Abstract

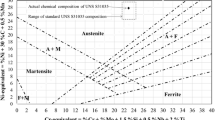

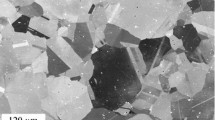

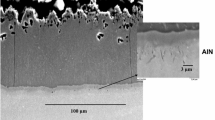

UNS S31035 austenitic stainless steel grade is a newly developed advanced heat resistant material for use in coal fired boilers at metal temperatures up to 700 °C. This new grade that has recently got two AMSE code cases shows good resistance to steam oxidation and flue gas corrosion and high creep rupture strength. This paper will mainly focus on the characterization of long term structure stability and performances such as the creep behaviors at different temperatures for up to 86,000 h at high temperatures. The creep damage mechanisms were studied using electron transmission microscopy, electron backscatter diffraction, and electron channeling contrast image analysis. The results show that the creep strength is related to the intragranular nano particles that act as obstacles for dislocation movements. Plastic deformation and transgranular fracture is the main creep fracture mechanism in the creep test samples of UNS S31035. The material has good creep ductility by formation of twins during the creep test. This material has been installed and tested in several European power plants, and has shown good performance. The material is an excellent alternative for superheaters and reheaters in future high-efficient coal fired boilers with design material temperatures up to 700 °C, instead of more costly nickel based alloy.

Zusammenfassung

UNS S31035, ein hitzebeständiger austenitischer nichtrostender Stahl, setzt neue Maßstäbe für den Einsatz in mit kohlebefeuerten Dampferzeugern für Materialtemperaturen bis 700 °C. Der neue Werkstoff, welcher für zwei ASME Code Case zugelassen ist, zeichnet sich durch gute Beständigkeit gegen Dampf- und Rauchgaskorrosion sowie eine hohe Zeitstandfestigkeit aus. Diese Veröffentlichung legt den Schwerpunkt auf das Langzeitverhalten (bis 68000 h), charakterisiert durch Strukturstabilität und das Kriechverhalten bei unterschiedlichen Temperaturen. Die Kriechversagensmechanismen wurden mittels Transmission Electron Microscope (TEM), Electron Back Scatter Diffraction (EBSD) und Electron Channelling Contrast Image (ECCI) untersucht. Die Ergebnisse zeigen einen Zusammenhang zwischen Zeitstandfestigkeit und intergranularen Ausscheidungen sowie die Behinderung von Versetzungsbewegungen durch Nanoteilchen. Plastische Verformung und transkristalline Brüche sind die Hauptausfallmechanismen der untersuchten Zeitstandproben aus UNS S31035. Der Werkstoff weist eine gute Kriechduktilität durch Zwillingsbildung während des Zeitstandversuchs auf. UNS S31035 wurde in mehreren Europäischen Kohlekraftwerken installiert und getestet und zeigte eine gute Performance. UNS S3105 ist eine hervorragende Alternative für Überhitzer und Zwischenüberhitzer in hocheffizienten Dampferzeugern für Design-Materialtemperaturen bis zu 700 °C, als Alternative zu heute verwendeten Nickelbasislegierungen.

Similar content being viewed by others

Literatur

IEA, 2009 energy statistics, http://www.iea.org/stats (25.02.2010)

Blum, R.; Vanstone, R.W.; Messelier-Gouze, C.: Materials Development for Boilers and Steam Turbines Operating at 700 °C, Proc. 4th Int. Conf. on Adv. in Mater. Technol. for Fossil Power Plant, 2004, pp 116–123

Rautio, R.; Bruce, S.: Sandvik Sanicro 25, a new material for ultra supercritical coal fired boilers, Proc. 4th Inter Conf. on Adv. in Mater. Technol. for fossil power plants, 2004, pp 274–281

Chai, G.; Nilsson, J.O.; Boström, M.; Högberg, J.; Forsberg, U.: Advanced Heat Resistant Austenitic Stainless Steels, Proc. of ICAS 2010, 2010, pp 56–63

Chai, G.; Boström, M.; Kjellström, P.; Forsberg, U.: Creep and LCF Behaviors of Newly Developed Advanced Heat Resistant Austenitic Stainless Steel for A-USC, Procedia Engineering, 55 (2013), pp 232–239

Kim, Y. U.; Kwun, S. I.; Shim, J. H.; Park, D. B.; YCho, W.; Chung, Y. H.; Jung, W. S.: The Effect of Cooling Conditions after Solution Treatment on the Creep Rupture Strength of Sanicro 25, www.nims.go.jp/hrdg/USC/Proceeding/Proceeding033Jung.pdf, 3rd Symposium on Heat Resistant Steels and Alloys for High Efficiency USC Power Plants 2009

Latha, S.; Mathew, M. D.; Parameswaran, P.; Sankara, K. B.; Mannan, S. L.: Thermal creep properties of alloy D9 stainless steel and 316 stainless steel fuel clad tubes, Int. J. Pre. Vess. Pip., 85 (2008), pp 866–878

Sourmail, T.: Precipitation in creep resistant austenitic stainless steels, Mater. Sci. Technol., 17 (2001), pp 1–14

Tohyama, A.; Minami, Y.: Development of the High Temperature Materials for Ultra Super Critical Boilers, in: Viswanathan, R.; Nutting, J. (ed.): Advanced Heat Resistant Steels for Power Generation, London, IoM Communications Ltd, (1999), pp 494–505

Laha, A. K.; Kyonob, J.; Shinya, N.: An advanced creep cavitation resistance Cu-containing 18Cr–12Ni–Nb austenitic stainless steel, Scripta Materialia, 56 (2007), pp 915–918

Davison, R. M.; Laurin, T. R.; Redmond, J. D.; Watanabe, H.; Semchyshen, M.: A review of worldwide developments in stainless steels, Materials & Design, 7 (1986), No. 3, pp 111–119

Sandström, R.: A procedure for extended extrapolation of creep rupture data, Journal of Testing and Evaluation, 31 (2003), pp 58–66

Sandström, R.; Lindé, L.: Precision in the extrapolation of creep rupture data, Journal of Testing and Evaluation, 27 (1999), No. 3, pp 203–210

Acknowledgements

This paper is published by permission of Sandvik Materials Technology. ECCI work by Mr Jerry Lindqvist and TEM investigation by Dr Magnus Boström are greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chai, G., Hernblom, J., Peltola, T. et al. Creep Behavior in A Newly Developed Heat Resistant Austenitic Stainless Steel. Berg Huettenmaenn Monatsh 160, 400–405 (2015). https://doi.org/10.1007/s00501-015-0404-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00501-015-0404-z