Abstract

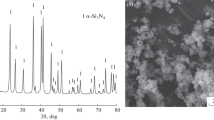

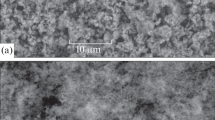

Sintering of Si3N4 compounds requires additives that promote densification through the dissolution-precipitation mechanism in liquid phase sintering. The sintering of the Si3N4 with the SiO2-Y2O3-Al2O3 system has been extensively studied. Nevertheless, because SiO2 depends on the natural amount on the Si3N4 surface, little has been studied about SiO2 control. A pre-sintering treatment can increase the content of SiO2 through controlled oxidation of Si3N4. In this work the effect of the additive content on the densification of Si3N4 composite ceramics was evaluated. For this purpose, powder mixtures of Si3N4, Y2O3 and Al2O3 were prepared. The Y2O3 and Al2O3 ratio were modified in percentages of 4, 8 and 12% by weight. The mixtures were compacted and pre-sintered at 1300°C for 1 hour. Then, these were sintered at 1450°C for two hours. The samples were characterized by scanning electron microscopy (SEM) and X-ray diffraction (XRD). Results showed that during pre-sintering, the Y5(SiO4)3N phase is formed; then, it's subsequently oxidized at the sintering stage. A second phase identified as Y3Al5O12 was found in samples with higher proportions of Al2O3. Composition and quantity of the observed phases depend of Y2O3 and Al2O3 proportion in the added additive.

Similar content being viewed by others

References

J.L Huang, {etet al.}, Effects of two-step sintering on the Microstructure of Si3N4, Ceram Int, 22 131–136 (1996).

W. Chen, Lv Zhenglin, D. Gao, X. Ai, Study on preparation and physical mechanical properties of Si3N4 composite ceramics, MATEC Web of Conferences 22, 05019 (2015).

Andrievskii R. A., Silicon nitride: synthesis and properties, Russ chem rev+ 64 (4) 291–308 (1995).

Cárdenas L. C., Effect of quantity of additive during sintering.sps, joining and oxidation of silicon nitride, Phd. thesis, Instituto de investigaciones metalúrgicas, UMSNH, Morelia (2013).

J.L. Xue, {etet al.}, Influence of planetary High-Energy Ball Milling on microstructure and mechanical Properties of silicon nitride ceramics, J. Am. Ceram. Soc., 88 [5 ]1323–1326 (2005).

J.C. Almeida, {etet al.}, Presureless Sintering of silicon nitride with additives of the Y2O3, Al2O3, SiO2 system, Mat Sci eng, A109 395–400 (1989).

W. Xu, {etet al.}, Effects of sintering additives on mechanical properties and microestructure of Si3N4, ceramics by microwave sintering J. Mate. Sci. Eng. A., 684:127–134 (2017).

B.J. McEntire, {etet al.}, processing and characterization of silicon nitride bioceramics. Bioceram Dev Appl 6:1 (2016).

A. Ziegler and M. Mc Naney, On the effect of local grain boundary chemistry on the macroscopic mechanical properties of a high-purity Y2O3-Al2O3-containing silicon nitride ceramic: role of oxygen, J. Am. Ceram. Soc., 88 [7 ] 1900–1908 (2005).

S. Wada, Control of instability of Si3N4 during Pressureless sintering, J Ceram Soc Jpn, 109 [10 ] 803–808 (2001).

T. Honma, Y. Ukyo, Sintering process of Si3N4 with Y2O3 and Al2O3 as sintering additives, Journal of Material Sciences letter 18, 735–737 (1999)

J. F Yang, T. Ohji, Influence of yttria-Alumina content on sintering behavior and microstructure of silicon nitride ceramics, J. Am. Ceram. Soc. 83 [8 ] 2094–96 (2000).

R. R. Wills, {etet al.}, Stability of the silicon yttrium oxynitrides, Jam ceram soc-Discission and notes, Vol. 59, No. 5-6, P. 269 (1976).

Vuckovic, B. Matovic, S. Boskovic, Influence of additive type on densification and phase transformation of seeded Si3N4, Materials Science Forum, ISSN: 1662-9752, Vol. 494, pp 429–434 (2005)

E.F. Bertaut, J. Mareschal, C.R. Hebd, Seances Acad. Ci., 44, P. 867 (1963).

R.J. Lumby, E. Butler, M.H. Lewis, Lucas Syalons: composition, structure, properties and uses; in “Progress in Nitrogen Ceramics”, Proceeding of the NATO Advanced Study Institute on Nitrogen Ceramics, ISBN-13:978-94-009-6853-0, UK, (1981).

S. Wada, Control of instability of Si3N4 during Pressureless sintering, J Ceram Soc Jpn, 109 [10 ] 803–808 (2001).

W.D Kingery, Densificación during sintering in the presence of a liquid phase. I. Theory, J. Appl. Phys. 30, 301, (1959).

J. Svoboda, H. Riedel, R. Gaebel, A model for ñiquid phase sintering, Acta Mater. Vol 44, No. 8, pp.3215–3226, (1996).

H. Mao, M. Selleby, B. Sundman, Phase equilibria and thermodynamics in the Al2O3-SiO2 System- Modeling of mullite and liquid, J, Am. Ceram. Soc., 88, [9 ] 2544–2551 (2005).

K. H. Jack, Nitrogen ceramics, Trans. J. Brit. Ceram. Soc., 72, [8 ] 376–84 (1973).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Leon-Geronimo, A., Miranda-Hernandez, Q., Figueroa-Vargas, I. et al. Effect of the additive content on the sintering of pre-sintered Si3N4 composite.. MRS Advances 5, 3103–3111 (2020). https://doi.org/10.1557/adv.2020.427

Published:

Issue Date:

DOI: https://doi.org/10.1557/adv.2020.427