Abstract

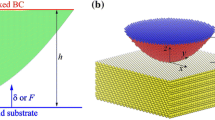

By using molecular dynamics simulations, we have accurately determined the true contact area during plastic indentation of materials under an applied in-plane stress. We found that the mean pressure calculated from the true contact area varied slightly with applied pre-stress with higher values in compression than in tension and that the modulus calculated from the true contact area is essentially independent of the press-stress level in the substrate. These findings are largely consistent with the findings of Tsui, Pharr, and Oliver. On the other hand, if the contact area is estimated from approximate formulae, the contact area is underestimated and shows a strong dependence on the pre-stress level. When it is used to determine mean pressure and modulus, the empirically determined area leads to large errors. Our simulations demonstrate that this phenomenon, first reported for macroscale hardness measurements dating back to 1932, also exists at the nanometer-scale contact areas, apparently scaling over 10 orders of magnitude in contact area, from ~mm2 to ~100 nm2.

Similar content being viewed by others

References

M.F. Doerner and W.D. Nix: A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1, 601 (1986).

O.A. Shenderova, J.P. Mewkill, and D.W. Brenner: Nanoindentation as a probe of nanoscale residual stress. Atomistic Simulation Results. Molecular Simulation 25, 81 (2000).

K.F. Jarausch, J.D. Kiely, J.E. Houston, and P.E. Russell: Defectdependent elasticity: Nanoindentation as a probe of stress state. J. Mater. Res. 15, 1693 (2000).

J.J. Gilman: In The Science of Hardness Testing and Its Research Applications, edited by J.H. Westbrook and H. Conrad (American Society for Metals, Metals Park, OH, 1973), pp. 51–74.

J.B. Pethica: In Ion Implantation into Metals, edited by V. Asheworth, W. Grant, and R. Procter (Pergamon Press, Oxford, U.K., 1982), pp. 147–156.

J.L. Loubet, J.M. Georges, O. Marchesini, and G. Meille: Vickers indentation curves of magnesium oxide (MgO). J. Tribology 106, 43 (1984).

D. Newey, M.A. Wilkins, and H.M. Pollock: An ultra-low-load penetration hardness tester. J. Phys. E: Sci. Instrum. 15, 119 (1982).

D. Stone, W.R. LaFontaine, P. Alexopoulos, T-W. Wu, and Che-Yu Li: An investigation of hardness and adhesion of sputterdeposited aluminum on silicon by utilizing acontinuous indentation test. J. Mater. Res. 3, 141 (1988).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

J.S. Field and M.V. Swain: A simple predictive model for spherical indentation. J. Mater. Res. 8, 297 (1993).

S. Kokubo: Science Reports of the Tohoku Imperial University. 21, 256 (1932).

G. Sines and R. Carlson: Hardness measurements for determination of residual stresses. ASTM Bulletin 180, 35 (1952).

G.U. Oppel amd P.W. Hill: Strain measurements of the Root of Cracks and Notches, Proceeding of the Society for Experimental Stress Analysis 21, 206 (1964).

T.R. Simes, S.G. Mellor, and D.A. Hills: A note on the influence of residual-stress on measured hardness. J. Strain Analysis 19, 135 (1984).

W.R. LaFontaine: C.A. Paszkiet, M.A. Korhonen, and Che-Yu Li: Residual stress measurements of thin aluminum metallizations by continuous indentation and x-ray stress measurement techniques. J. Mater. Res. 6, 2084 (1991).

T.Y. Tsui, W.C. Oliver, and G.M. Pharr: Influences of stress on the measurement of mechanical properties using nanoindentation: Part I. Experimental studies in an aluminum alloy. J. Mater. Res. 11, 752 (1996).

A. Bolshakov, W.C. Oliver, and G.M. Pharr: Influences of stress on the measurement of mechanical properties using nanoindentation: Part II. Finite element simulations. J. Mater. Res. 11, 760 (1996).

X. Chen and J.J. Vlassak: Numerical study on the measurement of thin film mechanical properties by means of nanoindentation. J. Mater. Res. 16, 2974 (2001).

S.J. Plimpton and B.A. Hendrickson: Parallel molecular dynamics with the embedded atom method, in Materials Theory and Modelling, edited by J. Broughton, P. Bristowe, and J. Newsam (Mater. Res. Soc. Symp. Proc. 291, Pittsburgh, PA, 1993), p. 37.

M.S. Daw and M.I. Baskes: Embedded atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 29, 6443 (1984).

S.M. Foiles, M.I. Baskes, and M.S. Daw: Embedded atom method functions for the FCC metals Cu, Ag, Au, Ni, Pd, Pt and their alloys. Phys. Rev. B 33, 7983 (1986).

C.L. Kelchner, S.J. Plimpton, and J.C. Hamilton: Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 58, 11085 (1998).

J.A. Zimmerman, C.L. Kelchner, P.A. Klein, J.C. Hamilton, and S.M. Foiles: Surface step effects on nanoindentation. Phys. Rev. Lett. 87, 165507 (2001).

E.T. Lilleodden, J.A. Zimmerman, S.M. Foiles, and W.D. Nix: Atomistic simulation of elastic deformation and dislocation nucleation during nanoindentation, J. Mech. and Phys. Solids 51, 901 (2003).

E.T. Lilleodden: In Indentation induced plasticity of thin metal films. Ph.D. Thesis, Department of Materials Science and Engineering, Stanford University, Stanford, California, 2001.

R. Kubo: Fluctuation-dissipation theorem. Rep. Prog. Theor. Phys. 33, 425 (1965).

G.M. Pharr and A. Bolshakov: Understanding nanoindentation unloading curves. J. Mater. Res. 17, 2660 (2002).

J. Frenkel: Z. Phys. 37, 572 (1926).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Schall, J.D., Brenner, D.W. Atomistic simulation of the influence of pre-existing stress on the interpretation of nanoindentation data. Journal of Materials Research 19, 3172–3180 (2004). https://doi.org/10.1557/JMR.2004.0410

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2004.0410