Abstract

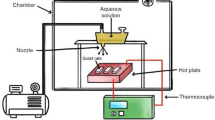

To investigate the microwave (MW) processing of Fe3O4, for which occurrence of decrystallization has been reported, the micro/nanostructures of MW-heated Fe3O4 powder were observed in this study. The specimens were irradiated by 2.45 GHz MW at the position of magnetic (H)-field maximum in a TE10 single mode applicator. The specimen was heated well above the Curie temperature in H-field. The heated specimen above 1000 °C revealed the glass-like surface with the diminished x-ray diffraction (XRD) peak intensities. They resemble the reported features of decrystallization in an earlier work performed at Penn State University. According to the XRD profiles of the MW-heated specimens, formation of FeO and shift of Fe3O4 peaks to the lower angle with the broadened width were observed. To account for the findings, a model is presented that phase separation occurred into FeO and Fe3O4 resulting in an increased lattice parameter due to the increased oxygen content. This activity is caused by local transport of oxygen in nanoscale. Considering the shape of the main XRD Fe3O4 peak with a shoulder and the existence of halo in nanobeam diffraction (NBD), amorphous phase areas exist. As a result of transmission electron microscopy observation, it was shown that they were in nanoscaled localized regions, and it was not confirmed that the glass-like morphologies (or decrystallized morphologies) are totally amorphous. The observed micro/nanostructures and mechanism of the amorphous phase formation were discussed considering the Fe-O phase diagram.

Similar content being viewed by others

References

J.D. Katz: Microwave sintering of ceramics. Annu. Rev. Mater. Sci. 22, 153 (1992).

D.E. Clark and W.H. Sutton: Microwave processing of materials. Annu. Rev. Mater. Sci. 26, 299 (1996).

R. Wroe and A.T. Rowley: Evidence for a non-thermal microwave effect in the sintering of partially stabilized zirconia. J. Mater. Sci. 31, 2019 (1996).

Y.V. Bykov, K.I. Rybakov, and V.E. Semenov: High-temperature microwave processing of materials. J. Phys. D: Appl. Phys. 34, R55 (2001).

Microwave processing of materials. Committee on Microwave Proc. of Mater.: An Emerging Industrial Technology, editor (National Academy Press, Washington, DC, 1994), p. 2.

M. Sato, R. Roy, P. Ramesh, and D. Agrawal: Microscopic non-equilibrium heating a possible mechanism of microwave effects, in Proc. Int. Symp. on Microwave Science and its Application to Related Fields (Takamatsu, Japan, 2004), pp. 339–340.

R. Roy, R. Peelamedu, L. Hurtt, J. Cheng, and D. Agrawal: Definitive experimental evidence for microwave effects: Radically new effects of separated E and H fields, such as decrystallization of oxides in seconds. Mater. Res. Innovations 6, 128 (2002).

J. Cheng, R. Roy, and D. Agrawal: Experimental proof of major role of magnetic field losses in microwave heating of metallic composites. J. Mater. Sci. Lett. 20, 1561 (2001).

T. Kimura, H. Takizawa, K. Ueda, and T. Endo: Microwave synthesis of x-ray amorphous ferrites and the magnetic properties, in Proc. Inf. Conf. Microwave Chemistry (2000), p. 335.

R. Roy, R. Peelamedu, C. Grimes, J. Cheng, and D. Agrawal: Major phase transformation and magnetic property changes caused by electromagnetic fields at microwave frequency. J. Mater. Res. 17 (12), 3008 (2002).

R. Peelamedu, R. Roy, L. Hurtt, D. Agrawal, A.W. Fliflet, D. Lewis III, and R. Bruce: Phase formation and decrystallization effects on BaCO3 + 4Fe3O4 mixtures; A comparison of 83 GHz, multimode millimeter-wave and 2.45 GHz single mode microwave H-field processing. Mater. Chem. Phys. 88, 119 (2004).

R. Roy, Y. Fang, J. Cheng, and D.A. Grawal: Decrystallizing solid crystalline titania, without melting using microwave magnetic field. J. Am. Ceram. Soc. 88 (6), 1640 (2005).

R. Peelamedu, R. Roy, D. Agrawal, and W. Drawl: Field decrystallization and structural modification of highly doped silicon in a 2.45 GHz microwave single-mode cavity. J. Mater. Res. 19 (6), 1599 (2004).

N. Yoshikawa, E. Ishizuka, and S. Taniguchi: Heating of metal particles in a single-mode microwave applicator. Mater. Trans. 47 (3), 898 (2006).

O. Kubaschewski: Iron-Binary Phase Diagrams (Springer-Verlag, Berlin, Germany, 1982), p. 80.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoshikawa, N., Cao, Z., Louzguin, D. et al. Micro/nanostructure observation of microwave-heated Fe3O4. Journal of Materials Research 24, 1741–1747 (2009). https://doi.org/10.1557/jmr.2009.0192

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2009.0192