Abstract

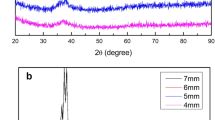

Formation of bulk Fe-based glassy alloys with high corrosion resistance was succeeded in the Fe75–x–yCrxMoyC15B10 alloy system. A large temperature interval of supercooled liquid region (ΔTx) of 40–90 K was obtained over a wide composition range for the Fe75?x–yCrxMoyC15B10 alloys. The Fe75–x–yCrxMoyC15B10 alloys were prepared in a bulk glassy form with diameters of 1.0–2.5 mm by copper mold casting. The bulk glassy Fe75–x–yCrxMoyC15B10 alloys exhibited high corrosion resistance in 1 N HCl solution. The glassy alloys containing Cr were spontaneously passivated with a wide passive region before the transpassive dissolution of Cr. The passive current density decreased significantly with an increase of alloying Cr content, indicating that the addition of Cr was effective on enhancing the corrosion resistance. Excess addition of Mo for replacing Fe in the present alloys was detrimental for the corrosion resistance.

Similar content being viewed by others

References

A. Inoue, K. Ohtera, K. Kitta, and T. Masumoto, J. Appl. Phys. 27, L2248 (1988).

A. Inoue, T. Zhang, and T. Masumoto, Mater. Trans. JIM 30, 965 (1989).

A. Inoue, T. Zhang, and T. Masumoto, Mater. Trans. JIM 31, 177 (1990).

A. Peker and W.L. Johnson, Appl. Phys. Lett. 63, 2342 (1993).

A. Inoue, Y. Shinobara, and G.S. Gook, Mater. Trans. JIM 36, 1427 (1995).

A. Inoue, T. Zhang, and A. Takeuchi, Appl. Phys. Lett. 71, 464 (1997).

A. Inoue and X.M. Wang, Acta Mater. 48, 1383 (2000).

M. Naka, K. Hashimoto, and T. Masumoto, J. Jpn. Inst. Metals 38, 835 (1974).

M. Naka, K. Hashimoto, and T. Masumoto, Sci. Rep. RITU A26, 283 (1977).

M. Naka, K. Hashimoto, A. Inoue, and T. Masumoto, J. Noncryst. Solids 31, 347 (1979).

K. Asami, K. Kawashima, and K. Hashimoto, Mater. Sci. Eng. 99, 475 (1988).

H. Habazaki, A. Kawashima, K. Asami, and K. Hashimoto, Corros. Sci. 33, 225 (1992).

X.Y. Li, E. Akiyama, H. Habazaki, A. Kawashima, K. Asami, and K. Hashimoto, Corros. Sci. 41, 1095 (1999).

A. Inoue and J.S. Gook, Mater. Trans. JIM 36, 1282 (1995).

A. Inoue, T. Zhang, T. Itoi, and A. Takeuchi, Mater. Trans. JIM 38, 359 (1997).

A. Inoue, Mater. Trans. JIM 36, 866 (1995).

Metals Databook, edited by Japan Inst. Metals (Maruzen, Tokyo, Japan, 1993), pp. 1–8.

F.R. de Boer, R. Boom, W.C.M. Mattens, A.R. Miedema, and A.K. Niessen, Cohesion in Metals (North-Holland, Amsterdam, The Netherlands, 1989), pp. 103–637.

S.J. Pang, T. Zhang, K. Asami, and A. Inoue, Corros. Sci., in press.

K. Asami, M. Naka, K. Hashimoto, and T. Masumoto, J. Electro-chem. Soc. 127, 2130 (1980).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pang, S., Zhang, T., Asami, K. et al. Formation of Bulk Glassy Fe75–x–yCrxMoyC15B10 Alloys and Their Corrosion Behavior. Journal of Materials Research 17, 701–704 (2002). https://doi.org/10.1557/JMR.2002.0100

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.2002.0100