Abstract

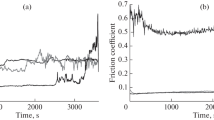

Protection of glass substrates by direct ion beam deposited diamond-like carbon (DLC) coatings was observed using a commercial pin-on-disk instrument at ambient conditions without lubrication. Ion beam sputter-deposited titanium carbide and boron carbide coatings reduced sliding friction, and provided tribological protection of silicon substrates, but the improvement factor was less than that found for DLC. Observations of unlubricated sliding of hemispherical glass pins at ambient conditions on uncoated glass and silicon substrates, and ion beam deposited coatings showed decreased wear in the order: uncoated glass > uncoated silicon > boron carbide > titanium carbide > DLC > uncoated sapphire. Failure mechanisms varied widely and are discussed. Generally, the amount of wear decreased as the sliding friction decreased, with the exception of uncoated sapphire substrates, for which the wear was low despite very high friction. There is clear evidence that DLC coatings continue to protect the underlying substrate long after the damage first penetrates through the coating. The test results correlate with field use data on commercial products which have shown that the DLC coatings provide substantial extension of the useful lifetime of glass and other substrates.

Similar content being viewed by others

References

E. Eichen and J. D. Flask, U. S. Patent No. 4,716,083, Dec. 29, 1987.

J. C. Angus, P. Koidl, and S. Domitz, in Plasma-Deposited Thin Films, edited by J. Mort and F. Jansen (CRC Press, Boca Raton, FL, 1986), p. 89.

F. M. Kimock, B. J. Knapp, and S. J. Finke, U. S. Patent No. 5,135,808, Aug. 4, 1992.

T. J. Hughes and F. M. Kimock, Soc. Vacuum Coaters 36th Ann. Tech. Conf. Proc. (1993), pp. 139–145.

F. M. Kimock and B. J. Knapp, Proc. Int. Conf. Metallurgical Coatings, San Diego, CA (1992), DLC-4.

F. M. Kimock, B. J. Knapp, and S. J. Finke, U. S. Patent No. 5,190,807, Mar. 2, 1993.

B. J. Knapp and F. M. Kimock, Soc. Vacuum Coaters 35th Ann. Tech. Conf. Proc. (1992), pp. 174–179.

F. M. Kimock, B. J. Knapp, and S. J. Finke, U. S. Patent No. 5,268,217, Dec. 7, 1993.

Patents pending.

B. J. Knapp, D. Bogy, and X. Yun, Proc. Int. Conf. Metallurgical Coatings, San Diego, CA (1993).

Patent pending.

K. Oguri and T. Arai, J. Mater. Res. 5, 2567–2571 (1990).

K. Oguri and T. Arai, Surf. Coat. Technol. 47, 710–721 (1991).

K. Kato, Wear 136, 117–133 (1990).

S. Cho, J. Kim, S. Park, and H. Moon, Wear 136, 255–261 (1990).

Y. Berthier, Wear 139, 77–92 (1990).

F. Jansen and M. A. Machonkin, Thin Solid Films 140, 227–235 (1986).

S. Aisenberg and F. M. Kimock, in Materials Science Forum, edited by J. Pouch and S. Alterovitz (Trans. Tech. Publ., Switzerland, 1990), Vols. 52 and 53, pp. 1–40.

S. Timoshenko and J. N. Goodier, in Theory of Elasticity (McGraw-Hill Book Co., New York, 1951), p. 376.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Daniels, B.K., Brown, D.W. & Kimock, F.M. Friction and wear performance of diamond-like carbon, boron carbide, and titanium carbide coatings against glass. Journal of Materials Research 12, 2485–2492 (1997). https://doi.org/10.1557/JMR.1997.0328

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1997.0328