Abstract

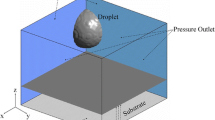

A thermal model for plasma spray deposition of ceramic materials onto metallic substrates has been developed. The enthalpy-based control volume formulation of the heat transfer processes has been used to study the temperature evolution in a two-dimensional substrate and in the coating as it is grown. In this paper, additional melting of ceramic splats after deposition is examined, with a view to predicting the retention of nanostructures in a spray consisting of agglomerated, nanometer-sized particles. Initial results for thin coatings indicate that when the mean temperature of the incoming particles is close to the fusion point of the ceramic material, the nanostructure distribution in the coating is largely determined by the composition of the spray. However, with thicker coatings, additional melting due to prolonged plasma gas heating combined with increased thermal resistance in the underlying coating leads to a loss of nanostructure.

Similar content being viewed by others

References

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, Inc., 1995

D. Poulikakos and J.M. Waldvogel, Heat Transfer and Fluid Dynamics in the Process of Spray Deposition, Advances in Heat Transfer, Vol 28, J.P. Hartnett and Y.I. Cho, Ed., Academic, Boston, 1997, p 1–74

M. Gell, The Potential for Nanostructured Materials in Gas Turbine Engines, Nanostructured Mater., Vol 6, 1995, p 997–1000

Y. Zhou, Y. Wu, and E.J. Lavernia, Process Modeling in Spray Deposition: A Review, Int. J. Non-Equilib. Proc., Vol 10, 1997, p 95–183

I. Ahmed, T.L., Bergman, and B.M. Cetegen, “A Thermal Model of the Spray Deposition of Ceramic Particles onto a Metallic Substrate,” Internal report, The University of Connecticut, 1998

G. Montavon, C.C. Berndt, C. Coddet, S. Sampath, and H. Herman, Quality Control of the Intrinsic Deposition Efficiency from the Controls of the Splat Morphologies and Deposit Microstructure, J. Therm. Spray Tech., Vol 6, 1997, p 153–166

W. Liu, G.X. Wang, and E.F. Matthys, Thermal Analysis and Measurements for a Molten Metal Drop Impacting on a Substrate: Cooling, Solidification and Heat Transfer Coefficient, Int. J. Heat Mass Transfer, Vol 38, 1995, p 1387–1395

H. Martin, Heat and Mass Transfer Between Impinging Gas Jets and Solid Surfaces, Advances in Heat Transfer, Vol 13, J.P. Hartnett and T.F. Irvine, Jr., Ed., Academic, New York, 1977, p 1–60

B.R. Hollworth and S.I. Wilson, Entrainment Effects on Impingement Heat Transfer: Part I—Measurements of Heated Jet Velocity and Temperature Distributions and Recovery Temperatures on Target Surface, ASME J. Heat Trans., Vol 106, 1984, p 797–803

B. Pateyron, M.-F. Elchinger, G. Dellue, and P. Fauchais, Thermodynamic and Transport Properties of Ar-H2 and Ar-He Plasma Gases Used for Spraying at Atmospheric Pressure. I: Properties of the Mixtures, Plasma Chem. Plasma Proc., Vol 12, 1992, p 421–448

J. Crank, Free and Moving Boundary Problems, Clarendon Press, Oxford, 1984, p 217–253

S.V. Patankar, Numerical Heat Transfer and Fluid Flow, Taylor & Francis, 1980

W. Krebs, “Multidimensional Radiative Heat Transfer in Gas Turbine Combustion Chamber Wall: Development and Verification from Inverse Calculations,” Dr.-Ing. dissertation, University of Karlsruhe, 1995 (in German)

D.P.H. Hasselman, L.F. Johnson, L.D. Bensten, R. Syed, H.L. Lee, and M.V. Swain, Thermal Diffusivity and Conductivity of Dense Polycrystalline ZrO2 Ceramics: A Survey, Am. Ceram. Soc. Bull., Vol 66, 1987, p 799–806

F.P. Incropera and D.P. DeWitt, Fundamentals of Heat and Mass Transfer, 4th ed., John Wiley & Sons, 1996, Appendix A

B.M. Cetegen and W. Yu, In-Situ Particle Temperature, Velocity and Size Measurements in DC Arc Plasma Thermal Sprays, J. Thermal Spray Tech., Vol 8, 1999, p 57–67

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ahmed, I., Bergman, T.L. Thermal modeling of plasma spray deposition of nanostructured ceramics. J Therm Spray Tech 8, 315–322 (1999). https://doi.org/10.1361/105996399770350539

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996399770350539