Abstract

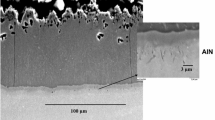

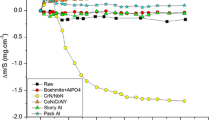

The useful life of superheaters and reheaters of power stations which use heavy fuel oil is shortened and their continuous service is inhibited by corrosion (fireside) and creep-type problems. The increase of corrosion attack on boilers is caused by the presence of fuel ash deposits containing mainly vanadium, sodium, and sulfur which form low-melting-point compounds. The tubes are exposed to the action of high stresses and high temperatures, producing the so-called “creep damage.” In this work, two kinds of results are reported: lab and field studies using a 2.25Cr-1Mo steel. The laboratory work was in turn divided into two parts. In the first, the steel was exposed to the action of natural ash deposits in oxidant atmospheres at 600 ° for 24 h. In the second part, tensile specimens were creep tested in Na2SO4, V2O5, and their mixture over a temperature range of 580 to 620 °. In the field work, components of a power station were coated with different types of nickel-and iron-base coatings containing chromium, Fe-Cr, and Fe-Si using the powder flame spraying technique. After testing, the coated tubes were analyzed using electron microscopy. The results showed that all the coating systems had good corrosion resistance, especially those containing silicon or chromium.

Similar content being viewed by others

References

Y. Harada, High Temperature Corrosion in Heavy Oil Firing Boilers,Corrosion, 1972, p 841–845

H.H. Reichel, Fireside Corrosion in German Fossil-Fuel Fired Power Plants: Appearance, Mechanism and Causes,Werkst. Korros., Vol 39 (No. 2), 1988, p 54–63

“Residual Fuel Oil User’s Guide Book,” EPRI Report AP-5826, Chapter 5, Emissions, Vol 2, August, 1988

L.D. Paul and R.R. Seeley, Oil-Ash Corrosion—A Review of Utilitily Boiler Experience,Corrosion, Vol 47 (No. 2), 1991, p 152–159

D.B. Meadowcroft, High Temperature Corrosion of Alloys and Coatings in Oil- and Coal-Fired Boilers,Mat. Sci. Eng., Vol 88, 1987, p 313–320

A. Martínez-Villafañe, G. Arroyo-Figueroa, and A. Peraza,Adv. Chem. Eng., Vol 2, 1989, p 799

A. Peraza, A. Martínez-Villafañe, M. Ley-Koo, S. D’Granda, J. Uruchurtu and E. García, EPRI Report GS-6459S, 1989

G. Arroyo-Figueroa, B.Sc. Thesis, Tecnológico de Celaya, 1988

R. Sivakumar and B.L. Mordiek,Surf. Coat. Technol., Vol 37 (No. 2), 1989, p 139

F.H. Stott,Mater. Sci. Technol., Vol 5, 1989, p 734

J.G. Gonzalez-Rodriguez, J. Porcayo-Calderon, and A. Martínez-Villafane, A Novel Technique to Control High Temperature Materials Degradation in Fossil Plants, paper presented at Corrosion 95 (Houston, TX), National Association of Corrosion Engineers, 1995

S. Ahila, S. Ramakrishna, and V.M. Radhakrishnan,Indian Inst. Met., 1993, p 215

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Martínez-Villafañe, A., Almeraya-Calderón, M.F., Gaona-Tiburcio, C. et al. High-temperature degradation and protection of ferritic and austenitic steels in steam generators. J. of Materi Eng and Perform 7, 108–113 (1998). https://doi.org/10.1361/105994998770348124

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105994998770348124