Abstract

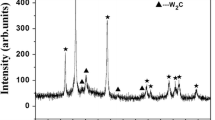

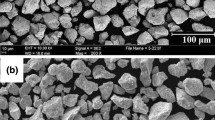

WC-12%Co-6%Cr coatings were deposited by high-velocity oxygen-fuel spraying technology (HVOF) on 42CrMo steel, and then, the sealing treatment was carried out by sol–gel aluminum phosphate inorganic sealing agent. The phases and porosity of the coatings before and after sealing were characterized by XRD and metallographic grayscale method, and high-temperature sliding wear tests were carried out at five different temperatures. The results showed that the coating/substrate bonding was mainly mechanical bonding with metallurgical bonding, and the high-temperature friction and wear mechanism of the coating was mainly contact fatigue and oxidation wear. The porosity of the coating was significantly reduced by aluminum phosphate sealing treatment, which was less than 2%, and the density was significantly improved. With the increase in wear temperature, the wear rate of the coatings increased, and the effect of phosphate sealing on reducing the wear loss was gradually weakened, and the highest service temperature was found near 450 °C.

Similar content being viewed by others

References

V. Matikainen, G. Bolelli, H. Koivuluoto, P. Sassatelli, L. Lusvarghi and P. Vuoristo, Sliding Wear Behaviour of HVOF and HVAF Sprayed Cr3C2-Based Coatings, Wear, 2017, 388–389, p 57–71.

M. Sharma, D.K. Goyal and G. Kaushal, Tribological Investigation of HVOF Sprayed Coated Turbine Steel Under Varied Operating Conditions, Mater. Today: Proc., 2020, 24, p 869–879.

P. Chhabra and M. Kaur, Elevated-Temperature Wear Study of HVOF Spray Cr3C2-NiCr-Coated Die Steels, J. Tribol., 2020, 142, p 1–33.

M.S. Lamana, A.G.M. Pukasiewicz and S. Sampath, Influence of Cobalt Content and HVOF Deposition Process on the Cavitation Erosion Resistance of WC-Co Coatings, Wear, 2018, 398–399, p 209–219.

V. Matikainen, H. Koivuluoto and P. Vuoristo, A Study of Cr3C2-Based HVOF- and HVAF-Sprayed Coatings: Abrasion, Dry Particle Erosion and Cavitation Erosion Resistance, Wear, 2020, 446–447, p 203188.

X.T. Luo, G.M. Smith, Y. Wang, E. Gildersleeve, S. Sampath and C.J. Li, Cracking Induced Tribological Behavior Changes for the HVOF WC-12Co Cermet Coatings, Ceram. Int., 2019, 45, p 4718–4728.

D.G. Bhosale, T. Ram Prabhu, W.S. Rathod, M.A. Patil and S.W. Rukhande, High Temperature Solid Particle Erosion Behaviour of SS 316L and Thermal Sprayed WC-Cr3C2-Ni Coatings, Wear, 2020, 462–463, p 203520.

T.A. Ben Mahmud, A.M. Atieh and T.I. Khan, The Wear Behavior of HVOF Sprayed Near-Nanostructured WC-17%Ni(80/20)Cr Coatings in Dry and Slurry Wear Conditions, J. Mater. Eng. Perform., 2017, 26, p 3507–3515.

L.M. Berger, Coatings by Thermal Spray, Compr. Hard Mater., 2014, 1, p 471–506.

D. Fantozzi, V. Matikainen, M. Uusitalo, H. Koivuluoto and P. Vuoristo, Chlorine Induced High-Temperature Corrosion Mechanisms in HVOF and HVAF Sprayed Cr3C2-Based Hardmetal Coatings, Corros. Sci., 2019, 160, p 108166.

G.A. Ludwig, C.F. Malfatti, R.M. Schroeder, V.Z. Ferrari and I.L. Muller, WC10Co4Cr Coatings Deposited by HVOF on Martensitic Stainless Steel for Use in Hydraulic Turbines: Resistance to Corrosion and Slurry Erosion, Surf. Coat. Technol., 2019, 377, p 124918.

W.X. Zhou, K.S. Zhou, Y.X. Li, C.M. Deng and K.L. Zeng, High Temperature Wear Performance of HVOF-Sprayed Cr3C2-WC-NiCoCrMo and Cr3C2-NiCr Hardmetal Coatings, Appl. Surf. Sci., 2017, 416, p 33–44.

T.K. Mishra, A. Kumar and S.K. Sinha, Experimental Investigation and Study of HVOF Sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr Coating on its Sliding Wear Behaviour, Int. J. Refract. Met. Hard Mater., 2021, 94, p 1054.

R. Keshavamurthy, J.M. Sudhan, A. Kumar, V. Ranjan and P. Singh, Wear Behaviour of Hard Chrome and Tungsten Carbide-HVOF Coatings, Mater. Today: Proc., 2018, 5, p 24587–24594.

Q. Wang, S.S. Luo, S.Y. Wang, H. Wang and C.S. Ramachandran, Wear, Erosion and Corrosion Resistance of HVOF-Sprayed WC and Cr3C2 Based Coatings for Electrolytic Hard Chrome Replacement, Int. J. Refract. Met. Hard Mater., 2019, 81, p 242–252.

C.D. Prasad, J. Sharnappa, M.R. Ramesh, M.S. Srinath and B.H. Channabasappa, Effect of Microwave Heating on Microstructure and Elevated Temperature Adhesive Wear Behavior of HVOF Deposited CoMoCrSi-Cr3C2 Coating, Surf. Coat. Technol., 2019, 374, p 291–304.

K. Farokhzadeh, R.M. Fillion and A. Edrisy, The Effect of Deposition Rate on Microstructural Evolution in WC-Co-Cr Coatings Deposited by High-Velocity Oxy-Fuel Thermal Spray Process, J. Mater. Eng. Perform., 2019, 28, p 1–12.

Z.Y. Zhang, D. Zhang and Y.H. Xie, Experimental Study on Water Droplet Erosion Resistance of Coatings (Ni60 and WC-17Co) Sprayed by APS and HVOF, Wear, 2019, 432–433, p 20295.

Y.K. Zhou, J.J. Kang, W. Yue, Z.Q. Fu, L.N. Zhu, D.S. She and C.B. Wang, HVOF喷涂WC系金属陶瓷涂层腐蚀磨损行为研究现状 (Research Status of Corrosion and Wear Behavior of HVOF Sprayed WC Based Cermet Coatings), Met. Heat Treatment, 2019, 44, p 211–217. (in Chinese)

A.C. Karaoglanli, Y. Ozgurluk and K.M. Doleker, Comparison of Microstructure and Oxidation Behavior of CoNiCrAlY Coatings Produced by APS SSAPS, D-gun, HVOF and CGDS Techniques, Vacuum, 2020, 180, p 109609.

A.S. Hajare and C.L. Gogte, Comparative Study of Wear Behaviour of Thermal Spray HVOF Coating on 304 SS, Mater. Today: Proc., 2018, 5, p 6924–6933.

B. Somasundaram, B.C. Navinesh and M.P. Mamatha, Wear Behavior of HVOF Sprayed WC-Co/NiCrAlYSi(35–65%) and WC-Co/NiCrAlYSi(80–20%) Coatings on Turbine SS316 Steel, Mater. Today: Proc., 2020, 20, p 103–107.

V. Testa, S. Morelli, G. Bolelli, B. Benedetti, P. Puddu, P. Sassatelli and L. Lusvarghi, Alternative Metallic Matrices for WC-Based HVOF Coatings, Surf. Coat. Technol., 2020, 402, p 126308.

J. Pulsford, F. Venturi, Z. Pala, S. Kamnis and T. Hussain, Application of HVOF WC-Co-Cr Coatings on the Internal Surface of Small Cylinders: Effect of Internal Diameter on the Wear Resistance, Wear, 2019, 432–433, p 202965.

G. Ghosh, A. Sidpara and P.P. Bandyopadhyay, Fabrication of Mechanically Durable Slippery Surface on HVOF Sprayed WC-Co Coating, Surf. Coat. Technol., 2020, 394, p 125886.

A. Mazouzi, B. Djerdjare, S. Triaa, A. Rezzoug, B. Cheniti and S.M. Aouadi, Effect of Annealing Temperature on the Microstructure Evolution, Mechanical and Wear Behavior of NiCr-WC-Co HVOF-Sprayed Coatings, J. Mater. Res., 2020, 237, p 1–10.

S. Hong, Y.P. Wu, B. Wang, J.F. Zhang, Y. Zheng and L. Qiao, The Effect of Temperature on the Dry Sliding Wear Behavior of HVOF Sprayed Nanostructured WC-CoCr Coatings, Ceram. Int., 2017, 43, p 458–462.

N. Vashishtha and S.G. Sapate, Abrasive Wear Maps for High Velocity Oxy Fuel (HVOF) sprayed WC-12Co Band Cr3C2-25NiCr Coatings, Tribol. Int., 2017, 114, p 290–305.

T.K. Mishra, A. Kumar, S.K. Sinha and S. Sharma, Investigation of Sliding Wear Behaviour of HVOF Carbide Coating, Mater. Today: Proc., 2018, 5, p 19539–19546.

C. Zheng, Y.H. Liu, J. Qin, C. Chen and R.J. Ji, Wear Behavior of HVOF Sprayed WC Coating Under Water-In-Oil Fracturing Fluid Condition, Tribol. Int., 2017, 115, p 28–34.

P.B. Mi, T. Wang and F.X. Ye, Influences of the Compositions and Mechanical Properties of HVOF Sprayed Bimodal WC-Co Coating on its High Temperature Wear Performance, Int. J. Refract. Met. Hard Mater., 2017, 69, p 158–163.

D.G. Bhosale, T.R. Prabhu and W.S. Rathod, Sliding and Erosion Wear Behaviour of Thermal Sprayed WC-Cr3C2-Ni Coatings, Surf. Coat. Technol., 2020, 400, p 126192.

Q. Liu, Y. Bai, H.D. Wang, G.Z. Ma, M. Liu, C.Y. Chu, Y.W. Sun, W. Fan, F. Ding, B. Zhao and Y.T. Wang, Microstructural Evolution of Carbides and Its Effect on Tribological Properties of SAPS or HVOF Sprayed NiCreCr3C2 Coatings, J. Alloys Compd., 2019, 803, p 730–741.

R.M. Penchal, R.A. Shakoor, P. Gururaj, M. Vyasaraj, F. Ubaid, A.M.A. Mohamed and G. Manoj, Enhanced Performance of Nano-Sized SiC Reinforced Al Metal Matrix Nanocomposites Synthesized Through Microwave Sintering and Hot Extrusion Techniques, Prog. Nat. Sci.: Mater. Int., 2017, 27, p 606–614.

M. Essam, A. Elsayed, A. Shash and M. Adly, Fabrication of Tungsten Heavy Alloy Long Rods by Warm Powder Extrusion and Vacuum Sintering, J. Mater. Res. Technol., 2019, 8, p 2209–2215.

Z.L. Xue, J.F. Liu, L.Y. Huang and Y. Han, 管道对接环焊缝裂纹的防治措施 (Preventive Measures for Crack of Girth Weld in Butt Joint of Pipeline), Oil & Gas Storage Transp., 2005, 24, p 51–52. (in Chinese)

X.Y. Zhang, F.Y. Li, Y.L. Lia, Q.L. Lu, Z. Li, H.Y. Lu, X.J. Ran and X.X. Qi, Comparison on Multi-Angle Erosion Behavior and Mechanism of Cr3C2-NiCr Coatings Sprayed by SPS and HVOF, Surf. Coat. Technol., 2020, 403, p 126366.

E.K. Hao, X.Q. Zhao, Y.L. An, W. Deng, H.D. Zhou and J.M. Chen, The Effect of Pre-Oxidation on Microstructure, Mechanical Properties and High-Temperature Tribological Behaviors of HVOF-Sprayed NiCoCrAlYTa Coating, Appl. Surf. Sci., 2019, 489, p 187–197.

Acknowledgments

The work was supported by the National Natural Science Foundation of China (50172023), the Shaanxi Industrial Science and Technology Research (2014K08-09) and the Key Research and Development Program of Shaanxi Province of China (2020GY-115).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Yw., Sun, Wc., Tian, Ss. et al. Microstructures and High-Temperature Friction and Wear Behavior of High-Velocity Oxygen-Fuel-Sprayed WC-12%Co-6%Cr Coatings before and after Sealing. J. of Materi Eng and Perform 31, 448–460 (2022). https://doi.org/10.1007/s11665-021-06167-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06167-4