Abstract

Boron nitride nanotubes (BNNTs) are emerging nanomaterials with analogous structures and similarly impressive mechanical properties to carbon nanotubes (CNTs), but unique chemistry and complimentary multifunctional properties, including higher thermal stability, electrical insulation, optical transparency, neutron absorption capability, and piezoelectricity. Over the past decade, advances in synthesis have made BNNTs more broadly accessible to the nanomaterials and other research communities, removing a major barrier to their utilization and research. Therefore, the field is poised to grow rapidly and see the emergence of BNNT applications ranging from electronics to aerospace materials. A key challenge, that is being gradually overcome, is the development of manufacturing processes to make “neat” BNNT materials. This overview highlights the history and current status of the field, providing both an introduction to this Focus Issue—BNNTs: Synthesis to Applications—as well as a perspective on advances, challenges, and opportunities for this emerging material.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

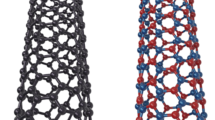

The history of boron nitride nanotubes (BNNTs) largely began in the mid-1990s with the first experimental realization of the nanotube form of BN in 1995 [1], following close on the heels of their theoretical prediction a year earlier [2]. That groundbreaking work, which launched the present field of BNNTs, built on the foundation of carbon nanotubes (CNTs) [3] and the structural similarities between the C–C and B–N bonds. As shown in Fig. 1, BNNTs and individual hexagonal-BN (h-BN) sheets have structures analogous to CNTs and graphene. This structure and the similarly strong B–N bonds give BNNTs comparably impressive mechanical properties to CNTs; however, the different composition and partially ionic bonding result in a unique and complementary suite of functional properties in comparison to CNTs (Table 1), including electrical insulation, transparency to visible light, high thermal stability, piezoelectricity, and neutron absorption.

Ball-and-stick structural models for a single-walled BNNT and an h-BN sheet (bottom), along with a single-walled CNT and a graphene sheet (top). The alternating B and N atoms, shown in red and green, respectively, form analogous structures to those formed with C atoms, shown in black. These models, which show zigzag (10, 0) nanotubes, were generated using Nanotube Modeler [19].

The uniqueness of BNNTs stimulated early excitement and experimental activities, including fundamental physics studies and small-scale chemistry research. However, while the CNT field grew rapidly over the same time period, BNNTs received limited attention (Fig. 2). Notably [(Fig. 2(a)], the field grew slowly for the first half of its existence (i.e., until BNNTs reached their mid-to-late teen years) because of the relative difficulty of synthesizing BNNTs; hence, outside of particular locations (e.g., References [1, 4,5,6,7,8,9]), BNNTs were not widely investigated. Change started in the 2010s, with the advent of synthesis approaches that could produce high-quality BNNTs, including scalable methods with gram-to-kilogram/day production capacity [10], and most recently the emergence of a growing list of commercial BNNT materials. This has led to increasing activity with a growing numbers of researchers and publications and mounting commercial activity. Now, BNNTs are a true emerging material that is accessible and available to a broad R&D community and is starting to generate commercial applications.

The complementary nature of BNNT properties in comparison to carbon nanomaterials, including CNTs, which for some time have been produced at worldwide annual rates measured in kilotons [11], can be expected to drive the current phase of the BNNT field. That is particularly true for early-stage applications outside of the lab environment. While the challenge of accessing BNNT materials for research purposes has been overcome, commercial BNNTs remain costly, making CNTs (or even graphene) advantageous in cases where either type of nanomaterial can perform well—particularly so when the nanotubes are used as inclusions to improve the strength or thermal conductivity of a host material. Yet, the functional properties of BNNTs impart clear advantages or could even be the only options where carbon nanomaterials are unsuitable, including cases where electrical insulation, high thermo-oxidative stability, or transparency to visible light are essential. BNNTs can also be advantageous over CNTs and graphene nanomaterials in that they exhibit a piezoelectric effect; furthermore, boron offers a high neutron absorption cross-section, which is absent in CNTs. Therefore, in combination with CNTs, BNNTs contribute to an expanded set of complementary, multifunctional nanotube materials beyond what can be achieved with carbon nanomaterials. For this potential to materialize on a larger scale, scientific understanding will be needed on what subset of BNNTs may produce the advantages predicated on the properties of their idealized structures. Lack of clarity on structure–property relations was a main cause of the near-collapse of CNTs in the early 2010s [12, 13]. The application potential had been hyped based on the properties of structurally perfect single and few-walled CNTs, but initial scale-up efforts produced highly defective materials that had relatively small advantages over carbon black and carbon nanofiber fillers and hence failed to get commercial traction. Clarifying structure–property relations before embarking on extensive commercial scale-up will allow a more efficient use of resources and, likely, will mitigate or even prevent a hype-disillusionment cycle for BNNTs.

For these reasons—the emergence of BNNT manufacturing and the associated increases in material availability and researcher and commercial activity—now is a pertinent time for this Focus Issue—BNNTs: Synthesis to Applications. BNNTs have been the subject of a range of review articles, including several in recent years [14,15,16,17,18], and exciting advances range from BNNT synthesis, to novel chemistry, to applied investigations in areas from space to medicine. The intent of this overview is not to duplicate existing and comprehensive reviews. Rather, this article serves as an introduction to the Focus Issue, highlighting recent advances to offer a current perspective and future outlook for the growing field of BNNTs.

BNNT highlights

In this section, we highlight recent progress beginning with (1) advances in synthesis and manufacturing, which have enabled the acceleration of the BNNT field in the past decade and followed by (2) BNNT chemistry, (3) BNNT sheets and fibers, (4) BNNT-reinforced composites, (5) biological and medical, and (6) other novel applications.

Synthesis and manufacturing

Despite numerous efforts since their first synthesis in 1995, progress in the synthesis of high-quality BNNTs has been much slower compared to CNTs and still remains a significant challenge. The main challenges are lack of reliable BN sources that are processable at low temperatures, and controlled incorporation of B and N atoms into the hexagonal lattice. Inspired by the synthesis of CNTs, both low- (< 2000 K) and high-temperature methods (> 4000 K) have been extensively investigated for the production of BNNTs, and it is only recently that we have witnessed the advent of large-scale synthesis methods that led to successful commercialization [10, 20]. Table 2 summarizes physico-chemical properties of several BNNT materials that are currently available commercially.

The high-temperature processes include arc discharge, laser vaporization, and thermal plasma jet methods. In these approaches, a direct BN source such as elemental B or h-BN powders can be employed and vaporized (e.g., via high-temperature plasma) to produce BNNT seeds along with effective BN precursors. BNNTs are typically grown from boron droplets (i.e., BNNT seeds) via in-flight reactions with N-containing species without metal catalysts. The inherent slow kinetics in this re-nitridation process has been largely addressed either by employing high pressure [22, 23] or using hydrogen as a gas-phase catalyst [24]. A high production rate approaching 20 g/h has been achieved and led to successful commercialization of high-quality BNNTs with small diameters (∼5 nm) and few walls (3–4 walls). A production rate of ~ 22 g/h is reported in this issue using a DC plasma process with hydrogen gas injected to form a vortex, which increases residence time in addition to forming intermediates [25]. The average BNNT diameter varied from ~ 10 nm to almost 20 nm in different regions of the reactor, with potential to adjust residence time to vary diameter. However, BNNTs produced in high-temperature processes are still accompanied by the production of BN impurities (e.g., a-BN, BN shells, BN flakes), necessitating additional post-purification processes for their practical applications [26,27,28]. In this Focus Issue, Alston and colleagues [29] provide a comprehensive review of BNNT purification and show that improvements in both purification and purity assessment are key challenges in relation to broader use of high-temperature-produced BNNTs. A recent study has employed both experimental and numerical approaches for a mechanistic understanding of BN impurity formation in a high-temperature plasma jet process and suggested that the flow structure of the plasma jet (such as turbulence) plays a key role in the formation of BN impurities [30]. Very recently, it was reported that BN radicals can be effectively produced from the controlled decomposition of ammonia borane in a laser ablation process. BNNTs were grown from the BN radicals via homogeneous nucleation and thus resulted in a minimal formation of B impurities [31].

The low-temperature approach includes CVD and ball milling processes. Owing to their low processing temperatures, typical precursors include boric acid and melamine, boron powders and metal oxides, and gaseous boron-containing feedstock. The CVD process produces BNNTs with fewer impurities; however, low yield of around 1 g/h is an issue to be addressed for successful commercialization. The ball milling process has demonstrated a potential for large-scale production up to kg-scale, while, in that case, low quality of BNNTs and formation of impurities still remain challenges. Both methods usually produce BNNTs larger than 20 nm. Similar to CNT synthesis, the CVD method presents excellent opportunities for the controlled synthesis of BNNTs, including the production of vertically aligned BNNTs (VA-BNNTs). A recent review paper focused on CVD synthesis including the effect of precursors, catalysts, and gases in the CVD process [17]. Although BNNT growth models are critical for catalyst design, their nucleation mechanism was less studied and still remains unknown. A recent non-equilibrium molecular dynamics (MD) simulation revealed how BNNT cap structures are created in a Ni-catalyzed CVD process [32]. Notably, CNT synthesis was scaled up via catalyzed CVD (floating catalyst for high-quality CNTs, supported catalyst for lower-quality material); hence, improvements in BNNT CVD synthesis may be the highest payoff pathway to scale, even though this route presently lags high-temperature synthesis in terms of productivity.

While production of high-quality BNNTs with the focus on increased yield and purity has been the main interest in the past decade, targeted syntheses of BNNTs with specialized features provide a third challenge for BNNT synthesis (Fig. 3). For example, VA-BNNTs forests have been manufactured using VA-CNTs as a template [33, 34], which provides new opportunities in a wide range of applications, including electronics, nanocomposites, and thermal management. The synthesis of single-walled CNTs (SWCNTs) was quickly realized at reasonable scales (e.g., in Smalley’s Tubes@Rice effort); conversely, such synthesis has been achieved only in limited and small-scale reports for BNNTs (e.g., Reference [35]). Notably, SWCNTs were expected to have dramatically different electrical properties (metallic to semiconducting) depending on their diameter and chirality; whereas such properties are critical for electronics, their importance was over-estimated for the area of macroscopic materials, where aspect ratio and crystallinity proved more important to attain high-level macroscopic properties [36]. In this respect, SWCNTs and few-walled CNTs proved superior to their larger diameter, multiwalled counterparts because of their inherently higher degree of crystalline order. The optical and electrical properties of SW-BNNTs do not depend appreciably on their structure; hence there is no anticipated difference between SW-BNNTs and their few-walled counterparts. However, SW-BNNTs may also have higher crystallinity because defects cannot lock in place by chemical bonding between walls, which would be advantageous in macroscale structures. Moreover, control of electronic/optical/adsorption properties of BNNTs by doping or creating heterostructure interfaces is of high interest for electronic or energy applications [37, 38]. Hybrid NTs such as BNNT@CNT have been demonstrated as one-dimensional van der Waals heterostructures [39, 40], and their properties have been investigated experimentally and by first-principles modeling [41,42,43].

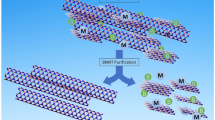

BNNT chemistry and functionalization

Chemical processing and modification are essential to utilize BNNTs in many applications. While the B–N bond is isoelectronic with C–C, allowing the formation of analogous phases such as h-BN and BNNTs, the difference in composition and the partially ionic nature of the bonding means that BNNT chemistry differs from that developed for CNTs. Nonetheless, approaches similar to those used for CNTs have been investigated to functionalize BNNTs, including surfactants, polymer wrapping, covalent functionalization, and others (Fig. 4), and several reviews (e.g., References [20, 44,45,46]) have addressed BNNT functionalization. Early reports used polymer wrapping [47] or covalent functionalization of BNNT edges and defects [48]. Among later reports, reductive chemistry has been shown to facilitate covalent functionalization [49, 50]. The electron-deficient boron atoms can also act as Lewis acids. For example, in this issue, BNNTs are covalently functionalized using sonolysis of a primary alcohol to form radicals that can covalently attach to the boron atoms of BNNTs [51]. Of particular importance across the BNNT field are (1) the purification of raw BNNT materials, which contain different impurities depending on the synthesis methods, and (2) dispersion of BNNTs, which is often the critical step for the integration of BNNTs in composites. While boron impurities can be removed following chemical purification (e.g., via oxidation), other BN nanomaterials different from BNNTs are more difficult to remove due to the similarity of chemical bonds and composition. Their purification is generally based on selective dispersion or solubility of either the BNNTs or impurities. For example, the preferential solubility of BNNTs in chlorosulfonic acid has been employed to purify BNNTs to produce films and aerogels [52]. In this issue, advances in BNNT purification and dispersion are addressed in comprehensive reviews by Maselugbo et al. [29] and Smith McWilliams et al. [46], respectively, and MD simulation is employed to study interfacial interactions of poly(4-vinylpyridine) with BNNTs and h-BN with the goal to understand and improve purification of BNNTs by selective dispersion [53].

Approaches for chemical modification of BNNTs. Reprinted by permission from Springer Nature, Journal of Materials Research, Reference [40], copyright 2022.

Both purification and dispersion processes are essential to producing BNNT fibers in liquid spinning methods, and the properties of nanotube assemblies and composites typically correlate with the purity and dispersion quality. Additionally, due to their ionic character, multiwalled BNNTs exhibit higher resistance to pull out of inner walls [54] and BNNTs exhibit stronger interactions with common polymers [55, 56], both of which give BNNTs an inherent advantage over CNTs in the area of polymer nanocomposites.

BNNT sheets and fibers

Similar to CNTs, direct spinning of BNNT fibers during the synthesis process can find many important applications [57]. To facilitate in-flight alignment and coalescence of BNNTs from BNNT aerogels the formation of impurities must be minimized. In a recent study, BNNT fibers were formed spontaneously from the laser ablation of an ammonia borane target because of the absence of amorphous boron impurities [31]. BNNT yarns and tapes have also been collected during a CVD synthesis [58], which can provide for continuously drawn yarns or sheets. Supported thin films also have been synthesized directly by patterning the catalyst for CVD synthesis [59] or painting using a boron ink precursor [60]. Along with assembly during synthesis, BNNTs have been assembled into fibers, yarns, or sheets through post-synthesis processing (Fig. 5). This includes twisting or compressing as-produced BNNT bundles or mats, and filtration-based methods to produce nonwoven nanotube sheets commonly called buckypapers. Aligned BNNT films were created through surface coating using high concentration DNA-wrapped BNNTs that form an ordered phase during drying [61]. Most recently, the first BNNT liquid crystal was reported, using high-quality BNNTs in chlorosulfonic acid, and the nematic liquid crystal domains were processed into aligned films and fibers [62]. In addition to direct collection and liquid spinning, drawing and spinning of yarns from vertically aligned CNT arrays or forests have been used to produce CNT yarns [63]; however, there have yet to be any analogous reports showing drawable/spinnable BNNT arrays. The mechanical properties reported for BNNT assemblies to date are modest compared to the leading CNT yarn and sheet materials, but compare well to early reports for CNT fibers or to CNT buckypapers made from dispersion of similar aspect ratio CNTs. The properties of these BNNT assemblies already show promise for producing BNNT composites with high BNNT contents [64, 65] and the properties of the BNNT assemblies themselves can be expected to improve significantly as the synthesis and processing methods improve, including achieving high-quality BNNTs with higher purity and longer length. In this issue, high-resolution electron microscopy is employed to study the effect of defects in purified BNNTs on alignment to form the ordered domains necessary to produce ordered assemblies by liquid-phase processing [66] Additionally, MD simulations of BN nanoribbons indicate that BNNT strength is strongly influenced by the location and orientation of preexisting cracks [67]. Such defects could reduce the strength or effective length of BNNTs, which impact performance of the assembly. BNNT production costs also will become important once these macroscopic materials attain their potential properties—these are the most cost-sensitive applications because BNNTs are used in bulk rather than as a low-concentration dispersed agent.

Examples of BNNT assemblies: (a) first BNNT yarn produced by finger twisting of as-produced BNNTs (used with permission of IOP Science, from Ref. [22]; permission conveyed through Copyright Clearance Center, Inc.), (b) BNNT buckypaper and BNNT paper airplane in a flame (Reproduced from Ref. [1] with permission from the Royal Society of Chemistry), (c) BNNT film patterned using boron ink (used with permission of Royal Society of Chemistry, from Ref. [60]; permission conveyed through Copyright Clearance Center, Inc.), (d) collection of BNNT fiber during laser synthesis (reproduced and adapted, with permission, from Ref. [31] under a Creative Commons Licence: http://creativecommons.org/licenses/by/4.0/), (e) aligned BNNT-DNA film (reprinted and adapted with permission from Ref. [61]. Copyright 2019 American Chemical Society), and (f) BNNT fiber produced from chlorosulfonic acid liquid crystal BNNT solution (reproduced and adapted, with permission, from Ref. [62] under a Creative Commons Licence: http://creativecommons.org/licenses/by/4.0/).

BNNT-reinforced composites

The advances in BNNT manufacturing leading to broader availability of gram-scale quantities of BNNTs achieved over the past decade, along with those for the production of BNNT assemblies (in particular fibers, films, and buckypapers) and for chemically purified and modified BNNTs, have enabled increased activity in BNNT composites. BNNT composites are addressed in several recent reviews [15, 17]. Although the stronger interaction between BNNTs and polymers might ultimately make BNNTs the preferred nanotube for the mechanical reinforcement of polymers, CNTs are much more advanced in terms of synthesis, functionalization, and composite integration. Therefore, the most promising cases for BNNT composites in the short-to-medium term are those where the desired multifunctional properties make BNNTs advantageous or even render carbon-based nanomaterials unsuitable (Table 3).

In the case of multifunctional polymer nanocomposites, BNNTs have been shown to enhance the piezoelectric response of both piezoelectric and non-piezoelectric polymers [69,70,71,72]. Additionally, the optical properties of BNNTs allow for nanotube-reinforced polymers that remain highly transparent at modest thickness [73, 74]. This is of particular relevance for transparent coatings or adhesives, which are not achievable with CNTs due to their high absorption across the visible spectrum. Although not yet shown to offer transparent composites at bulk thicknesses, BNNT optical properties are also favorable for nanotube-reinforced dental restorative materials, where color is important to the application and the potential bioactivity and non-cytotoxicity of BNNTs may also be advantageous [75]. BNNT–polymer composites are promising for substrates and packaging in particular for high power electronics where the heat dissipation challenge is increased and high electrical insulation is also needed. Composites with 10–40-wt% BNNTs have been shown to have thermal conductivities 20 × higher or more than typical polymers [76,77,78]. Relatively high loading as well as preferential alignment of BNNTs are beneficial for both mechanical and multifunctional properties. In recent years, BNNT–polymer composites have been made from BNNT papers/sheets [64, 65, 79] as well as BNNT-–composite fibers through composite fiber making approaches, including wet spinning and electrospinning [80,81,82,83,84]. BNNT-PAN fibers have also been converted to BNNT-enhanced carbon fiber through pyrolysis [83, 84]. While their functional properties provide nearer-term application potential, ultimately mechanical properties of BNNT-reinforced composites will also be important. In addition to exhibiting stronger interaction with polymers in comparison to CNTs [55, 56], new MD simulations in this issue show that BNNTs are expected to interact more strongly with bismaleimide (BMI) resins—an important case for high-performance composite materials—than with either epoxy or cyanate ester resins [85]. The functional properties of BNNTs also favor their application in extreme environments and use in high-temperature manufacturing processes. This includes resistance to space-based radiation and the ability to provide mass-efficient neutron shielding [69, 86,87,88,89]. Additionally, the high thermal stability of BNNTs enables high-temperature nanocomposites [90], including high application temperature and/or high fabrication temperatures needed for many metals or ceramic matrix composites. Among other examples, BNNTs have been shown to reinforce ceramics, including reducing brittle fracture and increasing the toughness of aluminum oxide ceramics produced by spark plasma sintering [91], and to modify the dielectric properties of polymer-derived ceramics for potential application as electromagnetic transparent materials in harsh conditions [92]. BNNTs are also promising for metal composites, including aluminum (e.g., References [93, 94]) and titanium (e.g., Reference [95]), the latter showing potential for improved neutron shielding and wear for lunar applications [89]. Recently, BNNTs have also been used in metal additive manufacturing, where incorporation of BNNT-decorated titanium alloy powders were employed with a laser-additive manufacturing system to produce BNNT-reinforced alloys [96].

Biological and medical

Similarly to CNTs, BNNTs have shown great promise for biomedical applications. More than a decade ago, Ciofani et al. reported the first studies on the cytocompatibility of BNNTs with human neuroblastoma cells (SH-SY5Y) [97]. These BNNTs were dispersed in water using polyethyleneimine and showed good viability up to concentrations of 5 μg/mL of nanotubes. After this, a variety of studies have been performed in cells as discussed in greater detail in this issue by Kodali et al. [98] The presence of impurities, BNNT concentration, and exposure time have a remarkable effect on the viability of cells when exposed to this nanomaterial.

BNNTs have been explored also for drug delivery. Having a large surface area, these nanomaterials are the ideal vehicles for delivering molecules for medical treatments. For example, BNNTs coated with amine-modified silica have been used to deliver doxorubicin to prostate cells, increasing the efficiency of drug internalization and the efficacy of killing cells [99]. Alternatively, doxorubicin adsorbed on bare BNNTs shows a pH-dependent release and increases toxicity for HeLa and HUVECs cells when conjugated to a cancer-targeting molecule (folate). Other drugs such as tamoxifen and paclitaxel drugs were loaded in BNNTs coated with Pluronic F127 and tested against MCF-7 cells and A549, respectively, showing lower cell viability than the free drug [100]. In addition, taking advantage of the 10B naturally present in BNNTs, Nakamura et al. have used boron neutron capture therapy to kill B16 melanoma cells [101]. Other molecules have been used to cover BNNTs including single-stranded DNA [102], Plasmids [103], and NaGdF4:Eu [104], for a variety of therapeutic and diagnostic applications.

The effect of BNNTs in tissue and organisms has also been studied. BNNTs composites with hydroxyapatite have improved elastic modulus, wear resistance, and osteogenesis with applications to orthopedic implants [105, 106]. The effect of BNNTs has also been studied in organisms. For example, the interaction of BNNTs with planarians have been studied showing no adverse effects [107]. Research in mice using 99mTc-labeled BNNTs showed that BNNTs accumulate in the liver, spleen, and gut at 30-min post-injection and appear as well as in the kidneys and bladder; however, after 1 and 4 h, images show a decrease of BNNTs due to clearance [108]. A thorough review on the toxicity of BNNTs in a variety of models is provided in this issue by Kodali et al. [98].

Other novel applications

The BNNT community continues to explore and develop new applications and what can be captured in the scope of this brief overview only scratches the surface. Hydrogen storage was first investigated relatively early in the history of BNNTs [109], and there remains interest both in the storage of hydrogen and also in the addition of hydrogen to BNNTs to increase their neutron shielding capability. BNNTs also are being applied in the field of electronics, with BNNTs modified with quantum dots [110], encapsulating atomic chains [111], and other variations recently explored in nanoelectronics as reviewed in this issue by Zhang et al. [38]. BNNTs have also shown to be viable low-k dielectric materials [112] and, in printed electronics, BNNTs were recently shown to improve the performance of photosintered metal ink traces for through improved thermal management [113]. BNNTs also have been reported to improve the stability of encapsulated dye molecules [114] and to be useful as carriers for high-brightness fluorophores wherein organizing dye molecules on the surface of BNNTs led to a dramatic increase in fluorescence [38], both of which could improve dye performance and imaging in biological applications. BNNTs, in particular in BNNT films/sheet form, can also be used as membranes, such as for water filtration [16, 18], and the high-temperature stability of BNNTs can enable efficient re-use of membranes [115]. Alternatively, BNNTs have also been coated onto polymer membranes and shown potential to improve the thermal stability of separator membranes for safer lithium ion and lithium–sulfur batteries [116, 117], representing a developing application case of BNNTs in the energy field.

Conclusions and outlook

One could simplify BNNT history to-date by grouping it into two phases. The first phase (ca. 1995 to ~ 2010) was supply-limited and marked by a focus on synthesis methods, fundamental properties, theoretical studies, and small-scale chemistry. The second phase (~ 2010 to present day) has been marked by the emergence of larger-scale synthesis and commercial BNNT materials, starting a shift toward a demand-limited scenario with the availability of sufficient quantities of BNNTs (from a lab research perspective) to engage more researchers—including academic and industry laboratories not engaged in BNNT synthesis—and to enable increased activity in areas, such as BNNT purification and BNNT composites, where larger quantities of raw BNNT materials (e.g., > 1 g) are critical. To put this into perspective, CNTs attained the second phase starting in the mid-1990s, with Smalley’s synthesis of laser-oven SWCNTs [118, 119] and the subsequent establishment of Tubes@Rice [120], which supplied the academic community with much of the initial studies on high-quality CNTs.

Mars-shot?

While considering how the BNNT field will advance over its next 10- to 15-year period, it is tempting to speculate about a Moon-shot goal (or Mars-shot!), such as ultrastrong lightweight high-temperature composites. Such a BNNT composite would be revolutionary for multifunctional space structures; in fact, NASA continues to be a key leader in the BNNT field due in part to the unique advantages of BNNTs for space applications [121], including for radiation shielding on long-duration missions (e.g., Lunar Gateway and Mars missions) and for extreme temperature cases (e.g., re-entry and for hypersonic vehicles). However, ultrastrong nanocomposite space structures based on much more developed CNT materials remain a technological challenge and an active area of research today [122, 123]. BNNTs will certainly benefit from this work that is now at the frontier of the CNT composites field. Drawing additional parallels to the progress of CNTs, it is more likely that evolutionary applications (e.g., the use of CNT powders as a better filler or additive for conductive plastics and batteries) will spur the increased demand for BNNTs needed to reach economies of scale. An obvious leading candidate is thermally conductive plastics for electronics packaging, which also nicely parallels the use of CNTs electrically conductive plastics. Thermal conductivities in the range of a few to 20 W/m/K are lower than typical electrical conductors but would be transformative in electrically insulating plastics, particularly in high power electronics with high heat production rates and unmet needs for adequate electrical insulation. Reinforcement of commonly used metals would also spur large demand for BNNTs. Displacing even a tiny fraction of the aluminum alloy market with BNNT-reinforced alloys would require BNNT quantities in excess of current worldwide production capacity. Successes in these area would greatly increase the demand for BNNTs. In the medium term, the use of BNNTs as reinforcement in metal additive manufacturing (3D printing) is more likely to find niche applications. Even with recent advances in commercial BNNTs, worldwide production of BNNTs is still low and the materials are high cost. Applications where BNNT composites provide useful and unique advantages are likely to drive the increase in production volume needed to achieve viable cost points.

Particle to article

Again drawing on the CNT field, where pre-formed assemblies of CNTs (i.e., buckypaper, films, tapes, and yarns) have enabled some of the highest performance CNT materials, the BNNT field is beginning to see more examples and improved properties for BNNT sheets and fibers. As for CNTs, macroscopic articles made of BNNTs (e.g., fibers, sheets or arrays) simplify the introduction into material manufacturing chains (relative to BNNT particles or powders) and can achieve high content of BNNTs and BNNT alignment in composite materials, which is essential to better leverage their structural and functional properties. Much like in synthesis, the BNNT field lags by about 15–20 years the CNT area, where macroscopic CNT fibers were attained in the early 2000s [124] and properties were achieved a decade later [125]. Early reports of BNNT fibers were published in the past year [31, 62]; the development of structure–processing–property relationships for BNNT fibers is now critical. As for CNTs, it will rely on improvements in BNNT purity, quality, and availability. Such anticipated improvements in BNNT assemblies will translate to broader application development, including new and improved BNNT composites with high contents of aligned BNNTs.

Understanding and control

The recent advances in BNNT development and applications are built on ~ 25 years of foundational studies on BNNT growth, chemistry, and properties. Fundamental research remains essential to improve understanding and control of BNNTs. Improved in situ assessment and diagnostics are likely to impact BNNT synthesis and manufacturing, including the less developed areas of BNNT fibers, BNNT arrays, and doped BNNTs. Spinnable arrays, which are highly sensitive to synthesis conditions but are now fairly well established for the case of CNTs [126], have yet to be reported for BNNTs. There is also a need for more control in terms of scalable and green methods for chemical purification and functionalization, as well as better methods to characterize BNNTs.

Standardized methods and standard materials

Part of the unmet needs and challenges in comparing different BNNT studies are related to the difficulty of comparing results obtained with different BNNT materials or even due to variability between batches of nominally the same material. While a variety of techniques are commonly used for characterizing BNNTs (i.e., electron microscopy, thermogravimetric analysis, FTIR spectroscopy, UV–Vis absorption spectroscopy, Raman spectroscopy, X-ray photoelectron spectroscopy, etc.) there are currently no broadly accepted and employed methods to assess and compare BNNTs between studies. Individual studies can be performed with BNNTs from a single batch, which is advantageous for identifying trends, but this limits comparisons with other studies. Easily accessible spectroscopy-based methods using FTIR spectroscopy [127] and UV–Vis–NIR spectroscopy [128] have recently been described for assessing BNNT purity and quality; however, no method has yet proven to be broadly useful across BNNT materials or been used extensively by many groups. Therefore, the mere reporting of the purity of BNNT materials can be unclear. In addition to field-accepted methods of characterizing and comparing BNNT materials, standard reference materials (e.g., BNNT-1) [129] also have a role to play in enabling inter-lab comparison and the development of improved characterization methods for BNNTs. Notably, lack of clarity in nomenclature and characterization will hold back the growth of the field because resources—e.g., government funding and venture capital—will be scattered over a broad set of efforts with the same name yet fundamentally different properties and potential. This could lead to the same hype-disillusionment cycle that was experienced in the CNT field in the 2010s.

Strength in diversity

Uniformity and consistency are essential in terms of standard materials and for achieving broad consensus on how to characterize, report, and make comparisons between studies; however, diversity is also an advantage in finding application niches for BNNTs. In general, BNNTs are less a competitor to CNTs (or graphene and other related nanomaterials) than part of an expanded set of related nanomaterials with complementary advantages. Even within BNNTs, the current and mostly powder-like commercial materials can be expected to be suitable for some applications, while emerging macroscopic articles (buckypapers, aligned sheets and fibers, and vertical BNNT arrays) will be advantageous or necessary in other cases. Continuing to increase the number of researchers joining the field, as was done over the past decade, will be critical for adding diversity of expertise and ideas, which will push the field to new heights in ways beyond those considered here.

In summary, remarkable progress has occurred since the discovery of BNNTs and increasing availability of BNNTs and research activity makes this an exciting time for the field. BNNTs have already earned a place as a leading nanomaterial and there is no doubt that the 2020s will see a significant growth of the field as well as the emergence of commercial applications based on or enabled by BNNTs.

Data availability

Not applicable.

References

N.G. Chopra, R.J. Luyken, K. Cherrey, V.H. Crespi, M.L. Cohen, S.G. Louie, A. Zettl, Boron nitride nanotubes. Science 267, 966–967 (1995). https://doi.org/10.1126/science.269.5226.966

A. Rubio, J.L. Corkill, M.L. Cohen, Theory of graphitic boron nitride nanotubes. Phys. Rev. B 49, 5081–5084 (1994). https://doi.org/10.1103/PhysRevB.49.5081

S. Ijima, Helical microtubules of graphitic carbon. Nature 354, 56–58 (1991). https://doi.org/10.1038/354056a0

D. Golberg, Y. Bando, M. Eremets, K. Takemura, K. Kurashima, H. Yusa, Nanotubes in boron nitride laser heated at high pressure. Appl. Phys. Lett. 69, 2045 (1996). https://doi.org/10.1063/1.116874

A. Loiseau, F. Willaime, N. Demoncy, G. Hug, H. Pascard, Boron nitride nanotubes with reduced numbers of layers synthesized by arc discharge. Phys. Rev. Lett. 76, 4737 (1996). https://doi.org/10.1103/PhysRevLett.76.4737

Y. Chen, J.F. Gerald, J.S. Williams, S. Bulcock, Synthesis of boron nitride nanotubes at low temperatures using reactive ball milling. Chem. Phys. Lett. 299, 260–264 (1999). https://doi.org/10.1016/S0009-2614(98)01252-4

J. Cummings, A. Zettl, Mass-production of boron nitride double-wall nanotubes and nanococoons. Chem. Phys. Lett. 316, 211–216 (2000). https://doi.org/10.1016/S0009-2614(99)01277-4

Y. Chen, M. Conway, J.S. Williams, J. Zou, Large-quantity production of high-yield boron nitride nanotubes. J. Mater. Res. 17, 1896–1899 (2002). https://doi.org/10.1557/JMR.2002.0281

C. Zhi, Y. Bando, C. Tan, D. Golberg, Effective precursor for high yield synthesis of pure BN nanotubes. Solid State Commun. 135, 67–70 (2005). https://doi.org/10.1016/j.ssc.2005.03.062

K.S. Kim, M.J. Kim, C. Park, C.C. Fay, S.-H. Chu, C.T. Kingston, B. Simard, Scalable manufacturing of boron nitride nanotubes and their assemblies. Semicond. Sci. Technol. 32, 013003 (2017). https://doi.org/10.1088/0268-1242/32/1/013003

M.F.L. De Volder, S.H. Tawfick, R.H. Baughman, A.J. Hart, Carbon nanotubes: present and future commercial applications. Science 339, 535–539 (2013). https://doi.org/10.1126/science.1222453

M. Davenport, Twists and Shouts: a nanotube story, Chem. Eng. News 93(23) (2015). https://cen.acs.org/articles/93/i23/Twists-Shouts-Nanotube-Story.html

M. McCoy, Bayer will exit carbon nanotubes, Chem. Eng. News 91(19) (2013). https://cen.acs.org/articles/91/i19/Bayer-Exit-Carbon-Nanotubes.html

J.H. Kim, T.V. Pham, J.H. Hwang, C.S. Kim, M.J. Kim, Boron nitride nanotubes: synthesis and applications. Nano Converg. 5, 17 (2018). https://doi.org/10.1186/s40580-018-0149-y

M.B. Jakubinek, B. Ashrafi, Y. Martinez-Rubi, J. Guan, M. Rahmat, K.S. Kim, S. Denommee, C.T. Kingston, B. Simard, Boron nitride nanotube composites and applications, in Nanotube Superfiber Materials, 2nd edn., ed. by M.J. Schulz, V. Shanov, Z. Yin, M. Cahay (Elsevier, Amsterdam, 2019), pp.92–111. https://doi.org/10.1016/B978-0-12-812667-7.00005-7

N. Yanar, E. Yang, H. Park, M. Son, H. Choi, Boron nitride nanotube (BNNT) membranes for energy and environmental applications. Membranes 10, 430 (2020). https://doi.org/10.3390/membranes10120430

T. Xu, K. Zhang, Q. Cai, N. Wang, L. Wu, Q. He, H. Wang, Y. Zhang, Y. Xie, Y. Yao, Y. Chen, Advances in synthesis and applications of boron nitride nanotubes: a review. Chem. Eng. J. 431, 134118 (2022). https://doi.org/10.1016/j.cej.2021.134118

E.A. Turhan, A.E. Pazarceviren, Z. Evis, A. Tezcaner, Properties and applications of boron nitride nanotubes. Nanotechnology 33, 242001 (2022). https://doi.org/10.1088/1361-6528/ac5839

Nanotube Modeler: Generation of Nano-geometries, Version 1.8 (10/01/2018). ©JCrystalSoft, 2005–2018. http://jcrystal.com/products/wincnt/

C.H. Lee, S. Bhandari, B. Tiwari, N. Yapici, D. Zhang, Y.K. Yap, Boron nitride nanotubes: recent advances in their synthesis, functionalization, and applications. Molecules 21, 922 (2016). https://doi.org/10.3390/molecules21070922

BNNT manufacturer websites: BNNT LLC (www.bnnt.com); Tekna (www.tekna.com); NAiEEL Technology (www.naieel.com/); BNNano (www.bnnano.com); BNNT Technology LTD (www.bnnt.com.au). Accessed 1 July 2022

M.W. Smith, K.C. Jordan, C. Park, J.-W. Kim, P.T. Lillehei, R. Crooks, J.S. Harrison, Very long single- and few-walled boron nitride nanotubes via the pressurized vapor/condenser method. Nanotechnology 20, 505604 (2009). https://doi.org/10.1088/0957-4484/20/50/505604

A. Fathalizadeh, T. Pham, W. Mickelson, A. Zettl, Scaled synthesis of boron nitride nanotubes, nanoribbons, and nanococoons using direct feedstock injection into an extended-pressure, inductively-coupled thermal plasma. Nano Lett. 14, 4881 (2014). https://doi.org/10.1021/nl5022915

K.S. Kim, C.T. Kingston, A. Hrdina, M.B. Jakubinek, J. Guan, M. Plunkett, B. Simard, Hydrogen-catalyzed, pilot-scale production of small-diameter boron nitride nanotubes and their macroscopic assemblies. ACS Nano 8, 6211–6220 (2014). https://doi.org/10.1021/nn501661p

M. Kim, J.H. Oh, S.H. Hong, Y.H. Lee, T.-H. Kim, S. Choi, Synthesis of boron nitride nanotubes in thermal plasma with continuous injection of boron under atmospheric pressure. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00670-7

J. Guan, K.S. Kim, M.B. Jakubinek, B. Simard, pH-switchable water-soluble boron nitride nanotubes. ChemistrySelect 3, 9308–9312 (2018). https://doi.org/10.1002/slct.201801544

D.M. Marincel, M. Adnan, J. Ma, E.A. Bengio, M.A. Trafford, O. Kleinerman, D.V. Kosynkin, S.-H. Chu, C. Park, S.J.A. Hocker, C.C. Fay, S. Arepalli, A.A. Martí, Y. Talmon, M. Pasquali, Scalable purification of boron nitride nanotubes via wet thermal etching. Chem. Mater. 31, 1520–1527 (2019). https://doi.org/10.1021/acs.chemmater.8b03785

H. Cho, S. Walker, M. Plunkett, D. Ruth, R. Iannitto, Y. Martinez Rubi, K.S. Kim, C.M. Homenick, A. Brinkmann, M. Couillard, S. Dénommée, J. Guan, M.B. Jakubinek, Z.J. Jakubek, C.T. Kingston, B. Simard, Scalable gas-phase purification of boron nitride nanotubes by selective chlorine etching. Chem. Mater. 32, 3911–3921 (2020). https://doi.org/10.1021/acs.chemmater.0c00144

A.O. Maselugbo, H.B. Harrison, J.R. Alston, Boron nitride nanotubes: a review of recent progress on purification methods and techniques. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00672-5

K.S. Kim, G. Sigouin, H. Cho, M. Couillard, M. Gallerneault, S.Y. Moon, H.S. Lee, M.J. Kim, S.G. Jang, H. Shin, Insight into BN impurity formation during boron nitride nanotube synthesis by high-temperature plasma. ACS Omega 6, 27418–27429 (2021). https://doi.org/10.1021/acsomega.1c04361

D.S. Bae, C. Kim, H. Lee, O. Khater, K.S. Kim, H. Shin, K.-H. Lee, M.J. Kim, Spontaneous formation of boron nitride nanotube fibers by boron impurity reduction in laser ablation of ammonia borane. Nano Converg. 9, 1–10 (2022). https://doi.org/10.1186/s40580-022-00312-y

B. McLean, G.B. Webber, A.J. Page, Boron nitride nanotube nucleation via network fusion during catalytic chemical vapor deposition. J. Am. Chem. Soc. 141, 13385–13393 (2019). https://doi.org/10.1021/jacs.9b03484

R.Y. Tay, H. Li, S.H. Tsang, L. Jing, D. Tan, M. Wei, E.H.T. Teo, Facile synthesis of millimeter-scale vertically aligned boron nitride nanotube forests by template-assisted chemical vapor deposition. Chem. Mater. 27, 7156–7163 (2015). https://doi.org/10.1021/acs.chemmater.5b03300

M. Liu, Z. Wang, Y. Zheng, M. Takeuchi, T. Inoue, R. Xiang, S. Maruyama, Synthesis of vertically aligned boron nitride nanotubes with a template of single-walled carbon nanotubes. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00759-z

R.S. Lee, J. Gavillet, M. Lamy de la Chapelle, A. Loiseau, J.-L. Cochon, D. Pigache, J. Thibault, F. Willaime, Catalyst-free synthesis of boron-nitride single-wall nanotubes with a preferred zig-zag configuration. Phys. Rev. B 64, 121405(R) (2001). https://doi.org/10.1103/PhysRevB.64.121405

D.E. Tsentalovich, R.J. Headrick, F. Mirri, J. Hao, N. Behabtu, C.C. Young, M. Pasquali, Influence of carbon nanotube characteristics on macroscopic fiber properties. ACS Appl. Mater. Interfaces 9, 36189–36198 (2017). https://doi.org/10.1021/acsami.7b10968

R. Xiang, S. Maruyama, Heteronanotubes: challenges and opportunities. Small Sci. 1, 2000039 (2021). https://doi.org/10.1002/smsc.202000039

D. Zhang, N. Yapici, R. Oakley, Y.K. Yap, The rise of boron nitride nanotubes for applications in energy harvesting, nanoelectronics, quantum materials, and biomedicine. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00737-5

R. Xiang, T. Inoue, Y. Zheng, A. Kumamoto, Y. Qian, Y. Sato, M. Liu, D. Tang, D. Gokhale, J. Guo, K. Hisama, S. Yotsumoto, T. Ogamoto, K. Arai, Y. Kobayshi, H. Zhang, B. Hou, A. Anisimova, M. Maruyama, Y. Miyata, S. Okada, S. Chiashi, Y. Li, J. Kong, E.I. Kauppinen, Y. Ikuhara, K. Suenaga, S. Maruyama, One-dimensional van der Waals heterostructures. Science 367, 537–542 (2020). https://doi.org/10.1126/science.aaz2570

X. Zhou, F.-C. Hsia, Y. Xue, D.-M. Tang, O. Cretu, C. Zhang, M. Mitome, Y. Bando, T. Sasaki, D. Golberg, Tunable mechanical and electrical properties of coaxial BN-C nanotubes. Phys. Status Solidi RRL 13, 1800576 (2019). https://doi.org/10.1002/pssr.201800576

H. Meng, S. Maruyama, R. Xiang, N. Yang, Thermal conductivity of one-dimensional carbon-boron nitride van der Waals heterostructure: a molecular dynamics study. Int. J. Heat Mass Transf. 180, 121773 (2021). https://doi.org/10.1016/j.ijheatmasstransfer.2021.121773

T. Zhao, J. Shi, M. Huo, R. Wan, Electronic properties of C-doped boron nitride nanotubes studied by first-principles calculations. Physica E 64, 123–128 (2014). https://doi.org/10.1016/j.physe.2014.07.016

Q. Wang, G. Fan, H. Xu, X. Tu, X. Wang, X. Chu, C-doped boron nitride nanotubes for the catalysis of acetylene hydrochlorination: a density functional theory study. Mol. Catal. 488, 110853 (2020). https://doi.org/10.1016/j.mcat.2020.110853

Q. Weng, X. Wang, X. Wang, Y. Bando, D. Golberg, Functionalized hexagonal boron nitride nanomaterials: emerging properties and applications. Chem. Soc. Rev. 45, 3989–4012 (2016). https://doi.org/10.1039/C5CS00869G

M. Foroutan, S. Jamilaldin Fatemi, S. Mahmood Fatemi, A mini-review on dispersion and functionalization of boron nitride nanotubes. J. Nanostruct. Chem. 10, 265–274 (2020). https://doi.org/10.1007/s40097-020-00347-9

A.D. Smith McWilliams, C. Martinez-Jimenez, K.R. Shumard, M. Pasquali, A.A. Marti, Dispersion and individualization of boron nitride nanotubes. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00696-x

C. Zhi, Y. Bando, C. Tang, R. Xie, T. Sekiguchi, D. Golberg, Perfectly dissolved boron nitride nanotubes due to polymer wrapping. J. Am. Chem. Soc. 127(46), 15996 (2005). https://doi.org/10.1021/ja053917c

C. Zhi, Y. Bando, C. Tang, S. Honda, K. Sato, H. Kuwahara, D. Golberg, Covalent functionalization: towards soluble multiwalled boron nitride nanotubes. Angew. Chem. Int. Ed. 44, 7932 (2005). https://doi.org/10.1002/anie.200502846

H. Shin, J. Guan, M.Z. Zgierski, K.S. Kim, C.T. Kingston, B. Simard, Covalent functionalization of boron nitride nanotubes via reduction chemistry. ACS Nano 9, 12573 (2015). https://doi.org/10.1021/acsnano.5b06523

C.A. de los Reyes, K.L. WalzMitra, A.D. Smith, S. Yazdi, A. Loredo, F.J. Frankovsky, E. Ringe, M. Pasquali, A.A. Martí, Chemical decoration of boron nitride nanotubes using the Billups-Birch reaction: toward enhanced thermostable reinforced polymer and ceramic nanocomposites. ACS Appl. Nano Mater. 1, 2421 (2018). https://doi.org/10.1021/acsanm.8b00633

A.O. Maselugbo, J.E. Knoop, K.S. Nowlin, G. Pathiraja, H.B. Harrison, J.R. Alston, Controlled ultrasonication for covalent functionalization of boron nitride nanotubes. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00685-0

M. Adnan, D.M. Marincel, O. Kleinerman, S.-H. Chu, C. Park, S.J.A. Hocker, C. Fay, S. Arepalli, Y. Talmon, M. Pasquali, Extraction of boron nitride nanotubes and fabrication of macroscopic articles using chlorosulfonic acid. Nano Lett. 18, 1615 (2018). https://doi.org/10.1021/acs.nanolett.7b04335

H. Shin, E. Yeverovich, K.S. Kim, Poly(4-vinylpyridine) adsorption on boron nitride nanotubes and hexagonal boron nitride: a comparative molecular dynamics study. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00705-z

A. Nigues, A. Siria, P. Vincent, P. Poncharal, L. Bocquet, Ultrahigh interlayer friction in multiwalled boron nitride nanotubes. Nat. Mater. 13, 688 (2014). https://doi.org/10.1038/nmat3985

X. Chen, L. Zhang, C. Park, C.C. Fay, X. Wang, C. Ke, Mechanical strength of boron nitride nanotube–polymer interfaces. Appl. Phys. Lett. 107, 253105 (2015). https://doi.org/10.1063/1.4936755

A.T. Nasrabadi, M. Foroutan, Interactions between polymers and single-walled boron nitride nanotubes: a molecular dynamics simulation approach. J. Phys. Chem. C 114, 15429 (2010). https://doi.org/10.1021/jp106330c

J. Lee, D.-M. Lee, Y. Jung, J. Park, H.S. Lee, Y.-K. Kim, C.R. Park, H.S. Jeong, S.M. Kim, Direct spinning and densification method for high-performance carbon nanotube fibers. Nat. Commun. 10, 1–10 (2019). https://doi.org/10.1038/s41467-019-10998-0

D.S. Lashmore, T. Bennett, Continuous boron nitride nanotube yarns and methods of production. US20200255985A1 (2020)

C.H. Lee, M. Xie, V. Kayastha, J. Wang, Y.K. Yap, Patterned growth of boron nitride nanotubes by catalytic chemical vapor deposition. Chem. Mater. 22, 1782 (2010). https://doi.org/10.1021/cm903287u

L.H. Li, Y. Chen, A.M. Glushenkov, Boron nitride nanotube films grown from boron ink painting. J. Mater. Chem. 20, 9679–9683 (2010). https://doi.org/10.1039/C0JM01414A

V.R. Kode, M.E. Thompson, C. McDonald, J. Weicherding, T.D. Dobrila, P.S. Fodor, C.L. Wirth, G. Ao, Purification and assembling of DNA-stabilized BNNTs into aligned films. ACS Appl. Nano Mater. 2, 2099–2105 (2019). https://doi.org/10.1021/acsanm.9b00088

C.J. Simonsen Ginestra, C. Martínez-Jiménez, A. Matatyaho Ya’akobi, O.S. Dewey, A.D. Smith McWilliams, R.J. Headrick, J.A. Acapulco, L.R. Scammell, M.W. Smith, D.V. Kosynkin, D.M. Marincel, C. Park, S.-H. Chu, Y. Talmon, A.A. Marti, M. Pasquali, Liquid crystals of neat boron nitride nanotubes and their assembly into ordered macroscopic materials. Nat. Commun. 13, 3136 (2022). https://doi.org/10.1038/s41467-022-30378-5

M. Zhang, K.R. Atkinson, R.H. Baughman, Multifunctional carbon nanotube yarns by downsizing ancient technology. Science 306, 1358–1361 (2004). https://doi.org/10.1126/science.1104276

K.S. Kim, M.B. Jakubinek, Y. Martinez-Rubi, B. Ashrafi, J. Guan, K. O’Neill, M. Plunkett, A. Hrdina, S. Lin, S. Denommee, C. Kingston, B. Simard, Polymer nanocomposites from free-standing, macroscopic boron nitride nanotube assemblies. RSC Adv. 5, 41186–41192 (2015). https://doi.org/10.1039/C5RA02988K

P. Nautiyal, C. Zhang, A. Loganathan, B. Boesl, A. Agarwal, High-temperature mechanics of boron nitride nanotube “buckypaper” for engineering advanced structural materials. ACS Appl. Nano Mater. 2, 4402–4416 (2019). https://doi.org/10.1021/acsanm.9b00817

A. Matatyaho Ya’akobi, C.J.S. Ginestra, L.R. Scammell, M.W. Smith, M. Pasquali, Y. Talmon, Electron microscopy study of BNNTs synthesized by high temperature–pressure method and purified by high-temperature steam. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00697-w

R. Rezaei, S.M.V. Allaei, Effects of preexisting cracks on tensile behavior and deformation mechanism of boron nitride nanoribbons: a molecular dynamics investigation. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00607-0

K.S. Kim, M.B. Jakubinek, Y. Martinez-Rubi, B. Ashrafi, J. Guan, K. O’Neill, M. Plunkett, A. Hrdina, S. Lin, S. Dénommée, C. Kingston, B. Simard, Polymer nanocomposites from free-standing, macroscopic boron nitride nanotube assemblies. RSC Adv. 5, 41186–41192 (2015)

S. Ye, C. Cheng, X. Chen, J. Shao, J. Zhang, H. Hu, H. Tian, X. Li, L. Ma, W. Jia, High-performance piezoelectric nanogenerator based on microstructured P(VDF-TrFE)/BNNTs composite for energy harvesting and radiation protection in space. Nano Energy 60, 701–714 (2019). https://doi.org/10.1016/j.nanoen.2019.03.096

J.H. Kang, G. Sauti, C. Park, V.I. Yamakov, K.E. Wise, S.E. Lowther, C.C. Fay, S.A. Thibeault, R.G. Bryant, Multifunctional electroactive nanocomposites based on piezoelectric boron nitride nanotubes. ACS Nano 9, 11942–11950 (2015). https://doi.org/10.1021/acsnano.5b04526

P. Snapp, C. Cho, D. Lee, M.F. Haque, S.W. Nam, C. Park, Tunable piezoelectricity of multifunctional boron nitride nanotube/poly(dimethylsiloxane) stretchable composites. Adv. Mater. 32, 2004607 (2020). https://doi.org/10.1002/adma.202004607

S.H. Kang, G.M. Choi, J. Rahmannezhad, C. Kim, Y.-K. Kim, S. Ahn, S.G. Jang, M.J. Kim, H.S. Lee, Purity and concentration dependence of piezoelectricity and thermal conductivity of boron nitride nanotubes. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00757-1

C. Zhi, Y. Bando, C. Tang, S. Honda, H. Kuwahara, D. Golberg, Boron nitride nanotubes/polystyrene composites. J. Mater. Res. 21, 2794 (2006). https://doi.org/10.1557/JMR.2006.0340

M.B. Jakubinek, B. Ashrafi, Y. Martinez-Rubi, M. Rahmat, M. Yourdkhani, K.S. Kim, K. Laqua, A. Yousefpour, B. Simard, Nanoreinforced epoxy and adhesive joints incorporating boron nitride nanotubes. Int. J. Adhes. Adhes. 84, 194–201 (2018). https://doi.org/10.1016/j.ijadhadh.2018.03.008

F.R. Bohns, F.W. Degrazia, G. de Souza Balbinot, V.C. Branco Leitune, S.M. Werner Samueal, M.A. Garcia-Esparza, S. Sauro, F.M. Collares, Boron nitride nanotubes as filler for resin-based dental sealants. Sci. Rep. 9, 7710 (2019). https://doi.org/10.1038/s41598-019-44246-8

C. Zhi, Y. Bando, T. Terao, C. Tang, H. Kuwahara, D. Golberg, Towards thermoconductive, electrically insulating polymeric composites with boron nitride nanotubes as fillers. Adv. Funct. Mater. 19, 1857 (2009). https://doi.org/10.1002/adfm.200801435

M.B. Jakubinek, J.F. Niven, M.B. Johnson, B. Ashrafi, K.S. Kim, B. Simard, M.A. White, Thermal conductivity of bulk boron nitride nanotube sheets and their epoxy-impregnated composites. Phys. Status Solidi A 213, 2237 (2016). https://doi.org/10.1002/pssa.201533010

C. Zhang, R. Huang, Y. Wang, Z. Wu, H. Zhang, Y. Li, W. Wang, C. Huang, L. Li, Self-assembled boron nitride nanotube reinforced graphene oxide aerogels for dielectric nanocomposites with high thermal management capability. ACS Appl. Mater. Interfaces 12, 1436–1443 (2020). https://doi.org/10.1021/acsami.9b15993

Y. Martinez-Rubi, B. Ashrafi, M.B. Jakubinek, S. Zou, K.S. Kim, H. Cho, B. Simard, Nanocomposite fabrics with high content of boron nitride nanotubes for tough and multifunctional composites. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00707-x

N. Anjum, O.Q. Alsmairat, Z. Liu, C. Park, C.C. Fay, C. Ke, Mechanical characterization of electrospun boron nitride nanotube-reinforced polymer nanocomposite microfibers. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00653-8

J.F. Khoury, J.C. Viltale, T.L. Larson, G. Ao, Boron nitride nanotubes enhance mechanical properties of fibers from nanotube/polyvinyl alcohol dispersions. Nanoscale Adv. 4, 77–86 (2022). https://doi.org/10.1039/D1NA00677K

H. Chang, M. Lu, P.J. Arias-Monje, J. Luo, C. Park, S. Kumar, Determining the orientation and interfacial stress transfer of boron nitride nanotube composite fibers for reinforced polymeric materials. ACS Appl. Nano Mater. 2, 6670 (2019). https://doi.org/10.1021/acsanm.9b01573

H. Chang, M. Lu, J. Luo, J.G. Park, R. Liang, C. Park, S. Kumar, Polyacrylonitrile/boron nitride nanotubes composite precursor and carbon fiber. Carbon 147, 419–426 (2019). https://doi.org/10.1016/j.carbon.2019.03.026

J.E. Estevez, B.G. Harvey, G.S. Ostrom, G.H. Hefley, C.G. Yelton, M.D. Garrison, Beyond percolation threshold loading of polyacrylonitrile electrospun nanofibers with boron nitride nanotubes for use in high-temperature composites. ACS Appl. Nano Mater. 2, 7585–7592 (2019). https://doi.org/10.1021/acsanm.9b01684

G. Sachdeva, S.U. Patil, S.S. Bamane, P.P. Deshpande, W.A. Pisani, G.M. Odegard, R. Pandey, Mechanical response of polymer/BN composites investigated by molecular dynamics method. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00725-9

M. Ghazizadeh, J. Estevez, A. Kelkar, Boron nitride nanotubes for space radiation shielding. Int. J. Nano Stud. Technol. (2015). https://doi.org/10.19070/2167-8685-150007e

S.A. Thibeault, J.H. Kang, G. Sauti et al., Nanomaterials for radiation shielding. MRS Bull. 40, 836–841 (2015). https://doi.org/10.1557/mrs.2015.225

Z. Yamani, H. Ha, M. Jakubinek, Y. Martinez-Rubi, B. Simard, B. Ashrafi, Effects of gamma irradiation on boron nitride nanotubes and related polymer nanocomposites, J. Mater. Res. (2022)

N. Bacca, C. Zhang, T. Paul, A. Kunneparambil Sukumaran, D. John, S. Rengifo, C. Park, S.-H. Chu, M. Mazurkivich, W. Scott, A. Agarwal, Tribological and neutron radiation properties of boron nitride nanotubes reinforced titanium composites under lunar environment. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00708-w

M.J. Tank, A.N. Reyes, J.G. Park, L.R. Scammell, M.W. Smith, A. De Leon, R.D. Sweat, Extreme thermal stability and dissociation mechanisms of purified boron nitride nanotubes: implications for high-temperature nanocomposites. ACS Appl. Nano Mater. 5, 12444–12453 (2022). https://doi.org/10.1021/acsanm.2c01965

X. Lu, T. Dolmetsch, C. Zhang, Y. Chen, B. Boesl, A. Agarwal, In-situ synthesis of Boron Nitride Nanotube reinforced aluminum oxide composites by molecular mixing. Ceram. Int. 47, 13970–13979 (2021). https://doi.org/10.1016/j.ceramint.2021.01.266

N. Yang, S. Xu, C. Xu, Highly electromagnetic transparent ceramic composite made of boron nitride nanotubes and silicon oxynitride via perhydropolysilazane infiltration method. Sci. Rep. 12, 14374 (2022). https://doi.org/10.1038/s41598-022-18563-4

M. Yamaguchi, F. Meng, K. Firestein, K. Tsuchiya, D. Golberg, Powder metallurgy routes toward aluminum boron nitride nanotube composites, their morphologies, structures and mechanical properties. Mater. Sci. Eng. A 604, 9–17 (2014). https://doi.org/10.1016/j.msea.2014.02.086

C. Rohmann, V.I. Yamakov, C. Park, C. Fay, M. Hankel, D.J. Searles, Interaction of boron nitride nanotubes with aluminum: a computational study. J. Phys. Chem. C 122, 15226–15240 (2018). https://doi.org/10.1021/acs.jpcc.8b00774

J. Bustillos, X. Lu, P. Nautiyal, C. Zhang, B. Boesl, A. Agarwal, Boron nitride nanotube-reinforced titanium composite with controlled interfacial reactions by spark plasma sintering. Adv. Eng. Mater. 22, 2000702 (2022). https://doi.org/10.1002/adem.202000702

Q. Chao, S. Mateti, M. Annasamy, M. Imran, J. Joseph, Q. Cai, L.H. Li, P. Cizek, P.D. Hodgson, Y. Chen, D. Fabijanic, W. Xu, Nanoparticle-mediated ultra grain refinement and reinforcement in additively manufactured titanium alloys. Addit. Manuf. 46, 102173 (2021). https://doi.org/10.1016/j.addma.2021.102173

G. Ciofani, V. Raffa, A. Menciassi, P. Dario, Preparation of boron nitride nanotubes aqueous dispersions for biological applications. J. Nanosci. Nanotechnol. 8, 6223 (2008). https://doi.org/10.1166/jnn.2008.18375

V. Kodali, J.R. Roberts, E. Glassford, R. Gill, S. Friend, K.L. Dunn, A. Erdely, Understanding toxicity associated with boron nitride nanotubes: review of toxicity studies, exposure assessment at manufacturing facilities, and read-across. J. Mater. Res. (2022). https://doi.org/10.1557/s43578-022-00796-8

X. Li, C. Zhi, N. Hanagata, M. Yamaguchi, Y. Bando, D. Golberg, Boron nitride nanotubes functionalized with mesoporous silica for intracellular delivery of chemotherapy drugs. Chem. Commun. (Camb.) 49(66), 7337 (2013). https://doi.org/10.1039/c3cc42743a

J.S. Maria Nithya, A. Pandurangan, Aqueous dispersion of polymer coated boron nitride nanotubes and their antibacterial and cytotoxicity studies. RSC Adv. 4(60), 32031 (2014). https://doi.org/10.1039/c4ra04846f

H. Nakamura, H. Koganei, T. Miyoshi, Y. Sakurai, K. Ono, M. Suzuki, Antitumor effect of boron nitride nanotubes in combination with thermal neutron irradiation on BNCT. Bioorg. Med. Chem. Lett. 25(2), 172 (2015). https://doi.org/10.1016/j.bmcl.2014.12.005

X. Chen, P. Wu, M. Rousseas, D. Okawa, Z. Gartner, A. Zettl, C.R. Bertozzi, Boron nitride nanotubes are noncytotoxic and can be functionalized for interaction with proteins and cells. J. Am. Chem. Soc. 131(3), 890 (2009). https://doi.org/10.1021/ja807334b

T.H. Ferreira, L.M. Hollanda, M. Lancellotti, E.M. de Sousa, Boron nitride nanotubes chemically functionalized with glycol chitosan for gene transfection in eukaryotic cell lines. J. Biomed. Mater. Res. A 103(6), 2176 (2015). https://doi.org/10.1002/jbm.a.35333

X. Li, N. Hanagata, X. Wang, M. Yamaguchi, W. Yi, Y. Bando, D. Golberg, Multimodal luminescent-magnetic boron nitride nanotubes@NaGdF(4): Eu structures for cancer therapy. Chem. Commun. (Camb.) 50(33), 4371 (2014). https://doi.org/10.1039/c4cc00990h

D. Lahiri, V. Singh, A.P. Benaduce, S. Seal, L. Kos, A. Agarwal, Boron nitride nanotube reinforced hydroxyapatite composite: mechanical and tribological performance and in vitro biocompatibility to osteoblasts. J. Mech. Behav. Biomed. Mater. 4(1), 44 (2011). https://doi.org/10.1016/j.jmbbm.2010.09.005

X. Li, X. Wang, X. Jiang, M. Yamaguchi, A. Ito, Y. Bando, D. Golberg, Boron nitride nanotube-enhanced osteogenic differentiation of mesenchymal stem cells. J. Biomed. Mater. Res. B 104(2), 323 (2016). https://doi.org/10.1002/jbm.b.33391

A. Salvetti, L. Rossi, P. Iacopetti, X. Li, S. Nitti, T. Pellegrino, V. Mattoli, D. Golberg, G. Ciofani, In vivo biocompatibility of boron nitride nanotubes: effects on stem cell biology and tissue regeneration in planarians. Nanomedicine (Lond.) 10(12), 1911 (2015). https://doi.org/10.2217/nnm.15.46

D.C. Soares, T.H. Ferreira, A.C. de Ferreira, V.N. Cardoso, E.M. de Sousa, Boron nitride nanotubes radiolabeled with 99mTc: preparation, physicochemical characterization, biodistribution study, and scintigraphic imaging in Swiss mice. Int. J. Pharm. 423(2), 489 (2012). https://doi.org/10.1016/j.ijpharm.2011.12.002

R. Ma, Y. Bando, H. Zhu, T. Sato, C. Xu, D. Wu, Hydrogen uptake in boron nitride nanotubes at room temperature. J. Am. Chem. Soc. 124, 7674–7673 (2002). https://doi.org/10.1021/ja026030e

C.H. Lee, S. Qin, M.A. Savaikar, J. Wang, B. Hao, D. Zhang, D. Banyai, J.A. Jaszcak, K.W. Clark, J.-C. Idrobo, A.-P. Li, Y.K. Yap, Room-temperature tunnelling behaviour of boron nitride nanotubes functionalized by gold quantum dots. Adv. Mater. 25, 4544 (2013). https://doi.org/10.1002/adma.201301339

J.-K. Qin, P.-Y. Liao, M. Si, S. Gao, G. Qiu, J. Jian, Q. Wang, S.-Q. Zhang, S. Huang, A. Charnas, Y. Wang, M.J. Kim, W. Wu, X. Xu, H.-Y. Wang, L. Yang, Y.K. Yap, P.D. Ye, Raman response and transport properties of tellurium atomic chains encapsulated in nanotubes. Nat. Electron. 3, 141–147 (2020). https://doi.org/10.1038/s41928-020-0365-4

X. Hong, D. Wang, D.D.L. Chung, Boron nitride nanotube mat as a low-k dielectric material with relative dielectric constant ranging from 1.0 to 1.1. J. Electron. Mater. 45, 453–461 (2016). https://doi.org/10.1007/s11664-015-4123-8

K. Wagner, C. Paquet, Y. Martinez-Rubi, M. Genest, J. Guan, K.L. Sampson, K.S. Kim, A.J. Kell, P.R.L. Malenfant, B.H. Lessard, Boron nitride nanotube coatings for thermal management of printed silver inks on temperature sensitive substrates. Adv. Electron. Mater. 7, 2001035 (2021). https://doi.org/10.1002/aelm.202001035

C. Allard, L. Schué, F. Fossard, G. Recher, R. Nascimento, E. Flahaut, A. Loiseau, P. Desjardins, R. Martel, E. Gaufrès, Adv. Mater. 32, 2001429 (2020). https://doi.org/10.1002/adma.202001429

H. Lim, B.L. Suh, M.J. Kim, H. Yun, J. Kim, B.J. Kim, S.G. Jang, High-performance, recyclable ultrafiltration membranes from P4VP-assisted dispersion of flame-resistive boron nitride nanotubes. J. Membr. Sci. 551, 172–179 (2018). https://doi.org/10.1016/j.memsci.2018.01.030

M.M. Rahman, S. Mateti, Q. Cai, I. Sultana, Y. Fan, X. Wang, C. Hou, Y. Chen, High temperature and high rate lithium-ion batteries with boron nitride nanotubes coated polypropylene separators. Energy Storage Mater. 19, 352–359 (2019). https://doi.org/10.1016/j.ensm.2019.03.027

H.-S. Kim, H.-J. Kang, H. Lim, H.J. Hwang, J.-W. Park, T.-G. Lee, S.Y. Cho, S.G. Jang, Y.-S. Jun, Boron nitride nanotube-based separator for high-performance lithium–sulfur batteries. Nanomaterials 12, 11 (2022). https://doi.org/10.3390/nano12010011

A. Thess, R. Lee, P. Nikolaev, H. Dai, P. Petit, J. Robert, C. Xu, Y.H. Lee, S.G. Kim, A.G. Rinzler, D.T. Colbert, G.E. Scuseria, D. Tomanek, J.E. Fischer, R.E. Smalley, Crystalline ropes of metallic carbon nanotubes. Science 273, 483–487 (1996). https://doi.org/10.1126/science.273.5274.483

A.G. Rinzler, J. Liu, H. Dai, P. Nikolaev, C.B. Huffman, F.J. Rodríguez-Macías, P.J. Boul, A.H. Lu, D. Heymann, D.T. Colbert, R.S. Lee, J.E. Fischer, A.M. Rao, P.C. Eklund, R.E. Smalley, Large-scale purification of single-wall carbon nanotubes: process, product, and characterization. Appl. Phys. A 67, 29–37 (1998)

Tubes@Rice. Internet Archive: https://web.archive.org/web/19990507235125/http://cnst.rice.edu/tubes/

C. Fay. Boron Nitride Nanotube: tiny tube with great potential. TEDxArendal, December 2, 2016.

E.J. Siochi, J.S. Harrison, Structural nanocomposites for aerospace applications. MRS Bull. 40, 829–835 (2015). https://doi.org/10.1557/mrs.2015.228

Mason, NASA Institute develops carbon nanotube-based composites for Mars spacecraft, Composites World (published January 21, 2022). www.compositesworld.com/articles/nasa-institute-developing-carbon-nanotube-based-composites-for-mars-spacecraft

L.M. Ericson, H. Fan, H. Peng, V.A. Davis, W. Zhou, J. Sulpizio, Y. Wang, R. Booker, J.J. Vavro, C. Guthy, A.N.G. Parra-Vasquez, M.J. Kim, S. Ramesh, R.K. Saini, C. Kittrell, G. Lavin, H. Schmidt, W.W. Adams, W.E. Billups, M. Pasquali, W.-F. Hwang, R.H. Hauge, J.E. Fischer, R.E. Smalley, Macroscopic, neat, single-walled carbon nanotube fibers. Science 305, 1447–1450 (2004). https://doi.org/10.1126/science.1101398

N. Behabtu, C.C. Young, D.E. Tsentalovich, O. Kleinerman, X. Wang, A.W.K. Ma, E.A. Bengio, R.F. Ter Waarbeek, J.J. De Jong, R.E. Hoogerwerf, S.B. Fairchild, J.B. Ferguson, B. Maruyama, J. Kono, Y. Talmon, Y. Cohen, M.J. Otto, M. Pasquali, Strong, light, multifunctional fibers of carbon nanotubes with ultrahigh conductivity. Science 339, 182–186 (2013). https://doi.org/10.1126/science.12280

C.P. Huynh, S.C. Hawkins, Understanding the synthesis of directly spinnable carbon nanotube forests. Carbon 48, 1105–1115 (2010). https://doi.org/10.1016/j.carbon.2009.11.032

J.T. Harrison, K.S. Lamb, A.J. Nowlin, K.B. Guenthner, A.D. Ghiassi, J.R. Kelkar, Alston, Quantification of hexagonal boron nitride impurities in boron nitride nanotubes via FTIR spectroscopy. Nanoscale Adv. 1, 1693–1701 (2019). https://doi.org/10.1039/C8NA00251G

Y. Martinez Rubi, Z.J. Jakubek, M. Chen, S. Zou, B. Simard, Quality assessment of bulk boron nitride nanotubes for advancing research, commercial, and industrial applications. ACS Appl. Nano Mater. 2, 2054–2063 (2019). https://doi.org/10.1021/acsanm.9b00057

National Research Council Canada, BNNT-1: Boron Nitride Nanotube Reference Material (National Research Council Canada, 2020). https://doi.org/10.4224/crm.2020.bnnt-1

Acknowledgments

The authors acknowledge the students, colleagues, and collaborators that have contributed to their work in the area of boron nitride nanotubes, as well as the support of their institutions: the National Research Council Canada (Canada), Gachon University, and the Korea Institute of Science and Technology (Republic of Korea), and Rice University (USA). KSK acknowledges a financial support from the Technology Innovation Program (20000479) funded by the Ministry of Trade, Industry and Energy (MOTIE, Korea) and AFOSR (FA9550-18-1-0014). AAM and MP acknowledge the financial support from the National Science Foundation (CHE-1807737 and CHE-2108838), AFOSR (FA9550-19-1-7045), and the Welch Foundation Grant C-1668. MJK acknowledges the financial support from the National Research Foundation of Korea (2021M3F6A1085886) by Korean Government (MSIT) and Korea Research Institute for Defense Technology Planning and Advancement (KRIT) Grant funded by the Korea Government (DAPA (Defense Acquisition Program Administration)) (No. CRIT-CT-21-014, 2021).

Disclaimer

Mentions of product or company names within the manuscript do not constitute an endorsement.

Funding

Open access funding provided by National Research Council Canada.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jakubinek, M.B., Kim, K.S., Kim, M.J. et al. Recent advances and perspective on boron nitride nanotubes: From synthesis to applications. Journal of Materials Research 37, 4403–4418 (2022). https://doi.org/10.1557/s43578-022-00841-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00841-6