Abstract

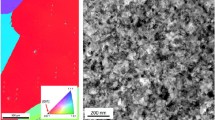

A bulk nanocrystalline (nc) Ni–Fe alloy was subjected to tensile deformation, which leads to grain growth. The nanoindentation study indicates that the hardness, H, and Young’s modulus, E, of the nc alloy before and after tensile deformation did not show a clear indentation-rate effect. However, the tensile deformation results in a decrease in the E values of about 15%, which might be attributed to the grain rotation, leading to texture development during the stress-induced grain growth.

Similar content being viewed by others

References

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

K.S. Kumar, H. Van Swygenhoven, and S. Suresh: Mechanical behavior of nanocrystalline metals and alloys. Acta Mater. 51, 5743 (2003).

T.G. Nieh and J. Wadsworth: Hall-Petch relation in nanocrystalline solids. Scripta Metall. Mater. 25, 955 (1991).

J. Schiotz, F.D. Di Tolla, and K.W. Jacobsen: Softening of nanocrystalline metals at very small grain sizes. Nature 391, 561 (1998).

H. Van Swygenhoven and P.M. Derlet: Grain-boundary sliding in nanocrystalline fcc metals. Phys. Rev. B: Condens. Matter 64, 224105 (2001).

D. Wolf, V. Yamakov, S.R. Phillpot, A. Mukherjee, and H. Gleiter: Deformation of nanocrystalline materials by molecular-dynamics simulation: relationship to experiments? Acta Mater. 53, 1 (2005).

G.J. Fan, H. Choo, P.K. Liaw, and E.J. Lavernia: Strength softening and stress relaxation of nanostructured materials. Metall. Trans. A 36, 2641 (2005).

C.A. Schuh, T.G. Nieh, and H. Iwasaki: The effect of solid solution W additions on the mechanical properties of nanocrystalline Ni. Acta Mater. 51, 431 (2003).

R. Schwaiger, B. Moser, M. Dao, N. Chollacoop, and S. Suresh: Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 51, 5159 (2003).

F.Q. Yang, W.W. Du, and K. Okazaki: Effect of cold rolling on the indentation deformation of AA6061 aluminum alloy. J. Mater. Res. 20, 1172 (2005).

K.J. Van Vliet, S. Tsikata, and S. Suresh: Model experiments for direct visualization of grain boundary deformation in nanocrystalline metals. Appl. Phys. Lett. 83, 1441 (2003).

Y.M. Wang, A.M. Hodge, J. Biener, A.V. Hamza, D.E. Barnes, K. Liu, and T.G. Nieh: Deformation twinning during nanoindentation of nanocrystalline Ta. Appl. Phys. Lett. 86, 101915 (2005).

M. Zhang, B. Yang, J. Chu, and T.G. Nieh: Hardness enhancement in nanocrystalline tantalum thin films. Scripta Mater. 54, 1227 (2006).

W.H. Jiang and M. Atzmon: Rate dependence of serrated flow in a metallic glass. J. Mater. Res. 18, 755 (2003).

K. Zhang, J.R. Weertman, and J.A. Eastman: The influence of time, temperature, and grain size on indentation creep in high-purity nanocrystalline and ultrafine grain copper. Appl. Phys. Lett. 85, 5197 (2004).

M. Jin, A.M. Minor, E.A. Stach, and J.W. Morris: Direct observation of deformation-induced grain growth during the nanoindentation of ultrafine-grained Al at room temperature. Acta Mater. 52, 5381 (2004).

G.J. Fan, Y.D. Wang, L.F. Fu, H. Choo, P.K. Liaw, Y. Ren, and N.D. Browning: Orientation-dependent grain growth in a bulk nanocrystalline alloy during the uniaxial compressive deformation. Appl. Phys. Lett. 88, 171914 (2006).

X.Z. Liao, A.R. Kilmametov, R.Z. Valiev, H.S. Gao, X.D. Li, A.K. Mukherjee, J.F. Bingert, and Y.T. Zhu: High-pressure torsion-induced grain growth in electrodeposited nanocrystalline Ni. Appl. Phys. Lett. 88, 021909 (2006).

D.S. Gianola, S.V. Petegem, M. Legros, S. Brandstetter, H. Van Swygenhoven, and K.J. Hemker: Stress-assisted discontinuous grain growth and its effect on the deformation behavior of nanocrystalline aluminum thin films. Acta Mater. 54, 2253 (2006).

G.J. Fan, L.F. Fu, D.C. Qiao, H. Choo, P.K. Liaw, and N.D. Browning: Grain growth in a bulk nanocrystalline Co alloy during tensile plastic deformation. Scripta Mater. 54, 2137 (2006).

G.J. Fan, L.F. Fu, H. Choo, P.K. Liaw, and N.D. Browning: Uniaxial tensile plastic deformation and grain growth of bulk nanocrystalline alloys. Acta Mater. 54, 4781 (2006).

G.J. Fan, L.F. Fu, Y.D. Wang, Y. Ren, H. Choo, P.K. Liaw, G.Y. Wang, and N.D. Browning: Uniaxial tensile plastic deformation of a bulk nanocrystalline alloy studied by a high-energy x-ray diffraction technique. Appl. Phys. Lett. 89, 101918 (2006).

J. Chen, Y.N. Shi, and K. Lu: Strain rate sensitivity of a nanocrystalline Cu-Ni-P alloy. J. Mater. Res. 20, 2955 (2005).

D. Pan, T.G. Nieh, and M.W. Chen: Strengthening and softening of nanocrystalline nickel during multistep nanoindentation. Appl. Phys. Lett. 88, 161922 (2006).

R. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials4th ed. (Wiley, New York, NY, 1996) p. 6.

M. Legros, B.R. Elliott, M.N. Rittner, J.R. Weertman, and K.J. Hemker: Microsample tensile testing of nanocrystalline metals. Philos. Mag. A 80, 1017 (2000).

P. Sanders, C.P. Youngdahl, and J.R. Weertman: The strength of nanocrystalline metals with and without flaws. Mater. Sci. Eng., A 234–236, 77 (1997).

H. Huang and F. Spaepen: Tensile testing of free-standing Cu, Ag and Al thin films and Ag/Cu multilayers. Acta Mater. 48, 3261 (2000).

Y. Zhou, U. Erb, K.T. Aust, and G. Palumbo: Young’s modulus in nanostructured metals. Z. Metallkd. 94, 1157 (2003).

X.H. Zeng and T. Ericsson: Anisotropy of elastic properties in various aluminium-lithium sheet alloys. Acta Mater. 44, 1801 (1996).

Y.B. Park, D.N. Lee, and G. Gottstein: The evolution of recrystallization textures in body centred cubic metals. Acta Mater. 10, 3371 (1998).

D.C. Hurley, R.H. Geiss, M. Kopycinska-Muller, J. Muller, D.T. Read, J.E. Wright, N.M. Jennett, and A.S. Maxwell: Anisotropic elastic properties of nanocrystalline nickel thin films. J. Mater. Res. 20, 1186 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, G.J., Jiang, W.H., Liu, F.X. et al. The effects of tensile plastic deformation on the hardness and Young’s modulus of a bulk nanocrystalline alloy studied by nanoindentation. Journal of Materials Research 22, 1235–1239 (2007). https://doi.org/10.1557/jmr.2007.0147

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2007.0147