Abstract

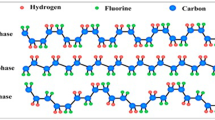

Superhydrophobic membranes have the potential to protect devices from incidental exposure to water. This paper reports on the processing of Teflon AF fluoropolymers through electrospinning. Teflon AF is difficult to electrospin due to its low dielectric constant and the low dielectric constants of the liquids in which it is soluble. The two approaches that have been utilized to produce fibers are direct electrospinning in Novec engineering liquids and core-shell electrospinning. Both methods produced superhydrophobic membranes. Fibers with an average diameter of 290 nm and average water contact angle of 151° were obtained by core-shell electrospinning. One suggested application for electrospun superhydrophobic membranes is the lithium-air battery.

Similar content being viewed by others

References

A. Marmur: The lotus effect: Super-hydrophobicity and metastability. Langmuir203517 (2004)

N.A. Patankar: On the modeling of hydrophobic contact angles on rough surfaces. Langmuir191249 (2003)

N.A. Patankar: Mimicking the lotus effect: Influence of double roughness structures and slender pillars. Langmuir208209 (2004)

L. Jiang, Y. Zhao, J. Zhai: A lotus-leaf-like superhydrophobic surface: A porous microsphere/nanofiber composite film prepared by electrohydrodynamics. Angew. Chem. Int. Ed.434338 (2004)

D. Han, A.J. Steckl: Superhydrophobic and oleophobic fibers by coaxial electrospinning. Langmuir259454 (2009)

M. Ma, R.M. Hill, G.C. Rutledge: A review of recent results on superhydrophobic materials based on micro- and nanofibers. J. Adhes. Sci. Technol.221799 (2008)

M. Ma, R.M. Hill, J.L. Lowery, S.V. Fridrikh, G.C. Rutledge: Electrospun poly(styrene-co-dimethylsiloxane) block copolymer fibers exhibiting microphase separation and superhydrophobicity. Langmuir215549 (2005)

M. Ma, Y. Mao, M. Gupta, K.K. Gleason, G.C. Rutledge: Superhydrophobic fabrics produced by electrospinning and chemical vapor deposition. Macromolecules389742 (2005)

M. Ma, M. Gupta, Z. Li, L. Zhai, K.K. Gleason, R.E. Cohen, M.F. Rubner, G.C. Rutledge: Decorated electrospun fibers exhibiting superhydrophobicity. Adv. Mater.19255 (2007)

D.H. Reneker, A.L. Yarin, H. Fong, S. Koombhongse: Bending instability of electrically charged liquid jets of polymer solutions in electrospinning. J. Appl. Phys.874531 (2000)

Z. Sun, E. Zussman, A.L. Yarin, J.H. Wendorff, A. Greiner: Compound core-shell polymer nanofibers by co-electrospinning. Adv. Mater.151929 (2003)

Product information DuPont Teflon AF Amorphous Fluoropolymers (Accessed 9 January 2010 http://www2.dupont.com/Teflon_Industrial/en_US/assets/downloads/h44587.pdf)

Electronics Markets Materials Division 3M Center St. Paul, MN (www.3M.com/novec)

3M Product Information Fluorinert Liquids for Electronics Manufacturing (Accessed 9 January 2010 http://multimedia.3m.com/mws/mediawebserver?66666UuZjcFSLXTt4xTyLx&_EVuQEcuZgVs6EVs6E666666-mws/mediawebserver?66666UuZjcFSLXTt4xTyLx&_EVuQEcuZgVs6EVs6E666666-) Novec Engineered Fluid HFE-7100 for Heat Transfer (Accessed 9 January 2010 http://multimedia.3m.com/mws/mediawebserver?66666UuZjcFSLXTtlxTcm8TtEVuQEcuZgVs6EVs6E666666-mws/mediawebserver?66666UuZjcFSLXTtlxTcm8TtEVuQEcuZgVs6EVs6E666666-)

D. Linden, T.B. Reddy Handbook of Batteries3rd ed (McGraw-Hill, New York 2002)

T. Kuboki, T. Okuyama, N. Takami: Lithium-air batteries using hydrophobic room temperature ionic liquid electrolyte. J. Power Sources146766 (2005)

R.E. Williford, J-G. Zhang: Air electrode design for sustained high-power operation of Li/air batteries. J. Power Sources1941164 (2009)

S.D. Beattie, D.M. Manolescu, S.L. Blair: High-capacity lithium-air cathodes. J. Electrochem. Soc.156A44 (2009)

R. Srikar, T. Gambaryan-Roisman, C. Steffes, P. Stephan, C. Tropea, A.L. Yarin: Nanofiber coating of surfaces for intensification of drop or spray impact cooling. Int. J. Heat Mass Transfer525814 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Scheffler, R., Bell, N.S. & Sigmund, W. Electrospun Teflon AF fibers for superhydrophobic membranes. Journal of Materials Research 25, 1595–1600 (2010). https://doi.org/10.1557/JMR.2010.0205

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2010.0205