Abstract

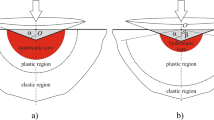

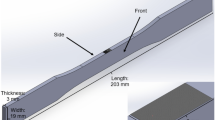

A frequent application of the nanoscratch technique is to estimate hardness of ultrathin films when substrate effects are encountered with the nanoindentation technique. A model based on the work of Goddard and Wilman, which assumes a rigid-plastic behavior of the deformed surfaces, is commonly used for the determination of hardness from scratch tests, yet it overestimates the hardness of materials by as much as a factor of three at very shallow indentation depths on the order of 1–10 nm. The Goddard and Wilman model was extended in this paper to include the effects of the component of the shear stress tangential to the meridianal plane and the elastic recovery of the plastically deformed surfaces assuming elastic-perfectly-plastic material behavior. The proposed model was subsequently verified by performing nanoscratch experiments on fused quartz, which is homogeneous and isotropic with no known surface layers and with known hardness. The hardness was calculated using both the model based on the work of Goddard and Wilman and the extended model. The hardness calculated using the extended model was in very close agreement with the accepted value of bulk hardness of fused quartz over the range of scratch depths tested, showing the importance of the effects of elastic recovery and interfacial shear stress. The model was further verified for the case of a pure aluminum sample and the native thin film coating of alumina that forms on the surface upon air exposure.

Similar content being viewed by others

References

M.A. Haque and M.T.A. Saif, Exp. Mech. 42, 123 (2002).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

M.F. Doerner and W.D. Nix, J. Mater. Res. 1, 601 (1986).

A.K. Bhattacharya and W.D. Nix, Int. J. Solids Struct. 24, 1287 (1988).

X. Chen and J.J. Vlassak, J. Mater. Res. 16, 2974 (2001).

B. Bhushan, V.S. Williams, and R.V. Shack, ASME J. of Tribol. 110, 563 (1988).

Y. Tsukamato, H. Yamaguchi, and M. Yanagisawa, Thin Solid Films 154, 171 (1987).

F. Mohs, Grundriss der Mineralogie, (1824), English Translation by W. Haidinger, Treatise of Mineralogy (Constable, Edinburgh, Scotland, 1825).

J. Williams, Tribol. Int. 29, 675 (1996).

X. Li and B. Bhushan, J. Mater. Res. 14, 2328 (1999).

R. Consiglio, N.X. Randall, B. Bellaton, and J. von Stebut, Thin Solid Films 332, 151 (1998).

B. Bhushan, Handbook of Micro/Nanotribology, 2nd ed. (CRC, Boca Raton, FL, 1999).

B. Bhushan, K. Gupta, and M. Azarian, Wear 181–183, 743 (1995).

E.R. Kral, K. Komvopoulos, and D.B. Bogy, ASME J. Tribol. 118, 1 (1996).

N. Maan and A. Broese Van Groenou, Wear 42, 365 (1977).

K. Komvopoulos, N. Saka, and N.P. Suh, ASME J. Tribol. 108, 301 (1986).

T.C. Buttery and J.F. Archard, Proc. Inst. Mech. Eng. 185, 537 (1971).

C.A. Brookes, P. Green, P.H. Harrison, and B. Moxley, J. Phys. D: Appl. Phys. 5, 1284 (1972).

T.A. Adler and R.P. Walters, Wear 162–164, 713 (1993).

A. Rodrigo, P. Perillo, and H. Ichimura, Surf. Coat. Technol. 124, 87 (2000).

H. Ichimura and A. Rodrigo, Surf. Coat. Technol. 126, 152 (2000).

A. Rodrigo and H. Ichimura, Surf. Coat. Technol. 148, 8 (2001).

H. De Beurs, G. Minholts, and J.Th.M. De Hosson, Wear 132, 59 (1989).

Friction, Lubrication and Wear Technology, ASM Handbook, Vol. 18 (ASM International, New York, 1992).

K. Li, Y. Shapiro, and J.C.M. Li, Acta Mater. 46, 5569 (1998).

B.J. Briscoe, A. Delfino, and E. Pellilo, Wear 225–229, Part 1, 319 (1999).

M.C. Shaw, Mech. Chem. Eng. Trans. I. E. Aust., MC8, 73 (1972).

J. Goddard and H. Wilman, Wear 5, 114 (1962).

K. Komvopoulos, N. Saka, and N.P. Suh, ASME J. Tribol. 107, 452 (1985).

Nano-Scratch User Manual, Hysitron, Inc., Minneapolis, MN.

N.A. Stillwell and D. Tabor, Proc. Phys. Soc. London 78, 169 (1961).

Z. Li, Y-T. Cheng, H.T. Yang, and S. Chandrasekar, Surf. Coat. Technol. 154, 124 (2002).

V. Jardet, H. Zahouni, J.L. Loubet, and T.G. Mathia, Wear 218, 8 (1998).

J. Bucaille, E. Felder, and G. Hochstetter, Wear 249, 422 (2001).

K.L. Johnson, J. Mech. Phys. Solids 18, 145 (1970).

J. Boussinesq, Application des potentials a l’etude de l’equilibre du movement des solides elastiques (Gauthier-Villars, Paris, France, 1885).

A.E.H. Love, A Treatise on the Mathematical Theory of Elasticity (Dover Publications, New York, 1944).

K.L. Johnson, Contact Mechanics (Cambridge University Press, Cambridge, U.K., 1985).

M.T.A. Saif, S. Zhang, M.A. Haque, and J. Hsia, Acta Mater. 50, 2779 (2002).

J.F. Shackelford and W. Alexander, Materials Science and Engineering Handbook (CRC Press, Boca Raton, FL, 2001).

R. Saha and W.D. Nix, Acta Mater. 50, 23 (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tayebi, N., Conry, T.F. & Polycarpou, A.A. Determination of hardness from nanoscratch experiments: Corrections for interfacial shear stress and elastic recovery. Journal of Materials Research 18, 2150–2162 (2003). https://doi.org/10.1557/JMR.2003.0301

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2003.0301