Abstract

Open literature publications, in the period from 2010 to the end of January 2018, on refractory high entropy alloys (RHEAs) and refractory complex concentrated alloys (RCCAs) are reviewed. While RHEAs, by original definition, are alloys consisting of five or more principal elements with the concentration of each of these elements between 5 and 35 at.%, RCCAs can contain three or more principal elements and the element concentration can be greater than 35%. The 151 reported RHEAs/RCCAs are analyzed based on their composition, processing methods, microstructures, and phases. Mechanical properties, strengthening and deformation mechanisms, oxidation, and corrosion behavior, as well as tribology, of RHEA/RCCAs are summarized. Unique properties of some of these alloys make them promising candidates for high temperature applications beyond Ni-based superalloys and/or conventional refractory alloys. Methods of development and exploration, future directions of research and development, and potential applications of RHEAs are discussed.

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Microstructural development in equiatomic multicomponent alloys. Mat. Sci. Eng., A 375–377, 213 (2004).

J-W. Yeh, S-K. Chen, J-W. Gan, S-J. Lin, T-S. Chin, T-T. Shun, C-H. Tsau, and S-Y. Chang: Formation of simple crystal structures in Cu–Co–Ni–Cr–Al–Fe–Ti–V alloys with multiprincipal metallic elements. Metall. Mater. Trans. A 35, 2533 (2004).

D.B. Miracle and O.N. Senkov: A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448 (2017).

S. Gorsse, D.B. Miracle, and O.N. Senkov: Mapping the world of complex concentrated alloys. Acta Mater. 135, 177 (2017).

J-W. Yeh, S-K. Chen, S-J. Lin, J-Y. Gan, T-S. Chin, T-T. Shun, C-H. Tsau, and S-Y. Chang: Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299 (2004).

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw: Refractory high-entropy alloys. Intermetallics 18, 1758 (2010).

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle: Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 19, 698 (2011).

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miracle, and C.F. Woodward: Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy. J. Alloy. Comp. 509, 6043 (2011).

O.N. Senkov, J.M. Scott, S.V. Senkova, F. Meisenkothen, D.B. Miracle, and C.F. Woodward: Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. J. Mater. Sci. 47, 4062 (2012).

C-C. Juan, M-H. Tsai, C-W. Tsai, C-M. Lin, W-R. Wang, C-C. Yang, S-K. Chen, S-J. Lin, and J-W. Yeh: Enhanced mechanical properties of HfMoTaTiZr and HfMoNbTaTiZr refractory high-entropy alloys. Intermetallics 62, 76 (2015).

O.N. Senkov and S.L. Semiatin: Microstructure and properties of a refractory high-entropy alloy after cold working. J. Alloy. Comp. 649, 1110 (2015).

C-M. Lin, C-C. Juan, C-H. Chang, C-W. Tsai, and J-W. Yeh: Effect of Al addition on mechanical properties and microstructure of refractory AlxHfNbTaTiZr alloys. J. Alloy. Comp. 624, 100 (2015).

H. Song, F. Tian, and D. Wang: Thermodynamic properties of refractory high entropy alloys. J. Alloys Compd. 682, 773 (2016).

C-C. Juan, M-H. Tsai, C-W. Tsai, W-L. Hsu, C-M. Lin, S-K. Chen, S-J. Lin, and J-W. Yeh: Simultaneously increasing the strength and ductility of a refractory high-entropy alloy via grain refining. Mater. Lett. 184, 200 (2016).

N.D. Stepanov, N.Y. Yurchenko, S.V. Zherebtsov, M.A. Tikhonovsky, and G.A. Salishchev: Aging behavior of the HfNbTaTiZr high entropy alloy. Mater. Lett. 211, 87 (2018).

J. Jayaraj, C. Thinaharan, S. Ningshen, C. Mallika, and U. Kamachi Mudali: Corrosion behavior and surface film characterization of TaNbHfZrTi high entropy alloy in aggressive nitric acid medium. Intermetallics 89, 123 (2017).

S. Zheng, W. Feng, and S. Wang: Elastic properties of high entropy alloys by MaxEnt approach. Comput. Mater. Sci. 142, 332 (2018).

J.P. Couzinie, L. Lilensten, Y. Champion, G. Dirras, L. Perriere, and I. Guillot: On the room temperature deformation mechanisms of a TiZrHfNbTa refractory high-entropy alloy. Mater. Sci. Eng., A 645, 255 (2015).

J.P. Couzinie, G. Dirras, L. Perriere, T. Chauveau, E. Leroy, Y. Champion, and I. Guillot: Microstructure of a near-equimolar refractory high-entropy alloy. Mater. Lett. 126, 285 (2014).

G. Dirras, J. Gubicza, A. Heczel, L. Lilensten, J.P. Couzinie, L. Perriere, I. Guillot, and A. Hocini: Microstructural investigation of plastically deformed Ti20Zr20Hf20Nb20Ta20 high entropy alloy by X-ray diffraction and transmission electron microscopy. Mater. Charact. 108, 1 (2015).

C-C. Juan, K-K. Tseng, W-L. Hsu, M-H. Tsai, C-W. Tsai, C-M. Lin, S-K. Chen, S-J. Lin, and J-W. Yeh: Solution strengthening of ductile refractory HfMoxNbTaTiZr high-entropy alloys. Mater. Lett. 175, 284 (2016).

G. Dirras, H. Couque, L. Lilensten, A. Heczel, D. Tingaud, J.P. Couzinie, L. Perriere, J. Gubicza, and I. Guillot: Mechanical behavior and microstructure of Ti20Hf20Zr20Ta20Nb20 high-entropy alloy loaded under quasi-static and dynamic compression conditions. Mater. Charact. 111, 106 (2016).

G. Dirras, L. Lilensten, P. Djemia, M. Laurent-Brocq, D. Tingaud, J.P. Couzinie, L. Perriere, T. Chauveau, and I. Guillot: Elastic and plastic properties of as-cast equimolar TiHfZrTaNb high-entropy alloy. Mater. Sci. Eng., A 654, 30 (2016).

B. Schuh, B. Volker, J. Todt, N. Schell, L. Perriere, J. Li, J.P. Couzinie, and A. Hohenwarter: Thermodynamic instability of a nanocrystalline, single-phase TiZrNbHfTa alloy and its impact on the mechanical properties. Acta Mater. 142, 201 (2018).

L. Lilensten, J-P. Couzinie, L. Perriere, A. Hocini, C. Keller, G. Dirras, and I. Guillot: Study of a bcc multi-principal element alloy: Tensile and simple shear properties and underlying deformation mechanisms. Acta Mater. 142, 131 (2018).

H. Dobbelstein, M. Thiele, E.L. Gurevich, E.P. George, and A. Ostendorf: Direct metal deposition of refractory high entropy alloy MoNbTaW. Physics Procedia. 83, 624 (2016).

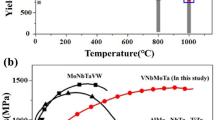

Z.D. Han, N. Chen, S.F. Zhao, L.W. Fan, G.N. Yang, Y. Shao, and K.F. Yao: Effect of Ti additions on mechanical properties of NbMoTaW and VNbMoTaW refractory high entropy alloys. Intermetallics 84, 153 (2017).

X.B. Feng, J.Y. Zhang, Y.Q. Wang, Z.Q. Hou, K. Wu, G. Liu, and J. Sun: Size effects on the mechanical properties of nanocrystalline NbMoTaW refractory high entropy alloy thin films. Int. J. Plast. 95, 264 (2017).

X. Feng, J. Zhang, Z. Xia, W. Fu, K. Wu, G. Liu, and J. Sun: Stable nanocrystalline NbMoTaW high entropy alloy thin films with excellent mechanical and electrical properties. Mater. Lett. 210, 84 (2018).

Z.D. Han, H.W. Luan, X. Liu, N. Chen, X.Y. Li, Y. Shao, and K.F. Yao: Microstructures and mechanical properties of TixNbMoTaW refractory high-entropy alloys. Mater. Sci. Eng., A 712, 380 (2018).

Y. Zou, S. Maiti, W. Steurer, and R. Spolenak: Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy. Acta Mater. 65, 85 (2014).

Y. Zou, P. Okle, H. Yu, T. Sumigawa, T. Kitamura, S. Maiti, W. Steurer, and R. Spolenak: Fracture properties of a refractory high-entropy alloy: In situ micro-cantilever and atom probe tomography studies. Scr. Mater. 128, 95 (2017).

M. Widom, W.P. Huhn, S. Maiti, and W. Steurer: Hybrid Monte Carlo/molecular dynamics simulation of a refractory metal high entropy alloy. Metall. Mater. Trans. A 45, 196 (2014).

W.Y. Wang, J. Wang, D. Lin, C. Zou, Y. Wu, Y. Hu, S-L. Shang, K.A. Darling, Y. Wang, X. Hui, J. Li, L.J. Kecskes, P.K. Liaw, and Z-K. Liu: Revealing the microstates of body-centered-cubic (BCC) equiatomic high entropy alloys. J. Phase Equilib. Diffus. 38, 404 (2017).

M.F. Del Grosso, G. Bozzolo, and H.O. Mosca: Modeling of high entropy alloys of refractory elements. Phys. B 407, 3285 (2012).

B. Zhang, M.C. Gao, Y. Zhang, and S.M. Guo: Senary refractory high-entropy alloy CrxMoNbTaVW. CALPHAD: Comput. Coupling Phase Diagrams Thermochem. 51, 193 (2015).

A. Fernandez-Caballero, J.S. Wrobel, P.M. Mummery, and D. Nguyen-Manh: Short-range order in high entropy alloys: Theoretical formulation and application to Mo–Nb–Ta–V–W system. J. Phase Equilib. Diffus. 38, 391 (2017).

A. Poulia, E. Georgatis, A. Lekatou, and A. Karantzalis: Dry-sliding wear response of MoTaWNbV high entropy alloy. Adv. Eng. Mater. 19, 1600535 (2017).

B. Kang, J. Lee, H.J. Ryu, and S.H. Hong: Ultra-high strength WNbMoTaV high-entropy alloys with fine grain structure fabricated by powder metallurgical process. Mater. Sci. Eng., A 712, 616 (2018).

O.N. Senkov, S.V. Senkova, C. Woodward, and D.B. Miracle: Low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system: Microstructure and phase analysis. Acta Mater. 61, 1545 (2013).

O.N. Senkov, S.V. Senkova, D.B. Miracle, and C. Woodward: Mechanical properties of low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system. Mat. Sci. Eng., A 565, 51 (2013).

F. Tian, L.K. Varga, N. Chen, J. Shen, and L. Vitos: Ab initio design of elastically isotropic TiZrNbMoVx high-entropy alloys. J. Alloys Compd. 599, 19 (2014).

T.M. Butler, K.J. Chaput, J.R. Dietrich, and O.N. Senkov: High temperature oxidation behaviors of equimolar NbTiZrV and NbTiZrCr refractory complex concentrated alloys (RCCAs). J. Alloys Compd. 729, 1004 (2017).

L-Y. Tian, G. Wang, J.S. Harris, D.L. Irving, J. Zhao, and L. Vitos: Alloying effect on the elastic properties of refractory high-entropy alloys. Mater. Des. 114, 243 (2017).

Y.D. Wu, Y.H. Cai, X.H. Chen, T. Wang, J.J. Si, L. Wang, Y.D. Wang, and X.D. Hui: Phase composition and solid solution strengthening effect in TiZrNbMoV high-entropy alloys. Mater. Des. 83, 651 (2015).

O.N. Senkov, S.V. Senkova, and C. Woodward: Effect of aluminum on the microstructure and properties of two refractory high-entropy alloys. Acta Mater. 68, 214 (2014).

O.N. Senkov, C. Woodward, and D.B. Miracle: Microstructure and properties of aluminum-containing refractory high-entropy alloys. JOM 66, 2030 (2014).

O.N. Senkov, D. Isheim, D.N. Seidman, and A.L. Pilchak: Development of a refractory high entropy superalloy. Entropy 18, 102 (2016).

J.K. Jensen, B.A. Welk, R.E.A. Williams, J.M. Sosa, D.E. Huber, O.N. Senkov, G.B. Viswanathan, and H.L. Fraser: Characterization of the microstructure of the compositionally complex alloy Al1Mo0.5Nb1Ta0.5Ti1Zr1. Scr. Mater. 121, 1 (2016).

J.K. Jensen: Characterization of a high strength, refractory high entropy alloy, AlMo0.5NbTa0.5TiZr. Ph.D. dissertation, The Ohio State University, Columbus, OH, 2017; pp. 1–202.

O.N. Senkov, J.K. Jensen, A.L. Pilchak, D.B. Miracle, and H.L. Fraser: Compositional variation effects on the microstructure and properties of a refractory high-entropy superalloy AlMo0.5NbTa0.5TiZr. Mater. Des. 139, 498 (2018).

M.C. Gao, B. Zhang, S. Yang, and S.M. Guo: Senary refractory high-entropy alloy HfNbTaTiVZr. Metall. Mater. Trans. A 47, 3333 (2016).

S. Maiti and W. Steurer: Structural-disorder and its effect on mechanical properties in single-phase TaNbHfZr high-entropy alloy. Acta Mater. 106, 87 (2016).

L. Lilensten, J.P. Couzinie, L. Perriere, J. Bourgon, N. Emery, and I. Guillot: New structure in refractory high-entropy alloys. Mater. Lett. 132, 123 (2014).

E. Fazakas, V. Zadorozhnyy, L.K. Varga, A. Inoue, D.V. Louzguine-Luzgin, F. Tian, and L. Vitos: Experimental and theoretical study of Ti20Zr20Hf20Nb20X20 (X = V or Cr) refractory high-entropy alloys. Int. J. Refract. Metals Hard Mater. 47, 131 (2014).

N.N. Guo, L. Wang, L.S. Luo, X.Z. Li, R.R. Chen, Y.Q. Su, J.J. Guo, and H.Z. Fu: Hot deformation characteristics and dynamic recrystallization of the MoNbHfZrTi refractory high-entropy alloy. Mater. Sci. Eng., A 651, 698 (2016).

O.A. Waseem, J. Lee, H.M. Lee, and H.J. Ryu: The effect of Ti on the sintering and mechanical properties of refractory high-entropy alloy TixWTaVCr fabricated via spark plasma sintering for fusion plasma-facing materials. Mater. Chem. Phys. 210, 87 (2018).

B. Liu, J. Wang, J. Chen, Q. Fang, and Y. Liu: Ultra-high strength TiC/refractory high-entropy-alloy composite prepared by powder metallurgy. JOM 69, 651 (2017).

C. Suryanarayana: Mechanical alloying and milling. Prog. Mater. Sci. 46, 1 (2001).

H. Huang, Y. Wu, J. He, H. Wang, X. Liu, K. An, W. Wu, and Z. Lu: Phase-transformation ductilization of brittle high-entropy alloys via metastability engineering. Adv. Mater. 29, 1701678 (2017).

H. Jiang, L. Jiang, Y.P. Lu, T.M. Wang, Z.Q. Cao, and T.J. Li: Microstructure and mechanical properties of the W–Ni–Co system refractory high-entropy alloys. Materials Science Forum. 816, 324 (2015).

H. Okamoto, P.R. Subramanian, and L. Kacprzak, eds.: Binary Alloy Phase Diagrams, 2nd ed. (ASM International, Materials Park, OH, 1990).

P. Villars, A. Prince, and H. Okamoto: Handbook of Ternary Alloy Phase Diagrams (ASM International, Materials Park, OH, USA, 1995).

H. Chen, A. Kauffmann, B. Gorr, D. Schliephake, C. Seemuller, J.N. Wagner, H.J. Christ, and M. Heilmaier: Microstructure and mechanical properties at elevated temperatures of a new Al-containing refractory high-entropy alloy Nb–Mo–Cr–Ti–Al. J. Alloys Compd. 661, 206 (2016).

N.D. Stepanov, N.Y. Yurchenko, E.S. Panina, M.A. Tikhonovsky, and S.V. Zherebtsov: Precipitation-strengthened refractory Al0.5CrNbTi2V0.5 high entropy alloy. Mater. Lett. 188, 162 (2017).

O.N. Senkov and C.F. Woodward: Microstructure and properties of a refractory NbCrMo0.5Ta0.5TiZr alloy. Mater. Sci. Eng., A 529, 311 (2011).

M.C. Gao, C.S. Carney, N. Doan, P.D. Jablonksi, J.A. Hawk, and D.E. Alman: Design of refractory high-entropy alloys. JOM 67, 2653 (2015).

N.Y. Yurchenko, N.D. Stepanov, S.V. Zherebtsov, M.A. Tikhonovsky, and G.A. Salishchev: Structure and mechanical properties of B2 ordered refractory AlNbTiVZrx (x = 0–1.5) high-entropy alloys. Mat. Sci. Eng., A 704, 82 (2017).

O.N. Senkov, S.V. Senkova, D.M. Dimiduk, C. Woodward, and D.B. Miracle: Oxidation behavior of a refractory NbCrMo0.5Ta0.5TiZr alloy. J. Mater. Sci. 47, 6522 (2012).

H. Okamoto: Phase Diagrams for Binary Alloys, 2nd ed. (ASM International, Materials Park, OH, USA, 2010).

S. Sheikh, S. Shafeie, Q. Hu, J. Ahlstrom, C. Persson, J. Vesely, J. Zyka, U. Klement, and S. Guo: Alloy design for intrinsically ductile refractory high-entropy alloys. J. Appl. Phys. 120, 164902 (2016).

Y.D. Wu, Y.H. Cai, T. Wang, J.J. Si, J. Zhu, Y.D. Wang, and X.D. Hui: A refractory Hf25Nb25Ti25Zr25 high-entropy alloy with excellent structural stability and tensile properties. Mater. Lett. 130, 277 (2014).

S-P. Wang and J. Xu: TiZrNbTaMo high-entropy alloy designed for orthopedic implants: As-cast microstructure and mechanical properties. Mater. Sci. Eng., C 73, 80 (2017).

N.N. Guo, L. Wang, L.S. Luo, X.Z. Li, Y.Q. Su, J.J. Guo, and H.Z. Fu: Microstructure and mechanical properties of refractory MoNbHfZrTi high-entropy alloy. Mater. Des. 81, 87 (2015).

H.W. Yao, J.W. Qiao, J.A. Hawk, H.F. Zhou, M.W. Chen, and M.C. Gao: Mechanical properties of refractory high-entropy alloys: Experiments and modeling. J. Alloy. Comp. 696, 1139 (2017).

L. Qi and D.C. Chrzan: Tuning ideal tensile strengths and intrinsic ductility of bcc refractory alloys. Phys. Rev. Lett. 112, 115503 (2014).

X. Yang, Y. Zhang, and P.K. Liaw: Microstructure and compressive properties of NbTiVTaAlx high entropy alloys. Procedia Eng. 36, 292 (2012).

D.X. Qiao, H. Jiang, X.X. Chang, Y.P. Lu, and T.J. Li: Microstructure and mechanical properties of VTaTiMoAlx refractory high entropy alloys. Mater. Sci. Forum 898, 638 (2017).

N.N. Guo, L. Wang, L.S. Luo, X.Z. Li, R.R. Chen, Y.Q. Su, J.J. Guo, and H.Z. Fu: Microstructure and mechanical properties of refractory high entropy (Mo0.5NbHf0.5ZrTi)BCC/M5Si3 in situ compound. J. Alloys Compd. 660, 197 (2016).

N.N. Guo, L. Wang, L.S. Luo, X.Z. Li, R.R. Chen, Y.Q. Su, J.J. Guo, and H.Z. Fu: Microstructure and mechanical properties of in-situ MC-carbide particulates-reinforced refractory high-entropy Mo0.5NbHf0.5ZrTi matrix alloy composite. Intermetallics 69, 74 (2016).

Y. Zhang, Y. Liu, Y. Li, X. Chen, and H. Zhang: Microstructure and mechanical properties of a refractory HfNbTiVSi0.5 high-entropy alloy composite. Mater. Lett. 174, 82 (2016).

Y. Liu, Y. Zhang, H. Zhang, N. Wang, X. Chen, H. Zhang, and Y. Li: Microstructure and mechanical properties of refractory HfMo0.5NbTiV0.5Six high-entropy composites. J. Alloy. Comp. 694, 869 (2017).

N.D. Stepanov, D.G. Shaysultanov, G.A. Salishchev, and M.A. Tikhonovsky: Structure and mechanical properties of a light-weight AlNbTiV high entropy alloy. Mater. Lett. 142, 153 (2015).

N.D. Stepanov, N.Y. Yurchenko, D.V. Skibin, M.A. Tikhonovsky, and G.A. Salishchev: Structure and mechanical properties of the AlCrxNbTiV (x = 0, 0.5, 1, 1.5) high entropy alloys. J. Alloy. Comp. 652, 266 (2015).

N.D. Stepanov, N.Y. Yurchenko, D.G. Shaysultanov, G.A. Salishchev, and M.A. Tikhonovsky: Effect of Al on structure and mechanical properties of AlxNbTiVZr (x = 0, 0.5, 1, 1.5) high entropy alloys. Mater. Sci. Technol. 31, 1184 (2015).

L. Lilensten, J-P. Couzinie, J. Bourgon, L. Perriere, G. Dirras, F. Prima, and I. Guillot: Design and tensile properties of a bcc Ti-rich high-entropy alloy with transformation-induced plasticity. Mater. Res. Lett. 5, 110 (2017).

C. Herrera, D. Ponge, and D. Raabe: Design of a novel Mn-based 1 GPa duplex stainless TRIP steel with 60% ductility by a reduction of austenite stability. Acta Mater. 59, 4653 (2011).

O. Grassel, L. Kruger, G. Frommeyer, and L.W. Meyer: High strength Fe–Mn–(Al,Si) TRIP/TWIP steel development—properties—applications. Int. J. Plast. 16, 1391 (2000).

F. Sun, J.Y. Zhang, M. Marteleur, T. Gloriant, P. Vermaut, D. Laille, P. Castany, C. Curfs, P.J. Jacques, and F. Prima: Investigation of early stage deformation mechanisms in a metastable β titanium alloy showing combined twinning-induced plasticity and transformation-induced plasticity effects. Acta Mater. 61, 6406 (2013).

M. Marteleur, F. Sun, T. Gloriant, P. Vermaut, P.J. Jacques, and F. Prima: On the design of new β-metastable titanium alloys with improved work hardening rate thanks to simultaneous TRIP and TWIP effects. Scripta Mater. 66, 749 (2012).

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan: Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 534, 227 (2016).

H. Chen, A. Kauffmann, S. Laube, I.C. Choi, R. Schwaiger, Y. Huang, K. Lichtenberg, F. Muller, B. Gorr, H.J. Christ, and M. Heilmaier: Contribution of lattice distortion to solid solution strengthening in a series of refractory high entropy alloys. Metall. Mater. Trans. A 49, 772 (2018).

R. Labusch: Statistical theories of solid solution hardening. Acta Metall. 20, 917 (1972).

L.A. Gypen and A. Deruyttere: The combination of atomic size and elastic modulus misfit interactions in solid solution hardening. Scripta Metall. 15, 815 (1981).

T. Suzuki: On the studies of solid solution hardening. Jpn. J. Appl. Phys. 20, 449 (1981).

I. Toda-Caraballo and P.E.J. Rivera-Diaz-Del-Castillo: Modelling solid solution hardening in high entropy alloys. Acta Mater. 85, 14 (2015).

H.A. Mooren, R. Taggart, and D.H. Polonis: A model for the prediction of lattice parameters of solid solutions. Metall. Trans. 2, 265 (1971).

H.W. Yao, J.W. Qiao, M.C. Gao, J.A. Hawk, S.G. Ma, and H.F. Zhou: MoNbTaV medium-entropy alloy. Entropy 18, 189 (2016).

S. Qiu, N. Miao, J. Zhou, Z. Guo, and Z. Sun: Strengthening mechanism of aluminum on elastic properties of NbVTiZr high-entropy alloys. Intermetallics 92, 7 (2018).

J.P. Hirth and J. Lothe: Theory of Dislocations, 2nd ed. (Krieger Publishing Co., Malabar, FL, USA, 1992).

S.I. Rao, C. Varvenne, C. Woodward, T.A. Parthasarathy, D. Miracle, O.N. Senkov, and W.A. Curtin: Atomistic simulations of dislocations in a model BCC multicomponent concentrated solid solution alloy. Acta Mater. 125, 311 (2017).

B. Gorr, M. Azim, H.J. Christ, T. Mueller, D. Schliephake, and M. Heilmaier: Phase equilibria, microstructure, and high temperature oxidation resistance of novel refractory high-entropy alloys. J. Alloys Compd. 624, 270 (2015).

B. Gorr, F. Mueller, H-J. Christ, T. Mueller, H. Chen, A. Kauffmann, and M. Heilmaier: High temperature oxidation behavior of an equimolar refractory metal-based alloy 20Nb–20Mo–20Cr–20Ti–20Al with and without Si addition. J. Alloy. Comp. 688, 468 (2016).

B. Gorr, F. Muller, M. Azim, H-J. Christ, T. Muller, H. Chen, A. Kauffmann, and M. Heilmaier: High-temperature oxidation behavior of refractory high-entropy alloys: Effect of alloy composition. Oxid. Met. 88, 339 (2017). doi: https://doi.org/10.1007/s11085-016-9696-y.

C-H. Chang, M. Titus, and J-W. Yeh: Oxidation behavior between 700 and 1300 °C of refractory TiZrNbHfTa high-entropy alloys containing aluminum. Adv. Eng. Mater., 1700948 (2018). doi: https://doi.org/10.1002/adem.201700948.

O.N. Senkov: Oxidation Behavior of Al-containing Refractory High Entropy Alloys (Air Force Research Laboratory, Wright-Patterson AFB, OH, 2012).

C.M. Liu, H.M. Wang, S.Q. Zhang, H.B. Tang, and A.L. Zhang: Microstructure and oxidation behavior of new refractory high entropy alloys. J. Alloys Compd. 583, 162 (2014).

J. Zheng, X. Hou, X. Wang, Y. Meng, X. Zheng, and L. Zheng: Isothermal oxidation mechanism of a newly developed Nb–Ti–V–Cr–Al–W–Mo–Hf alloy at 800–1200 °C. Int. J. Refract. Met. Hard Mater. 54, 322 (2016).

G.T.J. Mayo, W.H. Shepherd, and A.G. Thomas: Oxidation behaviour of niobium-chromium alloys. J. Less Common Met. 2, 223 (1960).

P. Kofstad: High Temperature Corrosion (Elsevier Applied Science, New York, NY, USA, 1988).

D.J. Young: High Temperature Oxidation and Corrosion of Metals (Elsevier, Cambridge, MA, USA, 2016).

J.H. Westbrook and D.L. Wood: “Pest” degradation in beryllides, silicides, aluminides, and related compounds. J. Nucl. Mater. 12, 208 (1964).

C.S. Giggins and F.S. Pettit: Oxidation of Ni–Cr–Al alloys between 1000° and 1200 °C. J. Electrochem. Soc. 118, 1782 (1971).

A. Poulia, E. Georgatis, A. Lekatou, and A.E. Karantzalis: Microstructure and wear behavior of a refractory high entropy alloy. Int. J. Refract. Metals Hard Mater. 57, 50 (2016).

C. Mathiou, A. Poulia, E. Georgatis, and A.E. Karantzalis: Microstructural features and dry—sliding wear response of MoTaNbZrTi high entropy alloy. Mater. Chem. Phys. 210, 126 (2018).

Y.X. Ye, C.Z. Liu, H. Wang, and T.G. Nieh: Friction and wear behavior of a single-phase equiatomic TiZrHfNb high-entropy alloy studied using a nanoscratch technique. Acta Mater. 147, 78 (2018).

S.N. Grigoriev, O.V. Sobol, V.M. Beresnev, I.V. Serdyuk, A.D. Pogrebnyak, D.A. Kolesnikov, and U.S. Nemchenko: Tribological characteristics of (TiZrHfVNbTa)N coatings applied using the vacuum arc deposition method. J. Frict. Wear 35, 359 (2014).

V. Braic, M. Balaceanu, M. Braic, A. Viadescu, S. Panseri, and A. Russo: Characterization of multi-principal-element (TiZrNbHfTa)N and (TiZrNbHfTa)C coatings for biomedical applications. J. Mech. Behav. Biomed. Mater. 10, 197 (2012).

D.B. Miracle, J.D. Miller, O.N. Senkov, C. Woodward, M.D. Uchic, and J. Tiley: Exploration and development of high entropy alloys for structural applications. Entropy 16, 494 (2014).

O.N. Senkov, J.D. Miller, D.B. Miracle, and C. Woodward: Accelerated exploration of multi-principal element alloys for structural applications. CALPHAD: Comput. Coupling Phase Diagrams Thermochem. 50, 32 (2015).

D. Miracle, B. Majumdar, K. Wertz, and S. Gorsse: New strategies and tests to accelerate discovery and development of multi-principal element structural alloys. Scripta Mater. 127, 195 (2017).

O.N. Senkov, J.W. Miller, D.B. Miracle, and C. Woodward: Accelerated exploration of multi-principal element alloys with solid solution phases. Nat. Commun. 6, 6529 (2015).

F. Zhang, C. Zhang, S.L. Chen, J. Zhu, W.S. Cao, and U.R. Kattner: An understanding of high entropy alloys from phase diagram calculations. CALPHAD: Comput. Coupling Phase Diagrams Thermochem. 45, 1 (2014).

M.C. Gao: Computational thermodynamic and kinetic modeling of high-entropy alloys and amorphous alloys. JOM 64, 828 (2012).

Thermo-Calc Software, Databases: Available at: http://www.thermocalc.com/products-services/databases/thermodynamic/.

CompuTherm Software, Databases: Available at: http://www.computherm.com/index.php?route=product/category&path=59_83.

O.N. Senkov, F. Zhang, and J.D. Miller: Phase composition of a CrMo0.5NbTa0.5TiZr high entropy alloy: Comparison of experimental and simulated data. Entropy 15, 3796 (2013).

B. Zhang, M.C. Gao, Y. Zhang, S. Yang, and S.M. Guo: Senary refractory high entropy alloy MoNbTaTiVW. Mater. Sci. Technol. 31, 1207 (2015).

H.W. Yao, J.W. Qiao, M.C. Gao, J.A. Hawk, S.G. Ma, H.F. Zhou, and Y. Zhang: NbTaV–(Ti,W) refractory high-entropy alloys: Experiments and modeling. Mater. Sci. Eng., A 674, 203 (2016).

Y.K. Mu, H.X. Liu, Y.H. Liu, X.W. Zhang, Y.H. Jiang, and T. Dong: An ab initio and experimental studies of the structure, mechanical parameters and state density on the refractory high-entropy alloy systems. J. Alloys Compd. 714, 668 (2017).

K. Wertz, J. Miller, and O. Senkov: Toward multi-principal component alloy discovery: Assessment of the CALPHAD thermodynamic databases for prediction of novel ternary alloy systems. J. Mater. Res. Published on-line 08 May 2018. https://doi.org/10.1557/jmr.2018.61 (2018).

Thermo-Calc Software. TCHEA2: TCS High Entropy Alloy Database. Available at: http://www.thermocalc.com/media/35873/tchea2_extended_info.pdf.

CompuTherm: PanHEA—Thermodynamic database for multi-component high entropy alloys. Available at: http://www.computherm.com/index.php?route=product/product&path=59_83&product_id=59.

P. Cao, X. Ni, F. Tian, L.K. Varga, and L. Vitos: Ab initio study of AlxMoNbTiV high-entropy alloys. J. Phys. Condens. Matter 27, 075401 (2015).

S.F. Pugh: XCII. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. Philos. Mag. 45, 823 (1954).

D.G. Pettifor: Theoretical predictions of structure and related properties of intermetallics. Mater. Sci. Technol. 8, 345 (1992).

H.Q. Song, F.Y. Tian, Q.M. Hu, L. Vitos, Y.D. Wang, J.A. Shen, and N.X. Chen: Local lattice distortion in high-entropy alloys. Phys. Rev. Mater. 1, 023404 (2017).

W.P. Huhn and M. Widom: Prediction of A2 to B2 phase transition in the high-entropy alloy Mo–Nb–Ta–W. JOM 65, 1772 (2013).

Y. Wang, M. Yan, Q. Zhu, W.Y. Wang, Y. Wu, X. Hui, R. Otis, S-L. Shang, Z-K. Liu, and L-Q. Chen: Computation of entropies and phase equilibria in refractory V–Nb–Mo–Ta–W high-entropy alloys. Acta Mater. 143, 88 (2018).

W.Y. Wang, S.L. Shang, Y. Wang, F. Han, K.A. Darling, Y. Wu, X. Xie, O.N. Senkov, J. Li, X.D. Hui, K.A. Dahmen, P.K. Liaw, L.J. Kecskes, and Z.K. Liu: Atomic and electronic basis for the serrations of refractory high-entropy alloys. npj Comput. Mater. 3, 23 (2017).

J.R. Davis: Metals Handbook, Desk Edition, 2nd ed. (ASM International, Metals Park, OH, USA, 1998).

D.B. Miracle: Critical assessment 14: High entropy alloys and their development as structural materials. Mater. Sci. Technol. 31, 1142 (2015).

J.R. Donoso and R.E. Reed-Hill: Slow strain rate embrittlement of niobium by oxygen. Metall. Trans. 7, 961 (1976).

C.T. Liu and H. Inoue: Internal oxidation and mechanical properties of TZM–Mo alloy. Metall. Trans. 5, 2515 (1974).

A. Kelly, W.R. Tyson, and A.H. Cotrell: Theoretical strength of crystals and the tip of a crack. Can. J. Phys. 45, 883 (1967).

A.S. Tetelman and J.A.J. McEvily: Fracture of Structural Materials (John Wiley & Sons, Inc., New York, NY, USA, 1967).

Y. Zhang, X. Yang, and P.K. Liaw: Alloy design and properties optimization of high-entropy alloys. JOM 64, 830 (2012).

S.Y. Chen, X. Yang, K.A. Dahmen, P.K. Liaw, and Y. Zhang: Microstructures and crackling noise of AlxNbTiMoV high entropy alloys. Entropy 16, 870 (2014).

Y. Zhang, Y. Liu, Y. Li, X. Chen, and H. Zhang: Microstructure and mechanical properties of a new refractory HfNbSi0.5TiVZr high entropy alloy. Mater. Sci. Forum 849, 76 (2016).

M. Todai, T. Nagase, T. Hori, A. Matsugaki, A. Sekita, and T. Nakano: Novel TiNbTaZrMo high-entropy alloys for metallic biomaterials. Scripta Mater. 129, 65 (2017).

F. Muller, B. Gorr, H-J. Christ, H. Chen, A. Kauffmann, and M. Heilmaier: Effect of microalloying with silicon on high temperature oxidation resistance of novel refractory high-entropy alloy Ta–Mo–Cr–Ti–Al. Mater. High. Temp., 35, 168 (2018). doi: https://doi.org/10.1080/09603409.2017.1389115.

M. Zhang, X. Zhou, and J. Li: Microstructure and mechanical properties of a refractory CoCrMoNbTi high-entropy alloy. J. Mater. Eng. Perform. 26, 3657 (2017).

B. Zhang, Y. Mu, M.C. Gao, W.J. Meng, and S.M. Guo: On single-phase status and segregation of an as-solidified septenary refractory high entropy alloy. MRS Commun., 7, 78 (2017). doi: https://doi.org/10.1557/mrc.2017.7.

A. Poulia, E. Georgatis, C. Mathiou, and A.E. Karantzalis: Phase segregation discussion in a Hf25Zr30Ti20Nb15V10 high entropy alloy: The effect of the high melting point element. Mater. Chem. Phys. 210, 251 (2018). doi: https://doi.org/10.1016/j.matchemphys.2017.09.059.

A.E. Karantzalis, A. Poulia, E. Georgatis, and D. Petroglou: Phase formation criteria assessment on the microstructure of a new refractory high entropy alloy. Scr. Mater. 131, 51 (2017).

A.B. Melnick and V.K. Soolshenko: Thermodynamic design of high-entropy refractory alloys. J. Alloys Compd. 694, 223 (2017).

M. Zhang, X. Zhou, X. Yu, and J. Li: Synthesis and characterization of refractory TiZrNbWMo high-entropy alloy coating by laser cladding. Surf. Coat. Technol. 311, 321 (2017).

ACKNOWLEDGMENTS

Help of Dr. T. Butler in preparation of Sec. V.A (Oxidation behavior) is greatly appreciated. The authors appreciate discussions with J-W. Yeh, S.L. Semiatin, C. Woodward, P. Liaw, G. Dirras, S. Gorsse, K. Wertz, F. Zhang, and J. Miller. We sincerely thank the many friends and colleagues who contribute to the field and have shared their insights, ideas, and results freely. Work by O.N. Senkov was supported through the Air Force on-site contract FA8650-15-D-5230 managed by UES, Inc., Dayton, Ohio.

Author information

Authors and Affiliations

Corresponding author

Additional information

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Rights and permissions

About this article

Cite this article

Senkov, O.N., Miracle, D.B., Chaput, K.J. et al. Development and exploration of refractory high entropy alloys—A review. Journal of Materials Research 33, 3092–3128 (2018). https://doi.org/10.1557/jmr.2018.153

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.153