Abstract

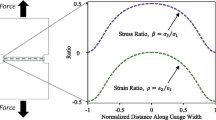

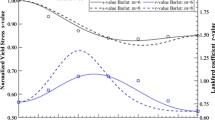

Accurate assessment of plastic anisotropy is essential to many material models used in computer-aided sheet metal forming simulations. In this analysis, the influence of discontinuous yielding (yield point elongation or YPE) on normal anisotropy (R-value) measurements was examined. A laboratory-annealed, non temper-rolled, aluminum-killed drawing quality (AKDQ) steel was considered. It was found that discontinuous yielding significantly influences R-value calculations by imposing an effective offset to the width strain measurement during a sheet tensile test if the R-value is defined in terms of total strains (R=ɛW/ɛT). The effect may be positive or negative and shows considerable variability between tests. For a more accurate and consistent representation of normal anisotropy, the incremental R-value (R’=dɛW/dɛT) should be used in cases of significant YPE. A procedure has been developed to account for the low-strain effects of discontinuous yielding on plastic anisotropy measurements, where the R’-value is determined in a region of stable, uniform deformation on the stress/strain curve. For adequately temper rolled materials (with minimal YPE) and for inherently YPE-free materials, the R-value may be determined in the conventional way.

Similar content being viewed by others

References

R.L. Whitely, The Importance of Directionality in Drawing Quality Sheet Steel, Trans. Am. Soc. Met., Vol 52, 1960, p 154–169

R. Hill, A Theory of the Yielding and Plastic Flow of Anisotropic Metals, Proc. R. Soc. London, Vol A193, 1948, p 281–297

F. Barlat, Y. Maeda, K. Chung, M. Yanagawa, J.C. Brem, Y. Hayashida, D.J. Lege, K. Matsui, S.J. Murtha, S. Hattori, R.C. Becker, and S. Makosey, Yield Function Development for Aluminum Alloy Sheets, J. Mech. Phys. Solids, Vol 45, 1997, p 1727–1763

P.D. Wu, M. Jain, J. Savoie, S.R. MacEwan, P. Tugcu, and K.W. Neale, Evaluation of Anisotropic Yield Functions for Aluminum Sheets, Int. J. Plasticity, Vol 19, 2003, p 121–138

G.E. Dieter, Mechanical Metallurgy, 3rd ed., McGraw-Hill, New York, 1986

W.F. Hosford and R.M. Caddell, Metal Forming—Mechanics and Metallurgy, Prentice-Hall, Englewood Cliffs, NJ, 1983

S. Kalpakjian, Manufacturing Processes for Engineering Materials, 2nd ed., Addison-Wesley, 1992

S.L. Semiatin and J.J. Jonas, Formability & Workability of Metals—Plastic Instability & Flow Localization, ASM, 1984

M-G. Lee, D. Kim, C. Kim, M.L. Wenner, R.H. Wagoner, and K. Chung, Spring-Back Evaluation of Automotive Sheets Based on Isotropic-Kinematic Hardening Laws and Non-Quadratic Anisotropic Yield Functions, Part II: Characterization of Material Properties, Int. J. Plasticity, Vol 21, 2005, p 883–914

“Standard Test Method for Plastic Strain Ratio r for Sheet Metal,” E 517 – 98, ASTM, 1998

P.R. Mould and T.E. Johnson, Rapid Assessment of Drawability of Cold-Rolled Low-C Steel Sheets, Sheet Metal Ind., Vol 50 (No. 6), 1973, p 328–330, 332, 348

G.T. Van Rooyen, The Stress and Strain Distribution in a Propagating Lüders Front Accompanying the Yield-point Phenomenon in Iron, Mat. Sci. Eng., Vol 3, 1969, p 105–117

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hance, B.M. Influence of discontinuous yielding on normal anisotropy (R-value) measurements. J. of Materi Eng and Perform 14, 616–622 (2005). https://doi.org/10.1361/105994905X64576

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994905X64576