Abstract

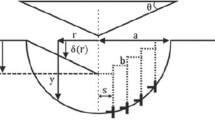

The indentation size effect of pure iron samples with various pre-plastic tensile strains has been experimentally investigated and analyzed. With the increase in the strain, the indentation size effect of iron samples becomes weak, accompanied by the multiplication of the statistically stored dislocations. All of the hardness (H) versus indentation depth (h) curves fit the strain-gradient plasticity model for indentation of Nix and Gao well. Two fitting parameters, the hardness in the limit of infinite depth (H0) and the characteristic length (h*), were obtained for each curve. The hardness (H0) of iron samples can also be estimated as the microhardness (H) at a very large depth, h ≅ 10h*. Both the fitted H0 and the measured H0′ increase linearly with the tensile yield stress σy of iron samples, indicating a dependence of H0 on the statistically stored dislocation density through σy. Furthermore, 1/√h* shows a linear increase with the tensile yield stress σy, which also agrees qualitatively with the general prediction of the Nix and Gao theory. Therefore, our experiments and analysis demonstrate that the strain-gradient plasticity model for indentation of Nix and Gao can interpret the indentation size effect with satisfied precision.

Similar content being viewed by others

References

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

L.M. Qian, X.D. Xiao, Q.P. Sun and T.X. Yu: Anomalous relationship between hardness and wear properties of a superelastic nickel–titanium alloy. Appl. Phys. Lett. 84, 1076 (2004).

L.M. Qian, F. Tian and X.D. Xiao: Tribological properties of self-assembled monolayers and their substrates under various humid environments. Tribol. Lett. 15, 169 (2003).

S.M. Spearing: Materials issues in microelectromechanical systems (MEMS). Acta Mater. 48, 179 (2000).

L.M. Qian, G. Luango and E. Perez: Thermally activated lubrication with alkanes: The effect of chain length. Europhys. Lett. 61, 268 (2003).

X.D. Xiao and L.M. Qian: Investigation of humidity-dependent capillary force. Langmuir 16, 8153 (2000).

L.M. Qian, M. Li, Z.R. Zhou, H. Yang and X.Y. Shi: Comparison of nano-indentation hardness and micro hardness. Surf. Coat. Technol. 195, 264 (2005).

L.E. Samuels: Microindentation in Metals, ASTM STP 889 (Philadelphia, PA, 1986), pp. 5–25.

P.M. Sargent: Use of the Indentation Size Effect on Microhardness for Materials Characterization, ASTM STP 889 (Philadelphia, PA, 1986), pp. 160–174.

H. Li, A. Ghosh, Y.H. Han and R.C. Bradt: The frictional component of the indentation size effect in low load microhardness testing. J. Mater. Res. 8, 1028 (1993).

Q. Ma and D.R. Clarke: Size-dependent hardness in silver single crystals. J. Mater. Res. 10, 853 (1995).

F. Froehlich, P. Grau and W. Wrellmann: Performance and analysis of recording microhardness tests. Phys. Status Solidi 42, 79 (1977).

W.D. Nix and H. Gao: Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 46, 411 (1998).

M. Atkinson: Origin of the indentation size effect in indentation of metals. Int. J. Mech. Sci. 33, 843 (1991).

N.A. Stelmashenko, M.G. Walls, L.M. Brown and Y.V. Milman: Microindentation on W and Mo oriented single crystals: An STM study. Acta. Metall. Mater. 41, 2855 (1993).

W.J. Poole, M.F. Ashby and N.A. Fleck: Microhardness of annealed and work-hardened copper polycrystals. Scr. Metall. Mater. 34, 559 (1996).

A.A. Elmustafa and D.S. Stone: Indentation size effect: Large grained aluminum versus nanocrystalline aluminum-zirconium alloys. J. Mech. Phys. Solids 51, 357 (2003).

W.W. Gerberich, N.I. Tymiak, J.C. Grunlan, M.F. Horstemeyer and M.I. Baskes: Interpretations of indentation size effects. J. Appl. Mech.-Trans. ASME 69, 433 (2002).

N.I. Tymiak, D.E. Kramer, D.F. Bahr, T.J. Wyrobek and W.W. Gerberich: Plastic strain and strain gradients at very small indentation depths. Acta Mater. 49, 1023 (2001).

H. Gao, Y. Huang and W.D. Nix: Modeling plasticity at the micron scale. Naturwissenschaften 86, 507 (1999).

J.D. Swadener, A. Misra, R.G. Hoagland and M. Nastasi: A mechanistic description of combined hardening and size effects. Scr. Mater. 47, 343 (2002).

G. Feng and W.D. Nix: Indentation size effect in MgO. Scr. Mater. 51, 599 (2004).

D. Tabor: The Hardness of Metals (Clarendon Press, Oxford, England, 1951).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qian, L., Yang, H., Zhu, M. et al. Experimental verification of the strain-gradient plasticity model for indentation. Journal of Materials Research 20, 3150–3156 (2005). https://doi.org/10.1557/JMR.2005.0395

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2005.0395