Abstract

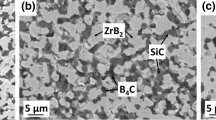

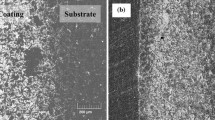

Theoretically dense ZrB2-SiC two-phase microstructures were isothermally oxidized for ~90 min in flowing air in the range 1500-1900 °C. Specimens with 30 mol% SiC formed distinctive reaction product layers that were highly protective; 28 mol% SiC-6 mol% TaB2 performed similarly. At and above 1700 °C, the composition with only 15 mol% SiC oxidized extensively because of deficient silicate liquid formation. Specimens with 60 mol% SiC were resistant to oxidation up to 1800 °C; at 1900 °C, this composition displayed periodic ruptures of the passivating layer by emerging gas bubbles. Oxide coating thicknesses calculated from weight loss data were consistent with those measured from scanning electron microscopy micrographs. A layer of ZrB2 devoid of SiC was argued to be from preferential removal of SiC by reaction of a silica oxidation product with adjacent unreacted SiC to form escaping gases.

Similar content being viewed by others

References

F. Peng, Y. Berta, and R.F. Speyer: Effect of SiC, TaB2 and TaSi2 additives on the isothermal oxidation resistance of fully dense zirconium diboride. J. Mater. Res. 24(5), 1855 (2009).

R.F. Speyer: Effect of SiC, TaB2 and TaSi2 additives on the isothermal oxidation resistance of fully dense zirconium diboride, presented at the Workshop on Aerospace Materials for Extreme Environments (AFORS, Clayton MO, Aug. 5, 2009).

S.N. Karlsdottir, J.W. Halloran, and A.N. Grundy: Zirconia transport by liquid convection during oxidation of zirconium diboride-silicon carbide. J. Am. Ceram. Soc. 91(1), 272 (2008).

E.J. Opila and M.C. Halbig: Oxidation of ZrB2-SiC. Elec. Chem. Soc. Proc. 12, 221 (2002).

A. Rezaie, W.G. Fahrenholtz, and G.E. Hilmas: Evolution of structure during the oxidation of zirconium diboride-silicon carbide in air up to 1500 °C. J. Europ. Ceram. Soc. 27, 2495 (2007).

W.G. Fahrenholtz: Thermodynamic analysis of ZrB2-SiC oxidation: Formation of a SiC-depleted region. J. Am. Ceram. Soc. 90(1), 143 (2007).

M. Opeka, I. Talmy, and J. Zaykoski: Oxidation-based materials selection for 2000 °C + hypersonic aerosurfaces: Theoretical considerations and historical experience. J. Mater. Sci. 39, 5887 (2004).

A.R. Rezaie, W.G. Fahrenholtz, and G.E. Hilmas: Oxidation of zirconium diboride-silicon carbide at 1500 °C in a low partial pressure of oxygen. J. Am. Ceram. Soc. 89(10), 3240 (2006).

J. Han, P. Hu, X. Zhang, and S. Meng: Oxidation behavior of zirconium diboride-silicon carbide at 1800 °C. Scripta Mater. 57, 825 (2007).

W. Han, P. Hu, X. Zhang, J. Han, and S. Meng: High-temperature oxidation at 1900 °C of ZrB2-xSiC ultrahigh-temperature ceramic composites. J. Am. Ceram. Soc. 91(10), 3328 (2008).

S.N. Karlsdottir and J.W. Halloran: Rapid oxidation characterization of ultra-high temperature ceramics. J. Am. Ceram. Soc. 90(10), 3233 (2007).

P. Hu, X. Zhang, J. Han, X. Luo, and S. Du: Effect of various additives on the oxidation behavior of ZrB2-based ultra-high-temperature ceramics at 1800 °C. J. Am. Ceram. Soc. 93(2), 345–349 (2010).

X. Zhang, P. Hu, J. Han, and S. Meng: Ablation behavior of ZrB2-SiC ultra high temperature ceramics under simulated atmosphere reentry conditions. Comp. Sci. Technol. 68, 1718 (2008).

F. Monteverde, R. Savino, M.D.S. Fumo, and A.D. Maso: Plasma wind tunnel testing of ultra-high temperature ZrB2-SiC composites under hypersonic re-entry conditions. J. Euro. Ceram. Soc. 30, 2313 (2010).

F. Monteverde and R. Savino: Stability of ultra-high temperature ZrB2-SiC ceramics under simulated atmospheric re-entry conditions. J. Euro. Ceram. Soc. 27, 4797 (2007).

J. Han, P. Hu, X. Zhang, S. Meng, and W. Han: Oxidation-resistant ZrB2-SiC composites at 2200 °C. Comp. Sci. Technol 68, 799 (2008).

R.F. Speyer: Thermal Analysis of Materials (Marcel Dekker, New York, 1994).

M.W. Clase, Jr: NIST-JANAF thermochemical tables, in J. Phys. Chem. Ref. Data, Monograph 9, 4th Ed. (American Institute of Physics, Woodbury, NY, 1998).

Acknowledgments

This project was funded by the Air Force Office of Scientific Research, Contract FA9550-04-1-0140. The authors would like to express their appreciation for the helpful suggestions and support of their contract monitor, Dr. Joan Fuller. The authors are grateful to Professor Jeffrey Furgus of Auburn University for the use of his zirconia heating element furnace.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

For the reactions

and

it is assumed that boron oxide forms as an escaping gas and silica forms as a liquid/glass. These reaction stoichiometries dictate that the number of moles of ZrO2 formed are equal to the number of moles of ZrB2 consumed, \({n_{{\text{Zr}}{{\text{O}}_{\text{2}}} = }}{n_{{\text{Zr}}{{\text{B}}_{\text{2}}}}}\), and similarly \(n{\text{Si}}{{\text{O}}_2} = n{\text{SiC}}\). Note that the latter equality holds even if the reaction produced CO as opposed to CO2.

Let ΔM be the measured mass change after 100 min exposure to a given oxidation temperature. Then:

where \({M_{{\text{Zr}}{{\text{B}}_2}}}\) and MSiC are the masses of zirconium diboride and silicon carbide converted, respectively, and \({M_{{\text{Zr}}{{\text{O}}_2}}}\) and \({M_{{\text{Si}}{{\text{O}}_2}}}\) are the masses of zirconia and silica produced, respectively. Letting W be the molar mass:

We define XSiC as the mole fraction of SiC in the original ZrB2–SiC composition, thus:

Let ρ be the density and V′ be the volume of oxide formed:

Given a disk geometry for the partially oxidized specimen of diameter d and height h, with a uniform oxide coating thickness of T:

The diameter d and height h of the disk vary during oxidation because the densities of the consumed phases and the corresponding formed oxide phases are not the same. Let ΔV be the volume of products formed minus the volume of reactants consumed; that is, the change in volume of the disk. Recognizing the equivalence of moles of ZrB2/ZrO2 and SiC/SiO2:

If the dimensions of the disk before oxidation are d0 and h0, then after partial oxidation, the change in volume is

Assuming that the thickness of oxide scale forming on all surfaces is the same, the change in linear dimensions from oxidation in the axial and radial directions would then be the same: d − d0 = h − h0, thus:

Equation (A2) (inserting into Eq. (A1) and the definition of mole fraction) may be used to determine the volume of oxide formed. Inserting this into Eq.(A3), along with calculated values of d and h from Eqs. (A4) and (A5) will yield T through numerical solution.

Rights and permissions

About this article

Cite this article

Peng, F., Van Laningham, G. & Speyer, R.F. Thermogravimetric analysis of the oxidation resistance of ZrB2-SiC and ZrB2-Sic-TaB2-based compositions in the 1500-1900 °C range. Journal of Materials Research 26, 96–107 (2011). https://doi.org/10.1557/jmr.2010.38

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2010.38