Abstract

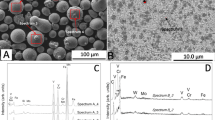

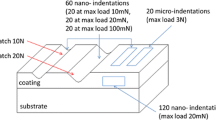

The microstructural properties of WC-Co-Cr and WC-Co coatings deposited by high-velocity oxygen fuel (HVOF) and high-velocity air fuel (HVAF) processes were investigated. The tribological behavior of the coatings was studied by means of pin-on-disk tests. Microcracking of the HVOF sprayed WC-Co coatings did not allow preparation of suitable disks for wear tests. The wear rates of the remaining coatings were determined, and wear tracks on the coatings and counterbodies were investigated by SEM. The HVAF sprayed coatings showed greater sliding-wear resistance compared to the HVOF coatings. The prime wear mechanism in the WC-Co HVAF coatings was adhesive wear. The cobalt matrix is lubricious, resulting in very low wear rates and low debris generation. The main wear mechanisms in the WC-Co-Cr coatings were adhesive and abrasive wear. Adhesive wear results in coating material dislodgments (i.e., “pullouts”) that become trapped in the contact zone and act as a third-body abrasive. Particle pullout from the coating significantly increases the wear rate of the coated specimen. The HVAF/WC-Co-Cr coatings exhibited better resistance to particle pullout, resulting in a considerably lower wear rate than the HVOF/WC-Co-Cr coatings.

Similar content being viewed by others

References

K. Akimoto, K. Akimoto, and Y. Horie, Study of HVAF WC-Cermet Coatings, Thermal Spray: Current Status and Future Trends, A. Ohmori, Ed., High Temperature Society of Japan, Osaka, Japan, 1995, p313-p316

L. Jacobs, “Influence of the HVOF Process Conditions on the Structure of WC-Co-Cr Coatings,” Master Thesis, Katholieke Universiteit Leuven, 1995 (in Dutch)

L. Jacobs, M. Hyland, and M. De Bonte, Comparative Study of WC-Cermet Coatings Sprayed via the HVOF and the HVAF Process, J. Therm. Spray Technol., Vol 7 (No. 2), 1998, p 213–219

J.M. Guilemany, L. Delaey, F.J. Sanchez, and L. Jacobs, Characterisation of WC + Co + Cr Coatings Obtained by HVOF Spraying, Metall. Ital., Vol 88 (No. 2), 1996, p 133–136

S. Economou, “Relationship between Processing, Structure and Tribological Behaviour of Carbide Reinforced Plasma Sprayed Coatings,” Ph.D. thesis, Katholieke Universiteit Leuven, Department of Metallurgy and Materials Science Engineering, Belgium, 1995

B.R. Marple, J. Voyer, and B. Arsenault, Performance of WC-Based, HVOF Processed Coatings in Sliding Wear, Thermal Spray: A United Forum for Scientific and Technological Advances, C.C. Berndt, Ed., ASM International, 1998, p 73–83

S.A. Khan and T.W. Clyne, Microstructure and Abrasion Resistance of WC-Co Coatings Produced by High Velocity Oxy-Fuel Spraying, Thermal Spray: A United Forum for Scientific and Technological Advances, C.C. Berndt, Ed., ASM International, 1998, p 681–690

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jacobs, L., Hyland, M.M. & De Bonte, M. Study of the influence of microstructural properties on the sliding-wear behavior of HVOF and HVAF sprayed WC-cermet coatings. J Therm Spray Tech 8, 125–132 (1999). https://doi.org/10.1361/105996399770350656

Issue Date:

DOI: https://doi.org/10.1361/105996399770350656