Abstract

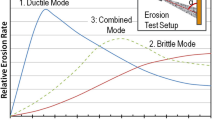

Various methods of thermal shock testing are used by aircraft and industrial gas turbine engine (IGT) manufacturers to characterize new thermal barrier coating systems in the development stage as well as for quality control. The cyclic furnace oxidation test (FCT), widely used in aircraft applications, stresses the ceramic/bondcoat interface, predominantly through thermally grown oxide (TGO) growth stress. The jet engine thermal shock (JETS) test, derived from a burner rig test, creates a large thermal gradient across the thermal barrier coating (TBC), as well as thermomechanical stress at the interface. For IGT applications with long high-temperature exposure times, a combination of isothermal preoxidation and thermal shock testing in a fluidized bed reactor may better represent the actual engine conditions while both types of stress are present. A comparative evaluation of FCT, JETS, and a combined isothermal oxidation and fluidized bed thermal shock test has been conducted for selected ceramic/bondcoat systems. The results and the failure mechanisms as they relate to the TBC system are discussed. A recommendation on the test method of choice providing best discrimination between the thermal shock resistance of the ceramic layer, the ceramic/bondcoat interface, and even substrate related effects, is given.

Similar content being viewed by others

References

A. Maricocchi, A. Barz, and D. Wortman: “PVC TBC. Experience on GE Aircraft Engines,” in Proceedings Thermal Barrier Coating Workshop, NASA Lewis Research Center, Cleveland, Ohio, March 27–29, 1995, p. 85.

T.A. Taylor: “Thermal Barrier Coating for Substrates and Process for Producing It,” U.S. Patent No. 5,073,433 and 4,743,013, December 17, 1991.

T.A. Taylor and R.E. Taylor: “Testing of Stability and Thermal Properties of Thermal Barrier Coatings,” ASM Handbook Volume 5, Surface Engineering, ASM International, Materials Park, OH, 1994, pp. 654–59.

J. Foster: “Protective Coating,” U.S. Patent Nos. 5,558,758, 5,824,205, and 5,839,829, 20 October 1998.

A. Kahn, T. Duda, A. Taylor, P. Moore, P. Rutter, and J. Foster: “Oxidation Behavior of Electroplated MCrAlY Coatings,” Proc. Thermal Spray Conference 2003, ASM International, Materials Park, OH, 2003, pp. 741–44.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bolcavage, A., Feuerstein, A., Foster, J. et al. Thermal shock testing of thermal barrier coating/bondcoat systems. J. of Materi Eng and Perform 13, 389–397 (2004). https://doi.org/10.1361/10599490419883

Received:

Issue Date:

DOI: https://doi.org/10.1361/10599490419883