, 411 (1998).

Y. Huang, F. Zhang, K.C. Hwang, W.D. Nix, G.M. Pharr, and G. Feng: A model of size effects in nano-indentation. J. Mech. Phys. Solids 54, 1668 (2006).

J.G. Swadener, E.P. George, and G.M. Pharr: The correlation of the indentation size effect measured with indenters of various shapes. J. Mech. Phys. Solids 50, 681 (2002).

G.A. Shaw, J.S. Trethewey, A.D. Johnson, W.J. Drugan, and W.C. Crone: Thermomechanical high-density data storage in a metallic material via the shape-memory effect. Adv. Mater. 17, 1123 (2005).

G. Satoh, A. Birnbaum, and Y.L. Yao: Annealing effect on the shape memory properties of amorphous NiTi thin films. J. Manuf. Sci. Eng. 132, 051004 (2010).

Y-H. Li, G-B. Rao, L-J. Rong, and Y-Y. Li: The influence of porosity on corrosion characteristics of porous NiTi alloy in simulated body fluid. Mater. Lett. 57, 448 (2002).

G.A. Shaw, D.S. Stone, A.D. Johnson, A.B. Ellis, and W.C. Crone: Shape memory effect in nanoindentation of nickel–titanium thin films. Appl. Phys. Lett. 83, 257 (2003).

W. Ni, Y.T. Cheng, and D.S. Grummon: Microscopic shape memory and superelastic effects under complex loading conditions. Surf. Coat. Technol. 177-178, 512 (2004).

X-G. Ma and K. Komvopoulos: Pseudoelasticity of shape-memory titanium–nickel films subjected to dynamic nanoindentation. Appl. Phys. Lett. 84, 4274 (2004).

W.M. Huang, J.F. Su, M.H. Hong, and B. Yang: Pile-up and sink-in in micro-indentation of a NiTi shape-memory alloy. Scr. Mater. 53, 1055 (2005).

A. Amini, W. Yan, and Q. Sun: Depth dependency of indentation hardness during solid-state phase transition of shape memory alloys. Appl. Phys. Lett. 99, 021901 (2011).

A. Amini, Y. He, and Q. Sun: Loading rate dependency of maximum nanoindentation depth in nano-grained NiTi shape memory alloy. Mater. Lett. 65, 464 (2011).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

W. Yan, Q. Sun, and H-Y. Liu: Effect of transformation volume strain on the spherical indentation of shape memory alloys. Int. J. Mod. Phys. B 22, 5957 (2008).

G. Kang and W. Yan: Effects of phase transition on the hardness of shape memory alloys. Appl. Phys. Lett. 94, 261906 (2009).

G. Kang and W. Yan: Scaling relationships in sharp conical indentation of shape memory alloys. Philos. Mag. 90, 599 (2010).

W. Yan, Q. Sun, and H.-Y. Liu: Spherical indentation hardness of shape memory alloys. Mater. Sci. Eng., A 425, 278 (2006).

K.L. Johnson: Contact Mechanics (Cambridge University Press, Cambridge, England, 1985), p. 100.

L. Qian, X. Xiao, Q. Sun, and T. Yu: Anomalous relationship between hardness and wear properties of a superelastic nickel-titanium alloy. Appl. Phys. Lett. 84, 1076 (2004).

Acknowledgments

This study has been partially supported by the Hong Kong Research Grants Council under CERG Grant No. 620109. The computational simulations were carried out at the NCI National Facility in Canberra, Australia, which is supported by the Australian Commonwealth Government.

Author information

Authors and Affiliations

Corresponding author

Appendix: Numerical Method to Estimate the Interfacial Area and the Transformation Zone Volume

Appendix: Numerical Method to Estimate the Interfacial Area and the Transformation Zone Volume

The method to estimate the interfacial area and the transformation zone volume from the FE simulations is detailed in this appendix. Applying the FE model presented in the paper, the spherical indentation test of SMAs can be simulated. Figure A1 shows a typical distribution of the phase transformation strain under indentation, which is used to define the phase transformation zone. The phase transformation zone boundary has the equivalent phase transformation strain value of 0.2%, which is the same as the plastic strain value used to define proof stress in classical elasto-plastic problems.

To estimate the interfacial area and the phase transformation zone volume, the irregular phase transition zone from the FE simulations is approximated by a cylinder with the radius of atr and the depth of btr. Both the parameters are defined in Fig. A1. The interfacial area Ai can be estimated as

The volume Vm of the phase transformation zone can be estimated as

It is worth commenting that the presented method to estimate the interfacial area and the transformation zone volume serves the purpose to qualitatively analyze the indentation problem to get a simple scaling of the problem. It is not an accurate study.

Rights and permissions

About this article

Cite this article

Yan, W., Amini, A. & Sun, Q. On anomalous depth-dependency of the hardness of NiTi shape memory alloys in spherical nanoindentation. Journal of Materials Research 28, 2031–2039 (2013). https://doi.org/10.1557/jmr.2013.184

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2013.184