Abstract

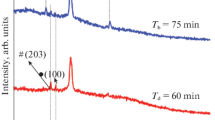

The film stress evolutions induced by the phase transformation of Sn/Ni(P) films during thermal treatment were investigated using an in situ measurement of wafer curvature by laser scanning. Apparently, tensile stress developed due to the layer-by-layer formation of Ni3Sn4 and Ni3P phases for Sn/Ni(11.7P) films, and a compressive stress evolved for Sn/Ni(3P) films, despite the same phase transformation. The molar volume mismatch and x-ray diffraction analyses before and after the reaction between Sn and Ni(P) films suggested that a compressive stress existed in the Ni3Sn4 layer while the Ni3P layer was under a tensile stress state. The apparent stress states (tensile or compressive) for overall thickness of the films formed by the layer-by-layer transformation in Sn/Ni(P) were determined by the competition between compressive stress related to Ni3Sn4 formation and tensile stress caused by Ni3P formation. The stress states were dependent upon the relative thickness of the product layers with varying P content.

Similar content being viewed by others

References

R.R. Tummala: Fundamentals of Microsystems Packaging (McGraw-Hill, New York, 2001), p. 361.

J.W. Jang, P.G. Kim, K.N. Tu, D.R. Frear, and P. Thompson: Solder reaction-assisted crystallization of electroless Ni–P under bump metallization in low cost flip chip technology. J. Appl. Phys. 85, 8456 (1999).

J.W. Jang, D.R. Frear, T.Y. Lee, and K.N. Tu: Morphology of interfacial reaction between lead-free solders and electroless Ni–P under bump metallization. J. Appl. Phys. 88, 6359 (2000).

C.Y. Lee and K.L. Lin: The interaction kinetics and compound formation between electroless Ni–P and solder. Thin Solid Films 249, 201 (1994).

B. Färber, E. Cadel, A. Menand, G. Schmitz, and R. Kirchheim: Phosphorus segregation in nanocrystalline Ni–3.6 at.%P alloy investigated with the tomographic atom probe (TAP). Acta Mater. 48, 789 (2000).

Y.C. Sohn, Yu. Jin, S.K. Kang, D.Y. Shih, and W.K. Choi: Effects of phosphorus content on the reaction of electroless Ni–P with Sn and crystallization of Ni–P. J. Electron. Mater. 33, 790 (2004).

P.L. Liu, Z. Xu, and J.K. Shang: Thermal stability of electroless-nickel/solder interface: Part A. Interfacial chemistry and microstructure. Metall. Mater. Trans. A 31, 2857 (2000).

S.K. Kang and V. Ramachandran: Growth kinetics of intermetallic phases at the liquid Sn and solid Ni interface. Scripta Metall. 14, 421 (1980).

D. Gur and M. Bamberger: Reactive isothermal solidification in the Ni–Sn system. Acta Mater. 46, 4917 (1998).

S. Bader, W. Gust, and H. Hieber: Rapid formation of intermetallic compounds by interdiffusion in the Cu-Sn and Ni-Sn systems. Acta Metall. Mater. 43, 329 (1995).

C.Y. Liu, C. Chen, A.K. Mal, and K.N. Tu: Direct correlation between mechanical failure and metallurgical reaction in flip chip solder joints. J. Appl. Phys. 85, 3882 (1999).

Y.D. Jeon, K.W. Paik, K.S. Bok, W.S. Choi, and C.L. Cho: Studies of electroless nickel under bump metallurgy-solder interfacial reactions and their effects on flip chip solder joint reliability. J. Electron. Mater. 31, 520 (2002).

Y. Guo, S.M. Kuo, and C. Zhang: Reliability evaluations of under bump metallurgy in two solder systems. IEEE Trans. Comp. Packag. Technol. 24, 655 (2001).

Y.C. Chan, P.L. Tu, C.W. Tang, K.C. Hung, and J.K.L Lai: Reliability studies of μBGA solder joints-effects of Ni–Sn intermetallic compound. IEEE Trans. Adv. Packag. 24, 25 (2001).

J.H.L Pang and D.Y.R Chong: Flip chip on board solder joint reliability analysis using 2-D and 3-D FEA models. IEEE Trans. Adv. Packag. 24, 499 (2001).

D. Mitchell, Y. Guo, and V. Sarihan: Methodology for studying the impact of intrinsic stress on the reliability of the electroless Ni UBM structure. IEEE Trans. Comp. Packag. Technol. 24, 667 (2001).

J.Y. Song and J. Yu: Residual stress measurements in electroless plated Ni–P films. Thin Solid Films 415, 167 (2002).

J.Y. Song, J. Yu, and T.Y. Lee: Analysis of phase transformation kinetics by intrinsic stress evolutions during the isothermal aging of amorphous Ni(P) and Sn/Ni(P) films. J. Mater. Res. 19, 1257 (2004).

P.P. Buaud, F.M. d’Heurle, E.A. Irene, B.K. Patnaik, and N.R. Parikh: In situ strain measurements during the formation of platinum silicide films. J. Vac. Sci. Technol. B 9, 2536 (1991).

O.B. Loopstra, E.R. van Snek, Th.H. de Keijser, and E.J. Mittemeijer: Model for stress and volume change of a thin film on a substrate upon annealing: application to amorphous Mo/Si multilayers. Phys. Rev. B: Condens. Matter 44, 13519 (1991).

J.F. Jongste, P.F.A Alkemade, G.C.A.M Janssen, and S. Radelaar: Kinetics of the formation of C49 TiSi2 from Ti-Si multilayers as observed by in situ stress measurements. J. Appl. Phys. 74, 3869 (1993).

G. Lucadamo and K. Barmak: Stress evolution in polycrystalline thin film reactions. Thin Solid Films 389, 8 (2001).

H.Th. Hesemann, P. Müllner, and E. Arzt: Stress and texture development during martensitic transformation in cobalt thin films. Scripta Mater. 44, 25 (2001).

J.Y. Song, J. Yu, and T.Y. Lee: Effects of reactive diffusion on stress evolution in Cu–Sn films. Scripta Mater. 51, 167 (2004).

Electroless Plating: Fundamentals and Applications, edited by O.G. Mallory and B.J. Hajdu (American Electroplaters and Surface Finishers Society, Orlando, FL, 1990).

K.N. Tu and R.D. Thompson: Kinetics of interfacial reaction in bimetallic Cu–Sn thin films. Acta Metall. 30, 947 (1982).

G.G. Stoney: The tension of metallic films deposited by electrolysis. Proc. R. Soc. London A 82, 172 (1909).

W.D. Nix: Mechanical properties of thin films. Metall. Trans. A 20, 2217 (1989).

The Mechanics of Solder Alloy Interconnects, edited by D.R. Frear, S.N. Burchett, H.S. Morgan and J.H. Lau (Van Nostrand Reinhold, New York, 1994), pp. 60.

T.P. Leervad Pedersen, J. Kalb, W.K. Njoroge, D. Wamwangi, M. Wuttig, and F. Spaepen: Mechanical stresses upon crystallization in phase change materials. Appl. Phys. Lett. 79, 3597 (2001).

J.A. Floro, S.J. Hearne, J.A. Hunter, P. Kotula, E. Chason, S.C. Seel, and C.V. Thompson: The dynamic competition between stress generation and relaxation mechanisms during coalescence of Volmer–Weber thin films. J. Appl. Phys. 89, 4886 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, J.Y., Yu, J. Effect of phosphorous content on phase transformation induced stress in Sn/Ni(P) thin films. Journal of Materials Research 21, 2261–2269 (2006). https://doi.org/10.1557/jmr.2006.0273

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2006.0273