Abstract

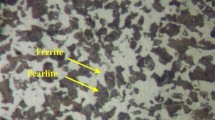

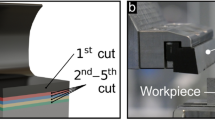

In recent years, the finite element method (FEM) has become the main tool for simulating the metal cutting process because research based on trial and error is time consuming and requires high investment. Early studies were done by different investigators. In this research AISI 52100, hardened steel (62 HRC) was selected for an orthogonal machining process as well as metal cutting simulation using the software DEFORM-2D. This software is based on a forging process and has been adapted to an orthogonal machining process. The results of simulated cutting forces were compared with experimental cutting force data to validate the orthogonal cut simulation. Also, the surface roughness was measured, and the influence of the stress, strain, and temperature on the surface roughness was studied.

Similar content being viewed by others

References

M.E. Merchant, Mechanics of the Metal Cutting Process, J. Appl. Physics, Vol 16 (No. 6), 1945, p 318–324

E.H. Lee and B.W. Schaffer, Theory of Plasticity Applied problems of Machining, ASME J. Appl. Mech., Vol 18 (No. 4), 1951, p 104–113

A.O. Tay, M.G. Stevenson, and G. De Vahl Davis, Using the Finite Element Method to Determine Temperature Distributions in Orthogonal Machining, Proc Inst. Mech. Eng., Vol 188, 1974, p 627–637

W.F. Hasting, P. Mathew, and P.L.B. Oxley, A Machning Theory for Predicting Chip Geometry, Cutting Forces, Etc., From Work Material Properties and Cutting Conditions, Proc. Royal Soc. (London), Vol A371, 1980, p 569–587

D. Lee, The Nature of Chip Formation in Orthogonal Machining, J. Eng. Mater. Technol., Vol 106, 1984, p 9–15

J.S. Strenkowski and J.T. Carrol, A Finite Element Model of Orthogonal Metal Cutting, J. Eng. Industry, Vol 107, 1985, p 349–354

T.H.C. Childs and K. Maekawa, Computer-Aided Simulation and Experimental Studies of Chip Flow and Tool Wear in the Turning of Low Alloy Steels by Cemented Carbide Tools, Wear, Vol 139, 1990, p 235–250

K. Komvopoulos and S.A. Erpenbeck, Finite Element Modeling of Orthogonal Metal Cutting, J. Eng. Industry, Vol 113, 1991, p 253–267

B. Zhang and A. Bagchi, Finite Element Simulation of Chip Formation and Comparison with Machining Experiment, Computational Methods in Materials Processing, PED-Vol. 61, ASME, 1992, p 61–74

G.S. Sekhon and J.L. Chenot, Numerical Simulation of Continuous Chip Formation During Non-Steady Orthogonal Cutting, Eng. Comp., Vol 10, 1993, p 31–48

E.G. Ng, D.K. Aspinwall, D. Brazil, and J. Monagham, Modelling of Temperature and Forces when Orthogonally Machining Hardened Steel, Int. J. Mach. Tools Manuf., Vol 39, 1999, p 885–903

S. Chandrakanth and X. Deng, Finite Element Analysis of the Orthogonal Metal Cutting Process, J. Mater. Proc. Technol., Vol 105, 2000, p 95–109

A.G. Mamalis, M. Horvath, A.S. Branis, and D.E. Manolakos, Finite Element Simulation of chip Formation in Orthogonal Metal Cutting, J. Mater. Proc. Technol., Vol 110, 2001, p 19–27

M.H. Dirikolu, T.H.C. Childs, and K. Maekawa, Finite Element Simulation of Chip Flow in Metal Machining, Inter. J. Mech. Sci., Vol 43, 2001, p 2699–2713

A. Ramesh, “Prediction of Process-Induced Microstructural changes and Residual Stresses in Orthogonal Hard Machining,” Ph.D. Dissertation, Georgia Institute of Technology, Atlanta, GA, June 2002

G. Toledo, “High Temperature Compression Testing of Hardened Steels for Plasticity Behavior Modeling,” MS Thesis, Georgia Institute of Technology, Atlanta, GA, 2002

H.T. Young and P. Mathew, Allowing for Nose Radius Effects in Predicting the Chip Flow and Cutting Forces in Bar Turning, Proc. Inst. Mech. Eng., Vol 201 (No. C3), 1987, p 213–226

Y.S. Tarng and T.S. Hwang, An Investigation of the Specific Cutting Force and its Direction Factors in Turning, Comp. Struct., Vol 53 (No. 4), 1994, p 937–945

Z. Cassier, P. Munoz-Escalona, and R. Sanchez, Influence of the Cutting Parameters on the Cutting Forces of Carbon Steel, ASME, 2002, p 117–121

J. Datsko, Materials Selection for Design and Manufacturing: Theory and Practice, Marcel Dekker, Inc., New York, 1997, p 177–280 and 307–324

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Muñoz-Escalona, P., Melkote, S. & Liu, K. Influence of the stress, strain, and temperature on the surface roughness of an AlSl 52100 steel due to an orthogonal cut. J. of Materi Eng and Perform 14, 582–590 (2005). https://doi.org/10.1361/105994905X64521

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994905X64521