Abstract

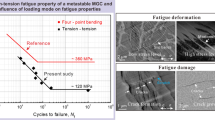

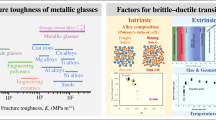

A major drawback in using bulk metallic glasses (BMGs) as structural materials is their extremely poor fatigue performance. One way to alleviate this problem is through the composite route, in which second phases are introduced into the glass to arrest crack growth. In this paper, the fatigue crack growth behavior of in situ reinforced BMGs with crystalline dendrites, which are tailored to impart significant ductility and toughness to the BMG, was investigated. Three composites, all with equal volume fraction of dendrite phases, were examined to assess the influence of chemical composition on the near-threshold fatigue crack growth characteristics. While the ductility is enhanced at the cost of yield strength vis-à-vis that of the fully amorphous BMG, the threshold stress intensity factor range for fatigue crack initiation in composites was found to be enhanced by more than 100%. Crack blunting and trapping by the dendritic phases and constraining of the shear bands within the interdendritic regions are the micromechanisms responsible for this enhanced fatigue crack growth resistance.

Similar content being viewed by others

References

C.A. Schuh, T.C. Hufnagel, and U. Ramamurty: Mechanical behavior of amorphous alloys. Acta Mater. 55, 4067 (2007).

C.J. Gilbert, V. Schroeder, and R.O. Ritchie: Mechanisms for fracture and fatigue-crack propagation in a bulk metallic glass. Metall. Mater. Trans. A 30, 1739 (1999).

R. Raghavan, R. Ayer, H.W. Jin, C.N. Marzinsky, and U. Ramamurty: Effect of shot peening on the fatigue life of a Zr-based bulk metallic glass. Scr. Mater. 59, 167 (2008).

R. Bhowmick, R. Raghavan, K. Chattopadhyay, and U. Ramamurty: Plastic flow softening in a bulk metallic glass. Acta Mater. 54, 4221 (2006).

B.G. Yoo, K.W. Park, J.C. Lee, U. Ramamurty, and J. Jang: Role of free volume in strain softening of as-cast and annealed bulk metallic glass. J. Mater. Res. 24, 1405 (2009).

N. Nagendra, U. Ramamurty, T.T. Goh, and Y. Li: Effect of crystallinity on the impact toughness of a La-based bulk metallic glass. Acta Mater. 48, 2603 (2000).

J. Basu, N. Nagendra, Y. Li, and U. Ramamurty: Microstructure and mechanical properties of partially-crystallized La-based bulk metallic glass. Philos. Mag. 83, 1747 (2003).

R. Raghavan, P. Murali, and U. Ramamurty: On the factors influencing the ductile to brittle transition in a bulk metallic glass. Acta Mater. 57, 3332 (2009).

R. Raghavan, V.V. Shastry, A. Kumar, T. Jayakumar, and U. Ramamurty: Toughness of as cast and partially recrystallized Zr-based bulk metallic glass. Intermetallics 17, 835 (2009).

T. Liu, P. Shen, F. Qiu, Z. Yin, Q. Lin, Q. Jiang, and T. Zhang: Synthesis and mechanical properties of TiC-reinforced Cu-based bulk metallic glass composites. Scr. Mater. 60, 84 (2009).

C.C. Hays, C.P. Kim, and W.L. Johnson: Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 84, 2901 (2000).

F. Szuecs, C.P. Kim, and W.L. Johnson: Mechanical properties of Zr56.2Ti13.8Nb5.0Cu6.9Ni5.6Be12.5 ductile phase reinforced bulk metallic glass composite. Acta Mater. 49, 1507 (2001).

Z. Bian, H. Kato, C. Qin, W. Zhang, and A. Inoue: Cu–Hf–Ti–Ag–Ta bulk metallic glass composites and their properties. Acta Mater. 53, 2037 (2005).

C.L. Qin, W. Zhang, K. Asami, H. Kimura, X.M. Wang, and A. Inoue: A novel Cu-based BMG composite with high corrosion resistance and excellent mechanical properties. Acta Mater. 54, 3713 (2006).

D.C. Hofmann, J.Y. Suh, A. Wiest, G. Duan, M.L. Lind, M.D. Demetriou, and W.L. Johnson: Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 451, 1086 (2008).

M.E. Launey, D.C. Hofmann, J.Y. Suh, H. Kozachkov, W.L. Johnson, and R.O. Ritchie: Fracture toughness and crack-resistance curve behavior in metallic glass-matrix composites. Appl. Phys. Lett. 94, 241910 (2009).

S. Suresh: Fatigue of Materials, 2nd ed. (Cambridge University Press, Cambridge, 1998).

M. Flores, W.L. Johnson, and R.H. Dauskardt: Fracture and fatigue behavior of a Zr–Ti–Nb ductile phase reinforced bulk metallic glass matrix composite. Scr. Mater. 49, 1181 (2003).

G.Y. Wang, P.K. Liaw, A. Peker, M. Freels, W.H. Peter, R.A. Buchanan, and C.R. Brooks: Comparison of fatigue behavior of a bulk metallic glass and its composite. Intermetallics 14, 1091 (2006).

M.E. Launey, D.C. Hofmann, W.L. Johnson, and R.O. Ritchie: Solution to the problem of the poor cyclic fatigue resistance of bulk metallic glasses. Proc. Nat. Acad. Sci. U.S.A. 106, 4986 (2009).

G. Subhash, R.J. Dowding, and L.J. Kecskes: Characterization of uniaxial compressive response of a bulk amorphous Zr–Ti–Cu–Ni–Be alloy. Mater. Sci. Eng.A, 234, 33 (2002).

D.C. Hofmann, J.Y. Suh, A. Wiest, M.L. Lind, M.D. Demetriou, and W.L. Johnson: Development of tough, low-density titanium-based bulk metallic glass matrix composites with tensile ductility. Proc. Nat. Acad. Sci. U.S.A. 105, 20136 (2008).

Standard test method for measurement of fatigue crack-growth rates. E 647–05. (ASTM International, W. Conshohocken, PA, 2005), p. 1-45.

A. Leonhard, L.Q. Xing, M. Heilmaier, A. Gebert, J. Eckert, and L. Schultz: Effect of crystalline precipitations on the mechanical behavior of bulk glass forming Zr-based alloys. Nanostruct. Mater. 10, 805 (1998).

H. Zhang, Z.G. Wang, K.Q. Qiu, Q.S. Zang, and H.F. Zhang: Cyclic deformation and fatigue crack propagation of a Zr-based bulk amorphous metal. Mater. Sci. Ew.A, 356, 173 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boopathy, K., Hofmann, D.C., Johnson, W.L. et al. Near-threshold fatigue crack growth in bulk metallic glass composites. Journal of Materials Research 24, 3611–3619 (2009). https://doi.org/10.1557/jmr.2009.0439

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0439