Abstract

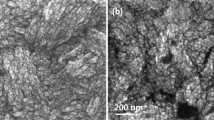

Chemical vapor deposited diamond films have many industrial applications but are assuming increasing importance in the area of microengineering, most notably in the development of diamond coated microgrinding tools. For these applications the control of structure and morphology is of critical importance. The crystallite size, orientation, surface roughness, and the degree of sp 3 character have a profound effect on the tribological properties of the films deposited. In this article, we present experimental results on the effects of nitrogen doping on the surface morphology, crystallite size, and wear of microgrinding tools. The sp 3 character optimizes at 200 ppm nitrogen, and above this value the surface becomes much smoother and crystal sizes decrease considerably. Fracture-induced wear of the diamond grain is the most important mechanism of material removal from a microgrinding tool during the grinding process. Fracture occurs as a consequence of tensile stresses induced into diamond grains by grinding forces to which they are subjected. The relationship between the wear of diamond coated grinding tools, component grinding forces, and induced stresses in the model diamond grains is described in detail. A significant correlation was found between the maximum value of tensile stress induced in the diamond grain and the appropriate wheel-wear parameter (grinding ratio). It was concluded that the magnitude of tensile stresses induced in the diamond grain by grinding forces at the rake face is the best indicator of tool wear during the grinding process.

Similar content being viewed by others

References

Q.H. Fan, E. Periera, and J. Gracio, Time Modulated CVD Diamond Processing of Diamond, J. Mater. Res., 1998, Vol 13 (No. 10), p 2787–2794

P. May, C.A. Rego, R.M. Thomas, M.N.R. Ashfold, K.N. Rosser, and N.M. Everitt, CVD Diamond Wires and Tubes, Diamond Relat. Mater., Vol 3, 1994, p 810–813

L. Kostadinov, D. Dobrev, K. Okano, T. Kurosu, and M. Iida, Nucleation and Growth of Diamond from the Vapor Phase, Diamond Relat. Mater., Vol 1 1992, p 157–160

N. Ali, W. Ahmed, I.U. Hassan, and C.A. Rego, Surface Engineering of Diamond Coated Tools, Surf. Eng., Vol 14 (No. 4), 1998, p 292

R. Beckmann, W. Kulisch, H.J. Frenck, and R. Kassing, Influence of Gas Phase Parameters on Diamond Kinematics of Thin Diamond Films Deposited by MWCVD and HFCVD Techniques, Diamond Relat. Mater., Vol 1, 1992, p 164–167

S.I. Ojika, S. Yamoshita, and T. Ishikura, Diamond Growth on Copper Substrate, Jpn. J. Appl. Phys., Vol 32 (No. 2), 1998, p L1681-L1683

W. Muller-Serbert, E. Worner, F. Fuchs, C. Wild, and P. Koidl, Nitrogen Induced Increase in Growth Rate in CVD Diamond, Appl. Phys. Lett., Vol 68 (No. 6), 1996, p 759–760

B. Bohr, R. Haubner, and B. Lux B, Influence of Nitrogen Additions on HFCVD Diamond, Appl. Phys. Lett., Vol 68 (No 8), 1996, p 1075–1077

W.A. Yarbrough and R. Messier R., Diamond Deposition to Silicon, Science, Vol 247, 1988, p 688

S.M. Kanetkar, G. Metera, X. Chen, S. Pramanick, P. Tiwari, J. Narayan, G. Pfeiffer, and M. Paesler, Growth of Diamond on Silicon Substrates, J. Electron. Mater., Vol 20, 1991, p 4–11

S.D. Wolter, B.R. Stoner, J.T. Glass, P.J. Ellis, D.S. Jenkins, and P. Southworth, Textured Growth of Diamond on Silicon via in situ Carburization and Bias Enhanced Nucleation, Appl. Phys. Lett., Vol 62, 1993, p 1215–1217

X. Jiang, C.P. Klages, R. Zachia, M. Hartureg, and H.J. Fuser, Epitaxial Diamond Films on (001) Silicon Substrates, Appl. Phys. Lett., Vol 62, 1993, p 3438–3440

F. Stubhan, M. Ferguson, H.J. Fusser, and R.J. Behom, Heteroepitaxial Nucleation of Diamond on Si (001) in HFCVD, Appl. Phys. Lett., Vol 66, 1995, p 1900–1902

X. Li, Y. Hayashi, and S. Nishino, Analysis of Oriented Diamond Nucleation Processes on Silicon Substrates by HFCVD, Jpn. J. Phys., Vol 36, 1997, p 5197–5201

R. Locher, C. Wild, N. Herres, D. Behr, and P. Koidl, Nitrogen Stabilized 〈100〉 texture in CVD Diamond Films, Appl. Phys. Lett., Vol 65, 1994, p 34–36

S. Jin and T.D. Moustakas, Effect of Nitrogen on the Growth of Diamond Films, Appl. Phys. Lett., Vol 65, 1994, p 403–405

T.H. Borst, P.C. Munzinger, and O. Weiss, Characterization of Undoped and Doped Homoepitaxial Diamond Layers Produced by Microwave Plasma CVD, Diamond Relat. Mater., Vol 3, 1994, p 515–519

S. Koizumi, M. Kamo, Y. Sato, S. Mita, A. Sauabe, and C. Reznik, Growth and Characterization of Phosphorous Doped N-Type Diamond Films, Diamond Relat. Mater., Vol 7, 1998, p 540–544

L.P. Tarasov, Grindability of Tool Steels, American Society of Metals, Vol 43, 1951, p 1144–1151

H.K. Tonshoff and T. Grabner, Cylindrical and Profile Grinding with Boron Nitride Wheels, Proceedings of the 5th International Conference on Production Engineering, Japanese Society of Precision Engineers, Tokyo, Japan 1984, p 326

S. Malkin and N.H. Cook, The Wear of Crinding Wheels—Part 1: Attritious Wear, Trans. A.S.M.E. J. Eng. Ind., Vol 93, 1971, p 1120–1128

M.J. Jackson, Vitrification Heat Treatment during the Manufacture of Corundum Grinding Wheels, J. Mfg. Proc., Vol 3, 2001, p 17–28

S.P. Timoshenko and J.N. Goodier, Theory of Elasticity, 3rd ed., International Student Edition, McGraw-Hill Kogakusha, Tokyo, Japan 1970, p 109–113, 139–144

A.G. King and W.M. Wheildon, Ceramics in Machining Processes (Academic Press, New York, 1966)

A.A. Griffith, The Phenomena of Rupture and Flow in Solids, Philos. Trans. R. Soc. London, Vol A221, 1921, p 163–198

T.N. Loladze, Requirement of Tool Materials, Proceedings of the 8th International Machine Tool Design and Research Conference, Koenigsberger, Ed., Pergamon Press, 1967, p 821–842

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jackson, M.J., Ahmed, W. Characterization of N-doped polycrystalline diamond films deposited on microgrinding tools. J. of Materi Eng and Perform 14, 654–665 (2005). https://doi.org/10.1361/105994905X64585

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994905X64585