Abstract

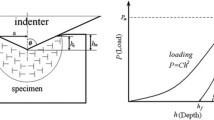

The work of indentation is investigated experimentally in this article. A method of using the elastic energy to extract the elastic modulus is proposed and verified. Two types of hardness related to the work of indentation are defined and examined: Hwtis defined as the total work required creating a unit volume of contact deformationand Hwp is defined as the plastic work required creating a unit volume of plastic deformation; experiments show that both hardness definitions are good choices for characterizing hardness. Several features that may provide significant insights in understanding indentation measurements are studied. These features mainly concern some scaling relationships in indentation measurements and the indentation size effects.

Similar content being viewed by others

References

N.A. Stilwell, D. Tabor: Elastic recovery of conical indentations. Proc. Phys. Soc. 78, 169 (1961).

M.C. Shaw The fundamental basis of the hardness test, in The Science of Hardness Testing and Its Research Applications, edited by J.H. Westbrook and H. Conrad (ASM Symposium, Metals Park, OH, 1971), p. 2.

A.M. Korsunsky, M.R. McGurk, S.J. Bull, T.F. Page: On the hardness of coated systems. Surf. Coat. Technol. 99, 171 (1998).

J.R. Tuck, A.M. Korsunsky, S.J. Bull, R.I. Davidson: On the application of the work-of-indentation approach to depth-sensing indentation experiments in coated systems. Surf. Coat. Technol. 137, 217 (2001).

D. Beegan, S. Chowdhury, M.T. Laugier: Work of indentation methods for determining copper film hardness. Surf. Coat. Technol. 192, 57 (2005).

M. Sakai: Energy principle of the indentation-induced inelastic surface deformation and hardness of brittle materials. Acta Met. Mater. 41, 1751 (1993).

M. Sakai: The Meyer hardness: A measure for plasticity? J. Mater. Res. 14, 3630 (1999).

K. Zeng, C.H. Chiu: An analysis of load-penetration curves from instrumented indentation. Acta Mater. 49, 3539 (2001).

S.V. Hainsworth, H.W. Chandler, T.F. Page: Analysis of nanoindentation load-displacement loading curves. J. Mater. Res. 11, 1987 (1996).

G.M. Pharr, A. Bolshakov: Understanding nanoindentation unloading curves. J. Mater. Res. 17, 2660 (2002).

H. Men, Z.Q. Hu, J. Xu: Bulk metallic glass formation in the Mg–Cu–Zn–Y system. Scripta Mater. 46, 699 (2002).

W.C. Oliver, G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

W.C. Oliver, G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

B.N. Lucas, W.C. Oliver: Indentation power-law creep of high-purity indium. Metall. Mater. Trans. A 30A, 601 (1999).

J. Malzbender, G. de With, J. Toonderden: The P-h2 relationship in indentation. J. Mater. Res. 15, 1209 (2000).

A. Bolshakov, G.M. Pharr: Influence of pileup on the measurement of mechanical properties by load and depth-sensing indentation techniques. J. Mater. Res. 13, 1049 (1998).

W. Ni, Y.T. Cheng: Modeling conical indentation in homogeneous materials and in hard films on soft substrates. J. Mater. Res. 20, 521 (2005).

Y.T. Cheng, C.M. Cheng: Scaling, dimensional analysis, and indentation measurements. Mater. Sci. Eng. R 44, 91 (2004).

M.A. Maneiro Garrido, J. Rodriguez: Pile-up effect on nanoindentation tests with spherical-conical tips. Scripta Mater. 52, 593 (2005).

Y. Wang, D. Raabe, C. Kluber, F. Roters: Orientation dependence of nanoindentation pile-up patterns and of nanoindentation microtextures in copper single crystals. Acta Mater. 52, 2229 (2004).

P.B. Coates, J.W. Andrews: A precise determination of the freezing point of copper. J. Phys. F: Met. Phys. 8, 277 (1978).

http://environmentalchemistry.com/yogi/periodic/Cu.html. Last accessed July 30, 2005.

I.N. Sneddon: The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 3, 47 (1965).

S.W. Youn, C.G. Kang: FEA study on nanodeformation behaviors of amorphous silicon and borosilicate considering tip geometry for pit array fabrication. Mater. Sci. Eng. 390, 233 (2005).

K.W. Xu, G.L. Hou, B.C. Hendrix, J.W. He, Y. Sun, S. Zheng, A. Bloyce, T. Bell: Prediction of nanoindentation hardness profile from a load-displacement curve. J. Mater. Res. 13, 3519 (1998).

J. Mencik, M.V. Swain: Micro-indentation tests with pointed indenters. Mater. Forum 18, 277 (1994).

Y.T. Cheng, Z. Li, C.M. Cheng: Scaling relationships for indentation measurements. Philos. Mag. A 82, 1821 (2002).

W.D. Nix, H. Gao: Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 46, 411 (1998).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tan, M. A study of indentation work in homogeneous materials. Journal of Materials Research 21, 1363–1374 (2006). https://doi.org/10.1557/jmr.2006.0168

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2006.0168