Abstract

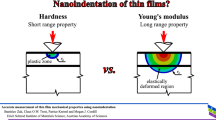

Poly(methyl methacrylate) was contacted by a Berkovich indenter at a range of constant loading strain rates. This particular loading scheme was used to maintain the strain-rate-dependent elastic modulus and indentation hardness of the creeping solid constant throughout loading. A loading curve analysis method identical to that of Malzbender and de With but based on the elastic-perfectly plastic contact model of Hochstetter et al. [Tribol. Int. 36, 973–985, 2003] was used to process the load-displacement curves. Using the analysis method together with the strain-rate-dependent elastic modulus of the creeping solid known a priori, the strain-rate-dependent hardness could then be predicted. The predicted hardness versus strain-rate relationship was compared with that evaluated from the observed topographic images of the residual impressions due to heavier indentations at three constant loading strain rates. Based on this comparison, the elastic-perfectly plastic contact model was shown to be applicable to the creeping solid only when deformation takes place at a quasi-static strain rate.

Similar content being viewed by others

References

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

S. Bec, A. Tonck, J.M. Georges, E. Georges, and J.L. Loubet: Improvements in the indentation method with a surface force apparatus. Philos. Mag. A 74, 1061 (1996).

I.N. Sneddon: The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965).

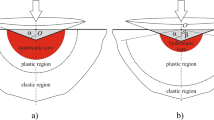

G. Hochstetter, A. Jimenez, J.P. Cano, and E. Felder: An attempt to determine the true stress-strain curves of amorphous polymers by nanoindentation. Tribol. Int. 36, 973 (2003).

J. Malzbender and G. de With: The use of the loading curve to assess soft coatings. Surf. Coat. Technol. 127, 266 (2000).

D. Tabor: The hardness of solids. Rev. Phys. Technol. 1, 145 (1970).

N. Fujisawa and M.V. Swain: Effect of unloading strain rate on the elastic modulus of a viscoelastic solid determined by nanoindentation. J. Mater. Res. 21, 708 (2006).

M.J. Mayo and W.D. Nix: A micro-indentation study of superplasticity in Pb, Sn, and Sn–38 wt% Pb. Acta Metall. 36, 2183 (1988).

B.N. Lucas, W.C. Oliver, G.M. Pharr, and J.L. Loubet: Time dependent deformation during indentation testing, in Thin Films: Stresses and Mechanical Properties VI, edited by W.M. Gerberich, H. Gao, J.E. Sundgren and S.P. Baker (Mater. Res. Soc. Symp. 436, Pittsburgh, PA, 1997), pp. 233–238.

Y.T. Cheng and C.M. Cheng: Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng. Rep. Rev. J. R44, 91 (2004).

P. Berthoud, C. G’Sell, and J.M. Hiver: Elastic-plastic indentation creep of glassy poly(methyl methacrylate) and polystyrene: characterization using uniaxial compression and indentation tests. J. Phys. D: Appl. Phys. 32, 2923 (1999).

G. Feng and A.H.W Ngan: Effects of creep and thermal drift on modulus measurement using depth-sensing indentation. J. Mater. Res. 17, 660 (2002).

B. Tang and A.H.W Ngan: Accurate measurement of tip-sample contact size during nanoindentation of viscoelastic materials. J. Mater. Res. 18, 1141 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fujisawa, N., Swain, M.V. On the indentation contact area of a creeping solid during constant-strain-rate loading by a sharp indenter. Journal of Materials Research 22, 893–899 (2007). https://doi.org/10.1557/jmr.2007.0135

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2007.0135