Abstract

To eliminate the Bi segregation and interfacial embrittlement of the SnBi/Cu joints, we deliberately added some Ag or Zn elements into the Cu substrate. Then, the reliability of the SnBi/Cu–X (X = Ag or Zn) solder joints was evaluated by investigating their interfacial reactions, tensile property, and fatigue life compared with those of the SnBi/Cu and SnAg/Cu joints. The experimental results demonstrate that even after aging for a long time, the addition of the Ag or Zn elements into the Cu substrate can effectively eliminate the interfacial Bi embrittlement of the SnBi/Cu–X joints under tensile or fatigue loadings. Compared with the conventional SnAg/Cu joints, the SnBi/Cu–X joints exhibit higher adhesive strength and comparable fatigue resistance. Finally, the fatigue and fracture mechanisms of the SnBi/Cu–X solder joints were discussed qualitatively. The current findings may pave the new way for the Sn–Bi solder widely used in the electronic interconnection in the future.

Similar content being viewed by others

References

S.K. Kang, A.K. Sarkhel Lead (Pb)-free solders for electronic packaging. J. Electron. Mater. 23, 701 (1994)

M. Abtew, G. Selvaduray Lead-free solders in microelectronics. Mater. Sci. Eng., R 27, 95 (2000)

Z. Mei, J.W. Morris Jr. Characterization of eutectic Sn–Bi solder joints. J. Electron. Mater. 21, 599 (1992)

J. Glazer Microstructure and mechanical properties of Pb-free solder alloys for low-cost electronic assembly. A review. J. Electron. Mater. 23, 693 (1994)

S. Smernos, R. Strauss Low-temperature soldering. Electrochem. Commun. 57, 148 (1982)

Z. Mei, F. Hua, J. Glazer, C.C. Key Low temperature soldering 21st IEEE/CPMT International Electronics Manufacturing Technology Symposium Proceedings (IEMT Symposium, Austin, TX 1997) 463

P.L. Liu, J.K. Shang Interfacial segregation of bismuth in copper/tin–bismuth solder interconnect. Scr. Mater. 44, 1019 (2001)

P.L. Liu, J.K. Shang Interfacial embrittlement by bismuth segregation in copper/tin–bismuth Pb-free solder interconnect. J. Mater. Res. 16, 1651 (2001)

Q.S. Zhu, Z.F. Zhang, Z.G. Wang, J.K. Shang Inhibition of interfacial embrittlement at SnBi/Cu single crystal by electrodeposited Ag film. J. Mater. Res. 23, 78 (2008)

P.L. Liu, J.K. Shang Fracture of SnBi/Ni(P) interfaces. J. Mater. Res. 20, 818 (2005)

H.F. Zou, Q.K. Zhang, Z.F. Zhang Eliminating interfacial segregation and embrittlement of bismuth in SnBi/Cu joint by alloying Cu substrate. Scr. Mater. 61, 308 (2009)

V.J. Keast, A.L. Fontaine, J.D. Plessis Variability in the segregation of bismuth between grain boundaries in copper. Acta Mater. 55, 5149 (2007)

G. Duscher, M.F. Chisholm, U. Alber, M. Rühle Bismuth-induced embrittlement of copper grain boundaries. Nat. Mater. 3, 621 (2004)

R. Schweinfest, A.T. Paxton, M.W. Finnis Bismuth embrittlement of copper is an atomic size effect. Nature 432, 1008 (2004)

S.Q. Liu, W.Q. Sun Liquids of Ag–Cu–Bi system. Acta Metall. Sinica 24, 376 (1988)

X. Deng, G. Piotrowski, J.J. Williams, N. Chawla Influence of initial morphology and thickness of Cu6Sn5 and Cu3Sn intermetallics on growth and evolution during thermal aging of Sn–Ag solder/Cu joints. J. Electron. Mater. 32, 1403 (2003)

M. He, Z. Chen, G.J. Qi Solid state interfacial reaction of Sn–37Pb and Sn–3.5Ag solders with Ni–P under bump metallization. Acta Mater. 52, 2047 (2004)

J.W. Yoon, J.H. Lim, H.J. Lee, J. Joo, S.B. Jung, W.C. Moon Interfacial reactions and joint strength of Sn–37Pb and Sn–3.5Ag solders with immersion Ag-plated Cu substrate during aging at 150 °C. J. Mater. Res. 21, 3196 (2006)

H.F. Zou, Q.K. Zhang, H.J. Yang, Z.F. Zhang Mater. Sci. Eng., A (2010 in press )

H.T. Lee, M.H. Chen, H.M. Jao, T.L. Liao Influence of interfacial intermetallic compound on fracture behavior of solder joints. Mater. Sci. Eng., A 358, 134 (2003)

H.F. Zou, Z.F. Zhang Ductile-to-brittle transition induced by increasing strain rate in Sn–3Cu/Cu joints. J. Mater. Res. 23, 1614 (2008)

J.W. Yoon, S.B. Jung Interfacial reactions and shear strength on Cu and electrolytic Au/Ni metallization with Sn–Zn solder. J. Mater. Res. 21, 1590 (2006)

P.J. Shang, Z.Q. Liu, D.X. Li, J.K. Shang TEM observations of the growth of intermetallic compounds at the SnBi/Cu interface. J. Electron. Mater. 38, 2579 (2009)

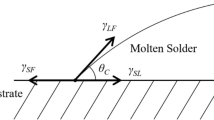

K. Tojima Wetting Characteristics of Lead-Free Solders, Senior Project Report (Materials Engineering Department, San Jose State University 1999)

Y. Yamagishi, M. Ochiai, H. Ueda, T. Nakanishi, M. Kitazima Pb-free solder of Sn-58Bi improved with Ag Proceedings of the Ninth International Microelectronics Conference (Omiya Japan 1996) 252

Q.K. Zhang, Z.F. Zhang unpublished work

Q.K. Zhang, Z.F. Zhang Fracture mechanism and strength-influencing factors of Cu/Sn–4Ag solder joints aged for different times. J. Alloys Compd. 485, 853 (2009)

P.J. Shang, Z.Q. Liu, D.X. Li, J.K. Shang Bi-induced voids at the Cu3Sn/Cu interface in eutectic SnBi/Cu solder joints. Scr. Mater. 58, 409 (2008)

W.J. Tomlinson, I. Collier The mechanical properties and microstructures of copper and brass joints soldered with eutectic tin bismuth solder. J. Mater. Sci. 22, 1835 (1987)

Q.K. Zhang, Q.S. Zhu, H.F. Zou, Z.F. Zhang Fatigue fracture mechanisms of Cu/lead-free solders interfaces. Mater. Sci. Eng. A (2009 DOI: 10.1016/j.msea.2009.10.040 )

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Q., Zou, H. & Zhang, ZF. Improving tensile and fatigue properties of Sn–58Bi/Cu solder joints through alloying substrate. Journal of Materials Research 25, 303–314 (2010). https://doi.org/10.1557/JMR.2010.0035

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2010.0035