Abstract

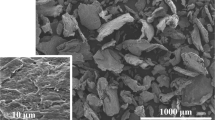

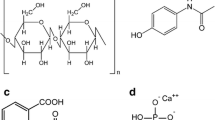

Bacterial cellulose (BC) is an interesting material for drug delivery applications due to its high purity. This study aimed to compare the properties of tablets prepared by the wet granulation method using bacterial cellulose prepared by different methods as a diluent, using acetaminophen as a model drug. BC used as diluents were prepared using two different methods: freeze-drying (BC-FD) and phase-inversion (BC-PI), and their characteristics were analyzed and compared with that of commercial microcrystalline cellulose PH 101 (Comprecel® M101). Acetaminophen tablets were prepared by wet granulation using BC-FD, BC-PI, or Comprecel® M101 as diluents, and their tablet properties were examined. The result showed that the morphology, polymorph, and crystallinity of BC-PI and Comprecel® M101 were similar but they were different compared with that of BC-FD. Tablets could be successfully formed using BC-PI and Comprecel® M101 as diluents without any physical defects but the tablet prepared using BC-FD as diluent appeared chipped edge. The characteristics (thickness, weight variation, hardness, friability, disintegration, drug content, and dissolution) of the tablets prepared using BC-PI diluent were also similar to those prepared using Comprecel® M101 diluent, but those of BC-FD diluent were inferior. This indicates that BC prepared in BC-PI can potentially be used as a diluent for tablets prepared by wet granulation.

Graphical Abstract

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

Trache D, Hussin MH, Chuin CTH, Sabar S, Fazita MN, Taiwo OF, et al. Microcrystalline cellulose: Isolation, characterization and bio-composites application—A review. Int J Biol Macromol. 2016;93:789–804. https://doi.org/10.1016/j.ijbiomac.2016.09.056.

Hare C, Bonakdar T, Ghadiri M, Strong J. Impact breakage of pharmaceutical tablets. Int J Pharm. 2018;536(1):370–6. https://doi.org/10.1016/j.ijpharm.2017.11.066.

van der Merwe J, Steenekamp J, Steyn D, Hamman J. The role of functional excipients in solid oral dosage forms to overcome poor drug dissolution and bioavailability. Pharmaceutics. 2020;12(5):393. https://doi.org/10.3390/pharmaceutics12050393.

Vaidya MP, Avachat AM. Investigation of the impact of insoluble diluents on the compression and release properties of matrix based sustained release tablets. Powder Technol. 2011;214(3):375–81. https://doi.org/10.1016/j.powtec.2011.08.035.

Kulkarni P, Dixit SA, Singh U. Evaluation of bacterial cellulose produced form Acetobacter xylinum as pharmaceutical excipient. Am J Drug Discov Dev. 2012;2:72–86. https://doi.org/10.3923/ajdd.2012.72.86.

Tobyn MJ, McCarthy GP, Staniforth JN, Edge S. Physicochemical comparison between microcrystalline cellulose and silicified microcrystalline cellulose. Int J Pharm. 1998;169(2):183–94. https://doi.org/10.1016/S0378-5173(98)00127-6.

Rojas J, López A, Gamboa Y, González C, Montoya F. Assessment of processing and polymorphic form effect on the powder and tableting properties of microcrystalline celluloses I and II. Chem Pharm Bull. 2011;59(5):603–7. https://doi.org/10.1248/cpb.59.603.

Zhao H, Shi C, Zhao L, Wang Y, Shen L. Influences of different microcrystalline cellulose (MCC) grades on tablet quality and compression behavior of MCC-lactose binary mixtures. J Drug Deliv Sci Technol. 2022;77:103893. https://doi.org/10.1016/j.jddst.2022.103893.

Lin S-P, Loira Calvar I, Catchmark JM, Liu J-R, Demirci A, Cheng K-C. Biosynthesis, production and applications of bacterial cellulose. Cellulose. 2013;20:2191–219. https://doi.org/10.1007/s10570-013-9994-3.

Belali NG, Chaerunisaa AY, Rusdiana T. Isolation and characterization of microcrystalline cellulose derived from plants as excipient in tablet: A review. Indones J Pharm. 2019;1:23–9. https://doi.org/10.24198/idjp.v1i2.21515.

Lupidi G, Pastore G, Marcantoni E, Gabrielli S. Recent developments in chemical derivatization of microcrystalline cellulose (MCC): Pre-treatments, functionalization, and applications. Molecules. 2023;28:2009. https://doi.org/10.3390/molecules28052009.

Viera-Herrera C, Santamaría-Aguirre J, Vizuete K, Debut A, Whitehead DC, Alexis F. Microcrystalline cellulose extracted from native plants as an excipient for solid dosage formulations in drug delivery. Nanomaterials. 2020;10(5):975. https://doi.org/10.3390/nano10050975.

Wohlert M, Benselfelt T, Wågberg L, Furó I, Berglund LA, Wohlert J. Cellulose and the role of hydrogen bonds: not in charge of everything. Cellulose. 2022;29:1–23. https://doi.org/10.1007/s10570-021-04325-4.

Chawla PR, Bajaj IB, Survase SA, Singhal RS. Microbial cellulose: fermentative production and applications. Food Technol Biotechnol. 2009;47(2):107–24.

Kurosumi A, Sasaki C, Yamashita Y, Nakamura Y. Utilization of various fruit juices as carbon source for production of bacterial cellulose by Acetobacter xylinum NBRC 13693. Carbohydr Polym. 2009;76:333–5. https://doi.org/10.1016/j.carbpol.2008.11.009.

Jantarat C, Muenraya P, Srivaro S, Nawakitrangsan A, Promsornpason K. Comparison of drug release behavior of bacterial cellulose loaded with ibuprofen and propranolol hydrochloride. RSC Adv. 2021;11:37354–65. https://doi.org/10.1039/D1RA07761A.

Czaja W, Krystynowicz A, Bielecki S, Brown RM Jr. Microbial cellulose—the natural power to heal wounds. Biomaterials. 2006;27:145–51. https://doi.org/10.1016/j.biomaterials.2005.07.035.

Almeida I, Pereira T, Silva N, Gomes F, Silvestre A, Freire C, et al. Bacterial cellulose membranes as drug delivery systems: An in vivo skin compatibility study. Eur J Pharm Biopharm. 2014;86:332–6. https://doi.org/10.1016/j.ejpb.2013.08.008.

Ullah H, Wahid F, Santos HA, Khan T. Advances in biomedical and pharmaceutical applications of functional bacterial cellulose-based nanocomposites. Carbohydr Polym. 2016;150:330–52. https://doi.org/10.1016/j.carbpol.2016.05.029.

Sahudin S, Hussain M, Abd Rahman S, Hamdan MAS, Abd Rahim MR. The use of nata de coco derived bacterial cellulose as a potential excipient for directly compressed tablets. Int Pharm Acta. 2020;3(1):3e2-1-5. https://doi.org/10.22037/ipa.v3i1.29058.

Zhang CJ, Wang L, Zhao JC, Zhu P. Effect of drying methods on structure and mechanical properties of bacterial cellulose films. Adv Mat Res. 2011;239:2667–70. https://doi.org/10.4028/www.scientific.net/AMR.239-242.2667.

Lee K-Y, Bismarck A. Susceptibility of never-dried and freeze-dried bacterial cellulose towards esterification with organic acid. Cellulose. 2012;19:891–900. https://doi.org/10.1007/s10570-012-9680-x.

Shanmugam S. Granulation techniques and technologies: recent progresses. Bioimpacts. 2015;5:55–63. https://doi.org/10.15171/bi.2015.04.

Kushner J 4th, Langdon BA, Hiller JI, Carlson GT. Examining the impact of excipient material property variation on drug product quality attributes: a quality-by-design study for a roller compacted, immediate release tablet. J Pharm Sci. 2011;100(6):2222–39. https://doi.org/10.1002/jps.22455.

Jantarat C, Attakitmongkol K, Nichsapa S, Sirathanarun P, Srivaro S. Molecularly imprinted bacterial cellulose for sustained-release delivery of quercetin. J Biomater Sci Polym Ed. 2020;31:1961–76. https://doi.org/10.1080/09205063.2020.1787602.

Doménech-Carbo MT, Aura-Castro E. Evaluation of the phase inversion process as an application method for synthetic polymers in conservation work. Stud Conserv. 1999;44:19–28. https://doi.org/10.2307/1506692.

Tekin FS, Çulfaz-Emecen PZ. Controlling Cellulose Membrane Performance via Solvent Choice during Precursor Membrane Formation. ACS Appl Polym Mater. 2023;5:2185–94. https://doi.org/10.1021/acsapm.2c02185.

Cai J, Zhang L. Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol Biosci. 2005;5:539–48. https://doi.org/10.1002/mabi.200400222.

United States Pharmacopeia. General Chapter, 〈2091〉 Weight Variation of Dietary Supplements. Maryland (MD): Rockville; 2023.

United States Pharmacopeia. General Chapter, 〈1216〉 Tablet Friability. Maryland (MD): Rockville; 2022.

United States Pharmacopeia. General Chapter, 〈701〉 Disintegration. Maryland (MD): Rockville; 2023.

United States Pharmacopeia (2023). USP Monographs, Acetaminophen Tablets. Maryland (MD): Rockville; 2023.

Khan GM, Meidan VM. Drug release kinetics from tablet matrices based upon ethylcellulose ether-derivatives: a comparison between different formulations. Drug Dev Ind Pharm. 2007;33:627–39. https://doi.org/10.1080/03639040601179954.

Ilgin P, Ozay H, Ozay O. A new dual stimuli responsive hydrogel: Modeling approaches for the prediction of drug loading and release profile. Eur Polym J. 2019;113:244–53. https://doi.org/10.1016/j.eurpolymj.2019.02.003.

Karthikeyan M, Deepa M, Bassim E, Rahna C, Raj KS. Investigation of kinetic drug release characteristics and in vitro evaluation of sustained-release matrix tablets of a selective COX-2 inhibitor for rheumatic diseases. J Pharm Innov. 2021;16:551–7. https://doi.org/10.1007/s12247-020-09459-9.

Ritger PL, Peppas NA. A simple equation for description of solute release II. Fickian and anomalous release from swellable devices. J Control Release. 1987;5:37–42. https://doi.org/10.1016/0168-3659(87)90035-6.

Chunshom N, Chuysinuan P, Techasakul S, Ummartyotin S. Dried-state bacterial cellulose (Acetobacter xylinum) and polyvinyl-alcohol-based hydrogel: An approach to a personal care material. J Sci: Adv Mater Devices. 2018;3:296–302. https://doi.org/10.1016/j.jsamd.2018.06.004.

Tong Y, Huang S, Meng X, Wang Y. Aqueous-cellulose-solvent-derived changes in cellulose nanocrystal structure and reinforcing effects. Polymers. 2023;15(14):3030. https://doi.org/10.3390/polym15143030.

Ul-Islam M, Khan T, Park JK. Water holding and release properties of bacterial cellulose obtained by in situ and ex situ modification. Carbohydr Polym. 2012;88:596–603. https://doi.org/10.1016/j.carbpol.2012.01.006.

Rebelo AR, Archer AJ, Chen X, Liu C, Yang G, Liu Y. Dehydration of bacterial cellulose and the water content effects on its viscoelastic and electrochemical properties. Sci Technol Adv Mater. 2018;19:203–11. https://doi.org/10.1080/14686996.2018.1430981.

Zhou J, Zhang L, Cai J, Shu H. Cellulose microporous membranes prepared from NaOH/urea aqueous solution. J Membr Sci. 2002;210:77–90. https://doi.org/10.1016/S0376-7388(02)00377-0.

Shanshan G, Jianqing W, Zhengwei J. Preparation of cellulose films from solution of bacterial cellulose in NMMO. Carbohydr Polym. 2012;87:1020–5. https://doi.org/10.1016/j.carbpol.2011.06.040.

Li S, Bashline L, Lei L, Gu Y. Cellulose synthesis and its regulation. The Arabidopsis Book/American Society of Plant Biologists 2014;12: e0169. https://doi.org/10.1199/tab.0169.

Morán JI, Alvarez VA, Cyras VP, Vázquez A. Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose. 2008;15:149–59. https://doi.org/10.1007/s10570-007-9145-9.

Le Pevelen D, Tranter G. FT-IR and raman spectroscopies, polymorphism applications, In: Encyclopedia of Spectroscopy and Spectrometry. New York (NY): Elsevier; 2016.

Mohammadkazemi F. Surface properties of bacterial nanocellulose using spectroscopic methods and X-ray diffraction. Am J Appl Chem. 2015;1:10–3. https://doi.org/10.11648/j.ajaic.20170101.13.

Katepetch C, Rujiravanit R, Tamura H. Formation of nanocrystalline ZnO particles into bacterial cellulose pellicle by ultrasonic-assisted in situ synthesis. Cellulose. 2013;20:1275–92. https://doi.org/10.1007/s10570-013-9892-8.

Bian J, Peng F, Peng X-P, Xiao X, Peng P, Xu F, et al. Effect of [Emim]Ac pretreatment on the structure and enzymatic hydrolysis of sugarcane bagasse cellulose. Carbohydr Polym. 2014;100:211–7. https://doi.org/10.1016/j.carbpol.2013.02.059.

French AD. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose. 2014;21:885–96. https://doi.org/10.1007/s10570-013-0030-4.

Gong J, Li J, Xu J, Xiang Z, Mo L. Research on cellulose nanocrystals produced from cellulose sources with various polymorphs. RSC Adv. 2017;7:33486–93. https://doi.org/10.1039/C7RA06222B.

El Oudiani A, Chaabouni Y, Msahli S, Sakli F. Crystal transition from cellulose I to cellulose II in NaOH treated Agave americana L. fibre. Carbohydr Polym. 2011;86:1221–9. https://doi.org/10.1016/j.carbpol.2011.06.037.

Leng C, Li K, Tian Z, Si Y, Huang H, Li J, et al. Theoretical study of cellulose II nanocrystals with different exposed facets. Sci Rep. 2021;11:21871. https://doi.org/10.1038/s41598-021-01438-5.

Betlej I, Zakaria S, Krajewski K, Boruszewski P. Bacterial cellulose - Properties and its potential application. Sains Malays. 2021;50:493–505. https://doi.org/10.17576/jsm-2021-5002-20.

Tofiq M, Nordström J, Persson AS, Alderborn G. Effect of excipient properties and blend ratio on the compression properties of dry granulated particles prepared from microcrystalline cellulose and lactose. Powder Technol. 2022;399:117207. https://doi.org/10.1016/j.powtec.2022.117207.

Parrot EL. Solid pharmaceuticals, In: Pharmaceutical technology. 3rd ed. Minnesota (MN): Burgess Publishing Company; 1971, pp. 58–106.

Teixeira MT, Sa-Barreto LL, Silva IC, Gratieri T, Gelfuso GM, Marreto RN, et al. The influence of porosity on tablet subdivision. Particuology. 2020;53:192–6. https://doi.org/10.1016/j.partic.2020.06.001.

Johansson B, Alderborn G. The effect of shape and porosity on the compression behaviour and tablet forming ability of granular materials formed from microcrystalline cellulose. Eur J Pharm Biopharm. 2001;52:347–57. https://doi.org/10.1016/s0939-6411(01)00186-2.

Jiménez-Castellanos MR, Zia H, Rhodes CT. Assessment of an in vitro method for measuring the bioadhesiveness of tablets. Int J Pharm. 1993;89:223–8. https://doi.org/10.1016/0378-5173(93)90247-D.

Corveleyn S, Remon JP. Formulation and production of rapidly disintegrating tablets by lyophilisation using hydrochlorothiazide as a model drug. Int J Pharm. 1997;152:215–25. https://doi.org/10.1016/S0378-5173(97)00092-6.

Khan GM, Zhu J-B. Studies on drug release kinetics from ibuprofen–carbomer hydrophilic matrix tablets: influence of co-excipients on release rate of the drug. J Control Release. 1999;57:197–203. https://doi.org/10.1016/s0168-3659(98)00122-9.

Kitazawa S, Johno I, Ito Y, Teramura S, Okada J. Effects of hardness on the disintegration time and the dissolution rate of uncoated caffeine tablets. J Pharm Pharmacol. 1975;27:765–70. https://doi.org/10.1111/j.2042-7158.1975.tb09397.x.

Markl D, Zeitler JA. A review of disintegration mechanisms and measurement techniques. Pharm Res. 2017;34:890–917. https://doi.org/10.1007/s11095-017-2129-z.

Xie F, Ji S, Cheng Z. In vitro dissolution similarity factor (f2) and in vivo bioequivalence criteria, how and when do they match? Using a BCS class II drug as a simulation example. Eur J Pharm Sci. 2015;66:163–72. https://doi.org/10.1016/j.ejps.2014.10.002.

Abdan KB, Yong SC, Chiang ECW, Talib RA, Hui TC, Hao LC. Barrier properties, antimicrobial and antifungal activities of chitin and chitosan-based IPNs, gels, blends, composites, and nanocomposites, In: Handbook of chitin and chitosan. New York (NY): Elsevier; 2020. p. 175–227.

Bruschi ML. Strategies to modify the drug release from pharmaceutical systems. Cambridge: Woodhead Publishing; 2015.

Funding

This work was supported by Walailak University under the new strategic research project (P2P) grant number CGS-P2P-2564–065.

Author information

Authors and Affiliations

Contributions

SK: conceptualization, methodology, investigation, data analysis, visualization, writing – original draft; JC: conceptualization, methodology, investigation, data analysis, visualization, writing – review and editing; WS and TS: methodology, investigation, data analysis, writing – review and editing; CJ: funding acquisition and project administration, conceptualization, methodology, investigation, data analysis, visualization, writing – review and editing; All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaewpradit, S., Chingunpitak, J., Samhadthai, W. et al. Comparison of Properties of Acetaminophen Tablets Prepared by Wet Granulation Using Freeze-Dried Versus Phase-Inversion Bacterial Cellulose as Diluent. AAPS PharmSciTech 25, 32 (2024). https://doi.org/10.1208/s12249-024-02752-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-024-02752-7