Abstract

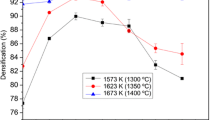

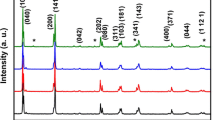

Dense β-Si4Al2O2N6 and β-Si4Al2O2N6-0.5SiO2 ceramics were obtained from α-Si3N4, α-Al2O3, AlN, and Y2O3 upon sintering green bodies consolidated by aqueous gel casting. For comparison purposes, a β-Si4Al2O2N6 was also prepared by the conventional dry-powder processing route. In the case of gel-cast β-Si4Al2O2N6, the as-purchased AlN powder was treated with H3PO4 and Al(H2PO4)3 prior to use along with α-Si3N4, α-Al2O3, and Y2O3. The gel-cast β-Si4Al2O2N6 exhibited superior hardness (1423 ± 6 Hv), fracture toughness (3.95 ± 0.3 MPa⋅m1/2), and coefficient of thermal expansion (CTE) (3.798 × 10−6/°C between 30 and 1000 °C) in comparison to the ceramic consolidated by conventional dry pressing, which exhibited only 1317 ± 5 Hv, 3.30 ± 0.2 MPa⋅m1/2, and 3.532 × 10−6/°C between 30 and 700 °C. The in situ-generated ∼9 wt% SiO2 has considerably reduced the dielectric constant and CTE of β-Si4Al2O2N6 from 7.30 to 6.32 and from 3.798 × 10−6/°C to 3.519 × 10−6/°C, respectively. The loss tangent property of the investigated materials was little influenced by the variation of chemical composition and processing route.

Similar content being viewed by others

References

Y. Oyama O. Kamagaito: Solid solubility of some oxides in Si3N4. Jpn. J. Appl. Phys. 10, 1637 1971

K.H. Jack W.I. Wilson: Ceramics based on the Si–Al–O–N and related systems. Nature (London) 238, 28 1977

K.H. Jack: Review: SiAlONs and related nitrogen ceramics. J. Mater. Sci. 11, 1135 1976

K.H. Jack: SiAlONs: A Study in Materials Development, Non-Oxide Technical and Engineering Ceramics edited by S. Hampshire Elsevier Applied Science Publishers Ltd. Barking, Essex, England 1986 1–30

I.W.M. Brown, G.C. Barris, M.E. Bowden, K.J.D. Mackenzie, C.M. Sheppard G.V. White: Synthesis, densification, and properties of SiAlON bodies and composites in SiAlONs edited by K. Komeya, M. Mitomo, and Y.B. Cheng Key Engineering Materials, Trans Tech Publications Ltd. Enfield, NH 2001

M.A. Janney, C.A. Walls, D.M. Kupp K.W. Kirby: Gelcasting SiAlON radomes. Am. Ceram. Soc. Bull. 83, 9201 2004

K.W. Kirby, A.T. Jankiewicz, M.A. Janney, C. Walls D. Kupp: Gelcasting of GD-1 ceramic radomes in Proceedings of the 8th DoD Electromagnetic Windows Symposium, U.S. Air Force Academy Colorado Springs, CO, April 24–27, 2000, pp. 287–295 (2000)

K.W. Kirby, A.T. Jankiewicz, R.F. Lowell R.L. Hallse: Near net shape fabrication of ceramic radomes. U.S. Patent No. 6,083,452, July 4, 2000

K.W. Kirby, A. Jankiewcz, D. Kupp, C. Walls M. Janney: Gelcasting of ceramic radomes in the Si3N4–Al2O3–AlN–SiO2 system. Mater. Technol. Adv. Perf. Mater. 16(3), 187 2001

V.A. Izhevskiy, L.A. Genova, J.C. Bressiani F. Aldinger: Progress in SiAlON ceramics. J. Eur. Ceram. Soc. 20, 2275 2000 and references therein

J.F. Yang, G.J. Zhang, J.H. She, T. Ohji S. Kanzaki: Improvement of mechanical properties and corrosion resistance of porous β-SiAlON ceramics by low Y2O3 additions. J. Am. Ceram. Soc. 87(9), 1714 2004

X. Xu J.M.F. Ferreira: Temperature-induced gelation of concentrated SiAlON suspensions. J. Am. Ceram. Soc. 88(3), 593 2005

X. Xu, M.I.L.L. Oliveira, F. Renli J.M.F. Ferreira: Effect of dispersant on the rheological properties and slip casting of concentrated SiAlON precursor suspensions. J. Eur. Ceram. Soc. 23(9), 1525 2003

S.J. Stedman, J.R.G. Evans, R.J. Brook M.J. Hoffmann: Anisotropic sintering shrinkage in injection moulding composite ceramics. J. Eur. Ceram. Soc. 11(6), 523 1993

I. Ganesh, N. Thiyagarajan, D.C. Jana, P. Barick, G. Sundararajan J.M.F. Ferreira: Dense β-SiAlONs consolidated by a modified hydrolysis assisted solidification route. J. Eur. Ceram. Soc. 28(4), 879 2008

T. Kosmac, S. Novak M. Sajko: Hydrolysis-assisted solidification (HAS): A new setting concept for ceramic net-shaping. J. Eur. Ceram. Soc. 17, 427 1997

S. Novak, T. Kosmac, K. Krnel G. Draz: Principles of the hydrolysis assisted solidification (HAS) process for forming ceramic bodies from aqueous suspension. J. Eur. Ceram. Soc. 22, 289 2002

M.A. Janney, S.D. Nunn, C.A. Walls, O.O. Omatete, R.B. Ogle, G.H. Kirby A.D. McMillan: Gelcasting in The Handbook of Ceramic Engineering edited by M.N. Rahman Marcel Dekker New York 1998 1–15

I. Ganesh, N. Thiyagarajan, D.C. Jana, Y.R. Mahajan G. Sundararajan: Influence of chemical composition and Y2O3 on sinterability, dielectric constant and CTE of β-SiAlON. J. Am. Ceram. Soc. 91(1), 115 2008

G. Gilde, P. Patel, C. Hubbard, B. Pothier, T. Hynes, W. Croft J. Wells: SiON low dielectric constant ceramic nanocomposite. U.S. Patent No. 5,677,252, Oct. 14, 1997

F.M. Uenishi, K.N.Y. Hashizume T. Yokote: Aluminum nitride powder having improved water resistance. U.S. Patent No. 4,923,689, May 8, 1990

K. Krnel T. Kosmac: Protection of AlN powder against hydrolysis using aluminum di-hydrogen phosphate. J. Eur. Ceram. Soc. 21, 2075 2001

S.M. Olhero, S. Novak, M. Oliveira, K. Krnel, T. Kosmac J.M.F. Ferreira: A thermochemical surface treatment of AlN powder for the aqueous processing of AlN ceramics. J. Mater. Res. 19, 746 2004

I. Ganesh, D.C. Jana, S. Shaik N. Thiyagarajan: An aqueous gelcasting process for sintered silicon carbide ceramics. J. Am. Ceram. Soc 89, 3056 2006

H.P. Klug L.E. Alexander: X-ray diffraction procedure for polycrystalline and amorphous materials. J. Appl. Crystallogr., 8, 573 1975

I. Ganesh, K.A. Teja, N. Thiyagarajan, R. Johnson B.M. Reddy: Formation and densification behavior of magnesium aluminate spinel: The influence of CaO and moisture in the precursors. J. Am. Ceram. Soc. 88(10), 2752 2005

I-L. Ekberg, R. Lundberg, R. Warren R. Carlson: Brittle Matrix Composites 2 edited by A.M. Brandt and I.H. Marshall Elsevier Applied Science New York 1998

A.M. Nicolson G.F. Ross: Measurement of the intrinsic properties of materials by time domain techniques. IEEE Trans. Instrum. Meas. IM-19, 377 1970

S. Hampshire, H.K. Park, D.P. Thompson H.K. Jack: α′-SiAlON. Nature 274, 880 1978

P. Pettersson, Z. Shen, M. Johnsson M. Nygren: Thermal shock properties of β-SiAlON ceramics. J. Eur. Ceram. Soc 22, 1357 2002

R.C. Buchanan: Properties of ceramic insulators in Ceramic Materials for Electronics: Processing, Properties and Applications 2nd ed. revised and expanded, edited by R.C. Buchanan Marcel Dekker Inc. New York 1991 Chap. 1

V. Raghavan: Dielectric materials in Materials Science and Engineering—A First Course 4th ed. Prentice-Hall of India (P) Ltd. New Delhi 1998 Chap. 17

J.A. Dean: (ed.) Lange’s Handbook of Chemistry 12th ed. McGraw-Hill New York 1979

D.R. Lide: (ed.) CRC Handbook of Chemistry and Physics 73rd ed. CRC Press London 1993

Acknowledgments

I.G. thanks SERC-DST (Government of India) for the awarded BOYSCAST fellowship (SR/BY/E-04/06). S.M.O. thanks the Foundation for Science and Technology of Portugal for financial support under grant SFRH/BPD/27013/2006. Financial support of CICECO is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ganesh, I., Thiyagarajan, N., Jana, D. et al. Influence of processing route and SiO2 on sintering ability, CTE, and dielectric constant of β-Si4Al2O2N6. Journal of Materials Research 23, 2305–2311 (2008). https://doi.org/10.1557/jmr.2008.0302

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2008.0302