Abstract

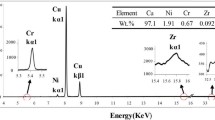

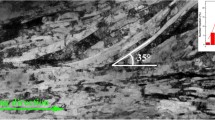

In this study, we synthesized Cu–Zr binary alloys reinforced with an ultrafine eutectic microstructure. The alloys consisted of alternating layers of a hard superlattice phase and a ductile Cu phase with a very fine interlamellar spacing of ∼60 nm. The superlattice phase enhanced the strength of the alloys while the laminated composite structure helped improve their plasticity, making their mechanical properties comparable to those of the earlier reported high strength alloys. This paper discusses the fundamental microstructural aspects that influence the mechanical properties of these alloys.

Similar content being viewed by others

References

Y. Wang, M. Chen, F. Zhou E. Ma: High tensile ductility in a nanostructured metal. Nature 419, 912 2002

C.Y. Lim, S.Z. Han S.H. Lee: Formation of nano-sized grains in Cu and Cu–Fe–P alloys by accumulative roll bonding process. Met. Mater. Int. 12, 225 2006

A.L. Greer: Metallic glasses. Science 267, 1947 1995

M. Takeyama C.T. Liu: Effect of grain size on yield strength of Ni3Al and other alloys. J. Mater. Res. 3, 665 1988

T. Ohmura, K. Tsuzaki, N. Tsuji N. Kamikawa: Matrix strength evaluation of ultra-fine grained steel by nanoindentation. J. Mater. Res. 19, 347 2004

J.R. Trelewicza C.A. Schuh: The Hall–Petch breakdown in nanocrystalline metals: A crossover to glass-like deformation. Acta Mater. 55, 5948 2007

C.M. Lee, S.W. Chae, H-J. Kim J.C. Lee: Role of nanocrystals on the plasticity of amorphous alloy. Met. Mater. Int. 13, 191 2007

H.Q. Li, L. Li, C. Fan, H. Choo P.K. Liaw: Nanocrystalline coating enhanced ductility in a Zr-based bulk metallic glass. J. Mater. Res. 22, 508 2007

K.H. Kim, H.J. Kim J-C. Lee: Effect of a minor element with a large mixing enthalpy difference on the plasticity of amorphous alloys. J. Mater. Res. 22, 2558 2007

K.E. Knipling, D.C. Dunand D.N. Seidman: Precipitation evolution in Al–Zr and Al–Zr–Ti alloys during isothermal aging at 375–425 °C. Acta Mater. 56, 114 2008

Z.G. Li, X. Hui, C.M. Zhang, M.L. Wang G.L. Chen: Strengthening and toughening of Mg–Cu–(Y, Gd) bulk metallic glasses by minor addition of Be. Mater. Lett. 61, 5018 2007

Z. Li L.M. Peng: Microstructural and mechanical characterization of Nb-based in situ composites from Nb–Si–Ti ternary system. Acta Mater. 55, 6573 2007

L. Zhou, G. Liu, Z. Han K. Lu: Grain size effect on wear resistance of a nanostructured AISI52100 steel. Scripta Mater. 58, 445 2007

J.C. Lee, Y.C. Kim, J.P. Ahn, H.S. Kim, S.H. Lee B.J. Lee: Deformation-induced nanocrystallization and its influence on work hardening in a bulk amorphous matrix composite. Acta Mater. 52, 1525 2004

G. He, J. Eckert, W. Loser L. Schultz: Novel Ti-base nanostructure–dendrite composite with enhanced plasticity. Nat. Mater. 2, 33 2003

C.C. Hays, C.P. Kim W.L. Johnson: Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions. Phys. Rev. Lett. 84, 2901 2000

J. Eckert, J. Das, G. He, M. Calin K.B. Kim: Ti-base bulk nanostructure-dendrite composites: Microstructure and deformation. Mater. Sci. Eng., A 449, 24 2007

J. Eckert, U. Kuhn, J. Das, S. Scudino N. Radtke: Nanostructured composite materials with improved deformation behavior. Adv. Eng. Mater. 7, 587 2005

D.V. Louzguine-Luzgin, L.V. Louzguina-Luzgina, H. Kato A. Inoue: Investigation of high strength metastable hypereutectic ternary Ti–Fe–Co and quaternary Ti–Fe–Co–(V, Sn) alloys. J. Alloys Compd. 434, 32 2007

J. Das, K.B. Kim, F. Baier, W. Loser, A. Gebert J. Eckert: Bulk ultra-fine eutectic structure in Ti–Fe-base alloys. J. Alloys Compd. 434, 28 2007

D.V. Louzguine, H. Kato A. Inoue: High strength and ductile binary Ti–Fe composite alloy. J. Alloys Compd. 384, L1 2004

S.J. Lee, S.W. Lee, K.H. Kim, J.H. Hahn J.C. Lee: A high strength Cu-based alloy containing superlattice structures. Scr. Mater. 56, 457 2007

X.C. He, H. Wang, H.S. Liu Z.P. Jin: Thermodynamic description of the Cu–Ag–Zr system. Calphad 30, 367 2006

A. Inoue: Stabilization and high strain-rate superplasticity of metallic supercooled liquid. Mater. Sci. Eng., A 267, 171 1999

K.C. Thompson-Russell J.W. Edington: Electron Microscope Specimen Preparation Techniques in Materials Science N.V. Philips Gloeilampenfabrieken Eindhoven 1977 37

L.C. Zhang, J. Das, H.B. Lu, C. Duhamel, M. Calin J. Eckert: High strength Ti–Fe–Sn ultrafine composites with large plasticity. Scripta Mater. 57, 101 2007

D.B. Williams C.B. Carter: Transmission Electron Microscopy: A Textbook for Materials Science Plenum Press New York 1996 478

B.J. Lee, J.H. Shim M.I. Baskes: Semiempirical atomic potentials for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, Al, and Pb based on first and second nearest-neighbor modified embedded atom method. Phys. Rev. B: Condens. Matter 68, 144112 2003

Y.M. Kim, B.J. Lee M.I. Baskes: Modified embedded-atom method interatomic potentials for Ti and Zr. Phys. Rev. B: Condens. Matter 74, 014101 2006

J. Eckert, J. Das, K.B. Kim, F. Baier, M.B. Tang, W.H. Wang Z.F. Zhang: High strength ductile Cu-base metallic glass. Intermetallics 14, 876 2006

K.H. Kim, S.W. Lee, J.P. Ahn, E. Fleury, Y.C. Kim J.C. Lee: A Cu-based amorphous alloy with a simultaneous improvement in glass forming ability and plasticity. Met. Mater. Int. 13, 21 2007

E.S. Park D.H. Kim: Phase separation and enhancement of plasticity in Cu–Zr–Al–Y bulk metallic glasses. Acta Mater. 54, 2597 2006

G. He, W. Loser J. Eckert: In situ formed Ti–Cu–Ni–Sn–Ta nanostructure–dendrite composite with large plasticity. Acta Mater. 51, 5223 2003 APPENDIX

Acknowledgment

This research was supported by grants from the Next Generation Technology Development Projects of Korea Institute of Industrial Technology, Korea.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The structure of the superlattice phase was identified by HRTEM, HR simulation, and molecular statistics. Considering that the superlattice phase is based on the structure of Cu5Zr intermetallic compound (fcc, F¯43m), structural characterization was performed using crystallographic and thermodynamic data for Cu5Zr. The HRTEM observation was interpreted using JEMS simulation (Electron Microscopy Software, JAVA version, JEMS, EMS). In addition, the enthalpy of formation (ΔHf) was calculated by a modified embedded-atom method (MEAM) interatomic potential for pure Cu28 and Zr.29 The most stable atomic configuration of the superlattice phase was identified by calculating Zr atomic positions using the various enthalpies of formation by substituting each Cu site in Cu5Zr with a Zr atom.

Figure A1 shows HRTEM micrographs of the superlattice observed at three zone axes corresponding to (a) [010], (b) [130], and (c) [031], respectively, and (d) a Kikuchi map of the Cu5Zr phase. The map makes possible evaluation of the orientation relationship of the interposed plane in the superlattice. From the HRTEM image recorded at the zone axis of [010] in Fig. A1(a), a typical superlattice fringe can be observed with a modulated contrast perpendicular to [001]. Also, the HRTEM images were recorded at the zone axes corresponding to [130] and [031]. Figures A1(b) and A1(c) were acquired at the zone axes of [130] and [031], respectively. In Figs. A1(b) and A1(c), the modulated contrast was still observable after tilting around the [001] axis, whereas it disappeared when tilting around the [100] axis. This suggests that the superlattice plane was interposed only in the [001] direction, even though the cubic system has three equivalent directions for 〈100〉. From the structural characterization of the HRTEM images and diffraction patterns, the specific growth direction of the superlattice corresponds to the [001] direction.

Figure A2(a) shows HRTEM micrographs of the superlattice phase observed at the zone axis of [001], showing a typical superlattice fringe with the modulated contrast. Hereafter, the bright and dark layers in Fig. A2(a) are referred to as layer I and layer II, respectively. To investigate the chemical composition of the modulated layer in the superlattice phase, a line profile across layers I and II was examined at the zone axis of [010] using electron energy loss spectroscopy (EELS), as shown in the Fig. A2(b). The EELS spectra shows that layer I has a lower Cu content than layer II. Considering that the basic structure of the superlattice is based on the Cu5Zr intermetallic compound, a lower Cu content in layer I is thought to be due to the substitution of Cu with Zr.

Figure A3(a) shows a magnified HRTEM micrograph near the interface of layers I and II, as indicated by the broken rectangle in Fig. A2(a), while Fig. A3(b) is the HRTEM image simulated under acceleration voltage of 200 keV, spherical aberration of Cs = 1.2 mm, energy spread of 0.6 eV, and defocus of −64 nm. The numbers marked on the calculated HRTEM image indicate the atomic sites of Cu that can be substituted by Zr in order to construct the superlattice phase. Enthalpies of formation were calculated using molecular statistics for each position of Zr in Fig. A3(b). The calculation result shows that the enthalpy of formation for fictitious atomic site 1 was −12.890 kJ/mol of atoms, while other positions had positive values. This fact reflects that the substitution of Cu atom in site 1 by a Zr atom induces the structural stability of the superlattice phase due to the minimum enthalpy of formation. Therefore, it is believed that the superlattice phase is a cubic system with the Cu atomic site 1 replaced by a Zr atom. Although this superlattice phase is in the same space group with Cu5Zr and its atomic position is identical to Cu5Zr phase, they—i.e., the Cu5Zr-based super lattice and the Cu5Zr intermetallic compound—are composed of totally different crystal structures. The specific atomic sites of Cu atomic position [(0.25, 0.75, 0.75), (0.75, 0.75, 0.25)] in Cu5Zr, are periodically replaced by Zr atoms, and then the atomic sequence is finally changed. Considering the above experimental results, HR simulation was performed. As shown in Fig. A4, the simulated HR image and the real image show the same superlattice fringe with the modulated contrast. To the best of our knowledge, the superlattice phase is a new phase, which has not yet been reported in the Cu–Zr equilibrium phase diagram.23

(a) Magnified view of the broken rectangle indicated in Fig. A2(a).(b) Simulated HR image of the same region, showing the atomic positions of Cu and Zr.

Rights and permissions

About this article

Cite this article

Kim, KH., Ahn, JP., Lee, JH. et al. High-strength Cu–Zr binary alloy with an ultrafine eutectic microstructure. Journal of Materials Research 23, 1987–1994 (2008). https://doi.org/10.1557/JMR.2008.0245

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2008.0245