Abstract

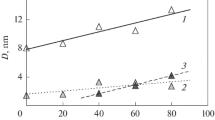

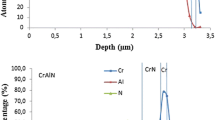

Chromium-carbon coatings have been deposited on various substrates by direct sputtering of a chromium carbide, Cr3C2, target in pure argon atmosphere. The composition of coatings determined by Rutherford backscattering spectroscopy and the deposition rate were investigated as functions of the sputtering gas pressure and self-bias voltage applied to substrates. The atom number ratio C/Cr in the coatings was equal to 0.7 regardless of the deposition conditions investigated. Oxygen and argon atoms were the major impurities incorporated in the amorphous coatings. Oxygen-free Cr-C coatings were prepared at low argon pressures or on substrates biased to a voltage in the range −100 to −320 V. The Cr-C coatings deposited on biased substrates contained less than 2 at. % of argon. The morphological features of Cr-C coatings examined by scanning electron microscopy were also dependent on the sputtering gas pressure and bias voltage of substrates. Fully dense structures were observed for coatings deposited at low argon pressures or on biased substrates. The electrical resistivity of Cr-C coatings was extremely dependent on the concentration of oxygen atoms incorporated in the coatings. Oxygen-free Cr-C coatings exhibited electrical resistivity values as low as 120 μΩ cm, i.e., less than twice the bulk resistivity of Cr3C2. The residual stresses in the coatings and microhardness of the deposited material were also investigated as functions of the deposition parameters. Tensile residual stresses were lower than 0.8 GPa, and the maximum microhardness of coatings was about 13000 MPa, i.e., similar to that of the bulk material.

Similar content being viewed by others

References

H. Dimigen and H. Hubsch, Philips Tech. Rev. 41 (6), 186 (1983/84).

H. Dimigen and H. Hubsch, U.S. Patent, 4525 417, June 25 (1985).

E. Bergmann and J. Vogel, J. Vac. Sci. Technol. A 4 (6), 2867 (1986).

Y. Pauleau and Ph. Gouy-Pailler, Mater. Lett. 13, 157 (1992).

Y. Pauleau and Ph. Gouy-Pailler, J. Mater. Res. 7, 2070 (1992).

Y. Pauleau, Ph. Gouy-Pailler, and S. Pai’dassi, Surf. Coat. Technol. 54/55, 324 (1992).

A. Aubert, J. Danroc, A. Gaucher, and J. P. Terrat, Thin Solid Films 126, 61 (1985).

S. K. Sharma and J. P. Morlevat, Thin Solid Films 156 (2), 307 (1988).

E. Bouzy, G. Le Caer, and E. Bauer-Grosse, Mater. Sci. Eng. A 133, 640 (1991).

G. Cholvy and J. L. Derep, J. Vac. Sci. Technol. A 3 (6), 2378 (1985).

G. Cholvy, J.L. Derep, and M. Gantois, Thin Solid Films 126 (1–2), 51 (1985).

V. Agarwal, V. D. Vankar, and K. L. Chopra, Thin Solid Films 169 (2), 281 (1989).

S. N. L’vov, V. F. Nemchenko, and G. V. Samsonov, Sov. Phys. Dokl. 5 (6), 1334 (1961).

B. Jonsson and S. Hogmark, Thin Solid Films 114, 257 (1984).

J. A. Thornton and D.W. Hoffman, Thin Solid Films 171, 5 (1989).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Maréchal, N., Quesnel, E. & Pauleau, Y. Deposition process and characterization of chromium-carbon coatings produced by direct sputtering of a magnetron chromium carbide target. Journal of Materials Research 9, 1820–1828 (1994). https://doi.org/10.1557/JMR.1994.1820

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/JMR.1994.1820