Abstract

The use of apex vessels may solve coning problems associated with dissolution testing. However, excessive dissolution acceleration can reduce the discriminatory power. This study aimed to clarify how different apex vessel sizes affect the dissolution behavior of cone-forming formulations. Five apex vessels with different heights, centralities, and compendial vessels were used. The paddle rotation speed at which the coning phenomenon resolved was measured using standard particles of different densities. Three model formulations—USP prednisone tablets, atorvastatin calcium hydrate tablets, and levofloxacin fine granules—were selected, and dissolution tests were conducted at 30–100 revolutions per minute (rpm). Compared to the compendial vessels, the disappearance of standard particles at the apex base at lower paddle speeds in apex vessels was observed. Standard particles tended to remain in the center of the apex vessels and disappear at rotational speeds comparable to those of the compendial vessels. Dissolution increased in an apex height-dependent manner in the model formulations, except for the atorvastatin calcium hydrate tablets at 50 rpm. For levofloxacin fine granules, dissolution was also improved by reducing the paddle agitation speed to 30 rpm in the compendial vessels. Differences in apex centrality by 3 mm did not affect the dissolution rate. Our results indicate that apex vessels with low apex heights have a mount-resolving effect, but the degree of dissolution improvement by avoiding the coning phenomenon depends on the formulation characteristics used in the dissolution tests.

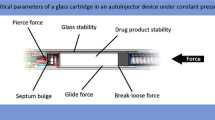

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dissolution testing is an important quality assurance test for solid oral dosage forms specified in the general text harmonized by the Pharmacopeial Discussion Group [1]. Dissolution profiles between the two drug products are evaluated for biowaiver options for additional product strength [2], post-approval changes [3], and a new generic drug based on the biopharmaceutics classification system (BCS) [4, 5]. A paddle apparatus (USP II) is commonly used in biopredictive dissolution testing [6] and in vitro–in vivo correlation [7] in addition to quality control tests and biowaiver applications. Although the paddle apparatus has been thoroughly validated and justified, the hemispherical shape of the vessel bottom sometimes causes the mount formation of drug products at the bottom of vessels during dissolution testing, which is called the “coning” effect [8]. This problem is often observed in products containing large amounts of drugs or insoluble excipients, even when the product contains soluble drug substances [9].

The coning refers to an artificial error observed in vessels during dissolution testing and may not be relevant to in vivo performance [10]. Dissolution tests with coning are less effective for evaluating the formulation property as a quality control test and for comparing the dissolution similarity between the two products. The weak hydrodynamics at the center of the vessel bottom, where drug products typically reside during dissolution tests, is the main cause of the coning [11, 12]. To overcome this problem, several approaches with different sinkers [13] and crescent-shaped spindles [14] were used. A rotating basket apparatus at 100 revolutions per minute (rpm) is often used instead of a paddle apparatus at 50 rpm [15, 16]. However, this can cause some variability in the dissolution test because some disintegrated particles may fall through the basket mesh and settle at the bottom of the vessel [17]. A higher stirring paddle speed of 75 rpm is one of the approaches for solving the coning problem and is allowed for biowaiver applications in some regional guidelines [18]. However, the harmonized BCS-based biowaiver guidelines (ICH M9) do not support the paddle method at 75 rpm because of its low discriminatory power for non-bioequivalent products [19, 20].

Another approach to overcome the coning is the use of an apex vessel developed by Vankel as the Apex vessel™ in 1997, which has a small conical apex at the bottom [21]. The apex shape at the bottom of the vessel can help avoid the disintegrated formulation accumulation in the center of the vessel [22]. Apex vessels have a dramatic mount-resolving effect owing to changes in the hydrodynamic flow at the bottom of the vessel, resulting in faster dissolution rates and reduced variability in dissolution tests [23, 24]. Recently, the USP described the use of apex vessels in dissolution tests in official monographs [25, 26] and mentioned the usefulness of apex vessels in a general chapter <1092> [27]. A case study of an extended-release formulation regarding the relevance of apex vessel dissolution testing for clinical performance was also reported [28]. However, the dissolution rate of highly and poorly soluble drugs at 50 rpm in the apex vessels is as high as that at 60 rpm or 75 rpm in the compendial vessel [23]. The low discriminatory power of the dissolution test in apex vessels has been attributed to an overaccelerated dissolution rate [17, 29]. Therefore, apex vessels have been used only during the development phase and not for quality control dissolution testing in most regions. To use apex vessels more effectively, setting an appropriate apex size that can solve the coning problem without reducing discriminatory power is necessary.

This study aimed to determine the appropriate size of the apex within the apex vessel. We prepared apex vessels of different sizes. The effectiveness of each apex vessel in solving the coning problem was evaluated by measuring the minimum rotational speed required for the disappearance of the coning. Three different commercial products were used as model formulations to evaluate dissolution profiles within the apex vessel.

Materials and Methods

Materials

Five apex vessels with different apices at the bottom were purchased from Toyama Sangyo Co., Ltd. (Osaka, Japan) (Table I; Fig. 1). AV-A, AV-B, AV-C, and AV-D vessels had apices of different heights at their centers. The AV-B/3 vessel had an apex of comparable height to the AV-B vessel but was displaced 3 mm from the center of the vessel. The AV-C, AV-D, and AV-B/3 vessels were not commercially available and were made to order. Three white polyethylene microspheres with different particle densities and mean diameters (1.07–1.13 g/cm3 and 59–80 µm, 1.20–130 g/cm3 and 59–80 µm, and 1.40–150 g/cm3 and 49–67 µm, respectively) and borosilicate solid glass microspheres (2.1–2.3 g/cm3 and 59–80 µm, respectively) were purchased from Cospheric LLC (CA, USA).

Dissolution Tests

Dissolution tests of the USP Prednisone Tablet RS (Lot no. R132B0; US Pharmacopeial Convention, Rockville, MD, USA), atorvastatin calcium hydrate tablets 10 mg (Lipitor® tablets, Lot no. 21009N1; Viatris Inc., Tokyo, Japan), and levofloxacin fine granules 10% (Cravit® fine granules tablets, Lot no. QXA0090; Daiichi Sankyo Co., Ltd., Tokyo, Japan) were performed in a USP II apparatus (paddle) (Toyama Sangyo Co., Ltd.) with compendial vessels or apex vessels at a paddle speed of 30 rpm, 50 rpm, and 75 rpm in 900 mL of purified water at 37 ± 0.5 °C. The dissolution test was performed using 1 g formulation (levofloxacin fine granules) or one tablet (other formulations) per vessel. The paddle height was set at 25 mm from the bottom of the compendial vessel and was unchanged in all the apex vessels. At each sampling time, 20 mL of medium was replaced by removing and filtering through a 0.45-µm hydrophilic polytetrafluoroethylene filter.

Dissolved drug concentrations were determined at an absorbance at 242 nm (prednisone) and 289 nm (levofloxacin) using an ultraviolet spectrophotometer (UV2700, Shimadzu Co., Kyoto, Japan). The concentration of atorvastatin calcium was determined using high-performance liquid chromatography (Prominence, Shimadzu Co.). The mobile phase was prepared by adding 270 mL acetonitrile and 200 mL tetrahydrofuran to 530 mL of 0.05 M ammonium citrate buffer (pH 4.0). A Mightysil RP-18GP column (250 × 4.6 mm, 5 µm; Kanto Chemical Co., Tokyo, Japan) was used at 30 °C. The flow rate was set to adjust the retention time of atorvastatin to approximately 9 min, and the injection volume was 50 µL. Measurements were performed at a detection wavelength of 244 nm.

Measurement of the Minimum Revolutions per Minute at Which the Coning Phenomenon Disappeared

No coning rpm (NCrpm; the minimum revolutions per minute at which the coning phenomenon disappeared) was measured according to a previous report, with slight modifications [30]. A suspension of 0.10 g was prepared in 8 mL of 0.1% (w/v) sodium dodecyl sulfate in phosphate-buffered saline. This was then added to 892 mL of 0.1% (w/v) polysorbate 80 (PS80) in the Japanese Pharmacopoeia 2nd fluid in the compendial and apex vessels with gentle paddle agitation. USP apparatus II was used to maintain the fluid at 37 °C. Before measuring NCrpm, the paddle rotation was stopped to allow the standard particles to sink. The rotational speed of the paddle was gradually increased from 30 rpm in 5-rpm steps until the coning was no longer visible. Coning formation and dissolution are also affected by the viscosity of test solution [31, 32]. The viscosity of 1% (w/v) PS80 in the Japanese Pharmacopeial 2nd fluid was measured using an Ubbelohde-type viscometer and was found to be low (0.74 mPa⋅s). Therefore, the test fluid used for NCrpm measurement had a low viscosity [33].

Statistical Analysis

NCrpm of the compendial vessels was compared with those at the top and base of the apex vessels at each particle size of standard particle. NCrpm data were analyzed using two-way repeated-measures analysis of variance, followed by Bonferroni’s multiple comparison test using EZR (version 1.61) (Saitama Medical Center, Jichi Medical University, Saitama, Japan), which is a graphical user interface for R (The R Foundation for Statistical Computing, Vienna, Austria). More precisely, it is a modified version of R commander designed to add statistical functions frequently used in biostatistics.

f 2 Calculations

Dissolution similarities were evaluated using the similarity factor (f2) in accordance with FDA guidelines [34].

Results

Effect of Standard Particle and Apex Size on the Mount-Resolving Effect

NCrpm was measured using standard particles with different particle densities in the compendial and apex vessels to investigate the efficiency of the apex vessels in dispersing mount formation during the dissolution tests (Fig. 2). The NCrpm value of the compendial vessel increased with increasing particle density, indicating that a higher stirring force was required to disperse the mount at higher particle densities. Mount formation was observed in the apex vessel at both the base and top of the apex. As the rotational speed increased, the mount at the apex base dispersed first, leaving the mount at the apex top. NCrpm at the base of the apex was significantly lower in the apex vessels than in the compendial vessels. Similarly, NCrpm at the top of the apex increased in proportion to the particle density but had a smaller slope than that of the compendial vessel, indicating that the apex vessel resisted mount formation due to the increased particle density. The NCrpm at the top of the apex vessel was comparable to that at the bottom of the compendial vessel when the particle density was < 1.5 g/cm3, whereas the NCrpm at the top of the apex vessel was higher than that at the base, regardless of the particle density. The reduced NCrpm at the top of the apex in the AV-A and AV-B vessels was observed when using 2.2 g/cm3 standard particles. The high density of standard particles and the high apex could contribute to the difficulty of standard particles returning to the top of the apex after falling from the top to the base.

Correlation between the particle density of standard particles and NCrpm in various vessels. Closed and open bars indicate NCrpm at the center of vessels and at the base of the apex vessels, respectively. *p < 0.01, significantly different from the NCrpm of compendial vessel (ComV) at each particle size. Each result represents the mean ± SD from triplicated experiments

Effect of Apex Size on Dissolution Rate

We used several model formulations to evaluate the effect of apex vessels on dissolution rate and mount formation.

Disintegrating Tablets: USP Prednisone Tablets and Amlodipine Besylate Tablets

USP prednisone tablets are well-known disintegrating tablets that are often used as model tablets to evaluate the dissolution test conditions. All apex vessels showed faster dissolution than compendial vessels at 30 rpm and 50 rpm (Fig. 3a, b). A apex size–dependent dissolution was observed at 50 rpm but not at 75 rpm (Fig. 3c). Dissolution in apex vessels with a high apex (AV-A, AV-B, and AV-C) at 50 rpm was fast and showed similarity to the compendial vessel at 75 rpm (Table II). Prednisone tablets in compendial and apex vessels of all sizes at 75 rpm dissolved more than 85% in 30 min, and no difference in the dissolution rate between the vessels was observed (Fig. 3c). In the dissolution test of amlodipine besylate tablets, other model products showing coning problems in the paddle apparatus at 50 rpm and apex size–dependent dissolution in apex vessels at 50 rpm were also observed (Fig. 4). As with prednisone tablets, amlodipine besylate tablets showed similar dissolution in apex vessels at 50 rpm to that in compendial vessels at 75 rpm (Table II).

Sticking Tablets: Atorvastatin Calcium Hydrate Tablets

Atorvastatin tablets adhered to the base of the vessels and dissolved without sufficient dispersion. Furthermore, a small amount of the tablet formulation was observed at the top of the apex in the apex vessel (Supplementary Fig. 1). Atorvastatin tablets reached a dissolution plateau within 15 min under all test conditions (Fig. 5). The apex vessels showed faster dissolution than the compendial vessels at 50 rpm and dissolution similarity except for the AV-C vessels at 75 rpm (Table II). The AV-A vessel did not necessarily show the fastest dissolution among the apex vessels, indicating apex size–independent dissolution. Notably, this may be attributed to the position of the tablets attached to the top or base of the apex at the start of the dissolution test. Similar to prednisone tablets, the dissolution profiles of atorvastatin tablets in the compendial vessel at 75 rpm showed similar dissolution in the AV-A and AV-B vessels, with a high apex at 50 rpm (Table II).

Formulations with a Large Volume of Excipients: Levofloxacin Fine Granules 10%

Fine levofloxacin granules are formulations containing large amounts of insoluble excipients and microcrystalline cellulose. The formulation accumulated at the center and bottom of the vessels at 50 rpm and covered the apex of the vessels during the dissolution test (Supplementary Fig. 2). Dissolution was slow in the compendial vessel at 50 rpm and 75 rpm because of the coning (Fig. 6b, c), and the dissolution at 60 min was approximately 50% and 77% at 50 rpm and 75 rpm, respectively. However, the coning problem was not resolved at 50 rpm for AV-D even when an apex vessel was used, and the dissolution was slow. A size-dependent improvement in dissolution was observed in the larger apex vessels AV-A, AV-B, and AV-C (Fig. 6b). At 30 rpm, dissolution significantly improved in both the small apex vessels, AV-D, and the compendial vessels (Fig. 6a). Furthermore, no difference in the dissolution rate between the apex and compendial vessels or in the apex size was observed. The formulation did not accumulate in the center of the bottom of the vessel but spread out at the bottom of the vessel (Supplementary Fig. 2).

Effect of Apex Centering on Dissolution Rate

We used another shape of the apex vessels, AV-B/3, in which the apex of the AV-B vessels deviated 3 mm from the center. No difference in the dissolution of prednisone tablets and levofloxacin fine granules between the AV-B and AV-B/3 vessels at 30–100 rpm was observed (Fig. 7).

Discussion

The commercially available apex vessels have large apices. The present study clearly suggests that even smaller apex sizes can solve the coning problem with a particle density range of 1.1–2.2 g/cm3. Notably, crystalline cellulose and precipitated calcium carbonate with particle densities of 1.6 g/cm3 and 2.7–2.9 g/cm3, respectively, are the main insoluble excipients that cause coning problems in atorvastatin calcium tablets and levofloxacin fine granules [35, 36]. Although standard particles with densities > 2.2 g/cm3 were not examined in this study, the increase in NCrpm with increasing particle density indicates that the apex vessels used in the study may be effective in resolving the coning during the dissolution testing of actual product formulations. In contrast, mount formation was observed at the top of the apex, and the NCrpm of the apex vessels was comparable to that of the compendial vessels. Lower NCrpm was observed for the high apex (AV-A, AV-B, and AV-C) using standard high-density particles (2.2 g/cm3), which may be due to a decrease in the number of standard particles from the top of the apex. Therefore, a higher apex would be helpful in efficiently avoiding the coning phenomenon on the apex top. In addition, the disintegrated formulations may have different particle sizes and shapes than the standard particles used in this study, and the particle size of the disintegrated formulations gradually decreased during the dissolution tests [37]. NCrpm is affected by particle size and shape [30, 38, 39]. Large amounts of the formulation may cover the apex, causing a loss of effectiveness. Therefore, an actual formulation with the same particle density as the standard particles may show different NCrpm values.

All formulations tested in this study dissolved faster in the apex vessels than in the compendial vessels at 50 rpm, indicating a dramatic improvement in the dissolution rate. Therefore, apex vessels are useful for overcoming the reduced dissolution caused by the coning in compendial vessels, regardless of the apex size. This is consistent with the finding that NCrpm is lower at the base of the apex than at the center of the compendial vessel. This result also indicates the importance of separately evaluating NCrpm at the top and base of the apex vessel. Mount formation was observed mainly at the base of the apex vessel. Therefore, a correlation between NCrpm at the base of apex vessels and dissolution rate was observed. Meanwhile, the dissolution rate of prednisone tablets at 50 rpm in the AV-A or AV-B vessels was as high as that at 75 rpm in the compendial vessel. This result is consistent with a previous report that a faster paddle speed of 75 rpm in the compendial vessel results in a dissolution rate of both highly soluble and poorly soluble drugs, comparable to a slower paddle speed of 50 rpm in the apex vessel [23]. The high stirring paddle speed in the compendial vessel can cause some non-bioequivalent formulations to be judged as bioequivalent owing to rapid dissolution [19, 20, 40]. Therefore, sufficient discriminative ability of the test conditions should be considered [41,42,43,44] while using apex vessels with a high apex for addressing coning issues. The ICH-M9 guidelines do not allow a paddle speed of 75 rpm, even if coning problems occur, because of the risk of non-bioequivalent formulations being judged to be bioequivalent [5]. USP stimulus have been used to identify poorly manufactured formulations, such as slow variants or formulations contain large particles [21]. Therefore, apex vessels are useful for resolving coning issues in quality control specification testing [45]. Nevertheless, reports on the usefulness of apex vessels for discriminating non-bioequivalent products in dissolution tests for biowaivers are limited. Further studies are needed to demonstrate the validity of apex vessels to resolve the coning problem for biowaiver validation.

Effect of the apex to reduce the mount formation, studied using the several apex size vessels, varied between the formulations. NCrpm indicated that AV-D vessels, as well as AV-A, AV-B, and AV-C vessels, had a mount-resolving effect (Fig. 2). The dissolution rate of prednisone and amlodipine tablets, but not that of atorvastatin tablets and levofloxacin fine granules, was improved in the AV-D vessels. For atorvastatin tablets, a large proportion of dissolution was observed within 15 min, and the dissolution reached a plateau. This indicates that only the dispersed drug particles dissolved immediately after the start of the dissolution test. The apex size of the AV-D vessels was smaller than that of the other apex vessels, and the atorvastatin tablets tended to fall near the center of the vessel. Therefore, the extent of dispersion in the AV-D vessels immediately after the start of the dissolution test was considered small. In contrast, the standard particles used in the NCrpm evaluation exhibited good dispersion with low aggregation and adhesion. This difference in particle characteristics was thought to have led to a lack of correlation between NCrpm and the dissolution results. The levofloxacin fine granules formed a conical mount in the center of the compendial vessel at 50 rpm (Supplementary Fig. 2). However, when the AV-A vessel was used, the formulation covered the apex from base to top. In other words, the presence of the apex increased the surface area of the formulation by increasing the size of the cone, which was believed to contribute to improved dissolution in the apex vessel. The apex volume of the AV-D vessel was calculated from the diameter and height to be approximately 1/8 of that of the AV-C vessels. Therefore, the change in the size of the mount cone due to the presence of the apex was small in the AV-D vessels. This may have contributed to the smaller improvement in the dissolution of levofloxacin fine granules in AV-D than in the other apex vessels. In addition, the dissolution was improved by reducing the paddle agitation speed to 30 rpm in the compendial vessel. Therefore, the optimal test conditions for solving dissolution problems, including coning problems and formulation adhesion, should be selected based on formulation characteristics [46,47,48] and not necessarily be focused toward an apex vessel at 50 rpm.

Irregular internal shape of the vessel and the deviation of shaft centering can greatly affect the dissolution rate [49,50,51]. The vessel/shaft centering from the vertical was set at ≤ 2.0 mm in the internationally harmonized procedure of the Pharmacopeial Discussion Group [1]. The USP stimuli also recommend a tolerance of ± 2 mm of apex centering relative to the vessel center [21]. In this study, the deviation of apex centering by 3 mm in AV-B did not significantly affect the dissolution of prednisone tablets and levofloxacin fine granules 10%. Therefore, a 3-mm deviation from the apex would not cause a dissolution difference. The base diameters of the apices of the AV-A and AV-B vessels were approximately 34 mm and 24 mm, respectively. We chose AV-B vessels for the off-centered apex vessels and created AV-B/3 vessels because AV-B vessels were initially expected to be the most effective, that is, with mild agitation conditions and efficient mount-resolving effects. However, AV-C and AV-D, which had smaller apex diameters than AV-A and AV-B, also showed mount-resolving effects. The tolerance of apex centering in apex vessels with a low-height apex may need to be examined.

The proposed specifications for apex height reported in the USP stimuli are 15 ± 2 mm from the outer bottom of the vessel to the inner height of the apex, with a 90° angle [21]. In contrast, the apex height of the apex vessel used in this study was determined from the thickness of the flange, the depth from the underside of the flange, and the radius of the hemispherical bottom (Supplementary Fig. 3). Although the methods used to measure apex height differ between these apex vessels, AV-A vessels are expected to have an apex height similar to that of the apex vessels introduced in the USP stimuli. Considering the small difference in the dissolution rate between the AV-A and AV-B vessels, the effect of the different apex heights between the AV-A and apex vessel in the USP stimuli on the dissolution rate is small. Differences in the apex angle and diameter would affect the amount of coning on the apex top. The apex vessel used in this study had a larger angle than the apex vessel reported for USP stimuli because the apex vessel used in this study was manufactured using a 100° mold. Owing to larger apex angles, the apex top of the vessel may be more prone to coning problems than the apex vessel of the USP stimuli.

Conclusions

In this study, apex vessels with different apex sizes were used to investigate the effect of apex height on coning and dissolution rates in the USP apparatus II. The apex vessels dispersed the coning particles regardless of the apex size. An apex height–dependent increase in dissolution was observed in the model formulations, except for the atorvastatin calcium hydrate tablets at 50 rpm. These results indicate that apex vessels with low apex heights have a mount-resolving effect, but the degree of dissolution improvement by avoiding the coning phenomenon depends on the formulation characteristics used in the dissolution tests.

Data Availability

Data supporting this study’s findings are available from the corresponding author upon request.

Change history

29 February 2024

A Correction to this paper has been published: https://doi.org/10.1208/s12249-024-02770-5

References

International Conference on Harmonisation; Guidance on Q4B evaluation and recommendation of pharmacopoeial texts for use in the International Conference on Harmonisation Regions; Annex 7 on Dissolution Test General Chapter; availability. Notice. Fed Regist. 2010;75:17148–9.

Suarez-Sharp S, Delvadia PR, Dorantes A, Duan J, Externbrink A, Gao Z, et al. Regulatory perspectives on strength-dependent dissolution profiles and biowaiver approaches for immediate release (IR) oral tablets in new drug applications. AAPS J. 2016;18:578–88. https://doi.org/10.1208/s12248-016-9893-2.

Langer C, Diaz DA, Van Alstine L, Bandi N, Fitzgerald S, Colgan S. Analysis of the regulatory divergence of comparative dissolution requirements for post-approval manufacturing changes of modified release solid oral dosage forms. AAPS J. 2019;22:2. https://doi.org/10.1208/s12248-019-0383-1.

Abend AM, Zhang L, Fredro-Kumbaradzi E, Hoffelder T, Cohen MJ, Anand O, et al. Current approaches for dissolution similarity assessment, requirements, and global expectations. AAPS J. 2022;24:50. https://doi.org/10.1208/s12248-022-00691-4.

International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) M9: Biopharmaceutics classification system-based biowaiver. Available from: https://www.ich.org/page/multidisciplinary-guidelines. Accessed 7 Sept 2023.

Mann J, Dressman J, Rosenblatt K, Ashworth L, Muenster U, Frank K, et al. Validation of dissolution testing with biorelevant media: an OrBiTo study. Mol Pharm. 2017;14:4192–201. https://doi.org/10.1021/acs.molpharmaceut.7b00198.

Figueroa-Campos A, Sánchez-Dengra B, Merino V, Dahan A, González-Álvarez I, García-Arieta A, et al. Candesartan cilexetil in vitro-in vivo correlation: predictive dissolution as a development tool. Pharmaceutics. 2020;12. https://doi.org/10.3390/pharmaceutics12070633.

Bai G, Wang Y, Armenante PM. Velocity profiles and shear strain rate variability in the USP dissolution testing apparatus 2 at different impeller agitation speeds. Int J Pharm. 2011;403:1–14. https://doi.org/10.1016/j.ijpharm.2010.09.022.

Hofsäss MA, Dressman J. Evaluation of differences in dosage form performance of generics using BCS-based biowaiver specifications and biopharmaceutical modeling-case examples amoxicillin and doxycycline. J Pharm Sci. 2020;109:2437–53. https://doi.org/10.1016/j.xphs.2020.04.011.

Bai G, Armenante PM. Velocity distribution and shear rate variability resulting from changes in the impeller location in the USP dissolution testing apparatus II. Pharm Res. 2008;25:320–36. https://doi.org/10.1007/s11095-007-9477-z.

Todaro V, Persoons T, Grove G, Healy AM, D’Arcy DM. Characterization and simulation of hydrodynamics in the paddle, basket and flow-through dissolution testing apparatuses - a review. Dissolution Technol. 2017;24:24–36. https://doi.org/10.14227/DT240317P24.

Bai G, Armenante PM, Plank RV, Gentzler M, Ford K, Harmon P. Hydrodynamic investigation of USP dissolution test apparatus II. J Pharm Sci. 2007;96:2327–49. https://doi.org/10.1002/jps.20818.

Mansuroglu Y, Dressman JB. Investigation of dissolution performance of hard gelatin capsule products using various sinkers. Dissolution Technol. 2020;27:21–32. https://doi.org/10.14227/DT270320P21.

Qureshi SA. Choice of rotation speed (rpm) for bio-relevant drug dissolution testing using a crescent-shaped spindle. Eur J Pharm Sci. 2004;23:271–5. https://doi.org/10.1016/j.ejps.2004.08.001.

Abend A, Xiong L, Zhang X, Frankenfeld C, Kesisoglou F, Reuter K, et al. Biowaiver applications in support of a polymorph during late-stage clinical development of verubecestat-current challenges and future opportunities for global regulatory alignment. AAPS J. 2019;22:17. https://doi.org/10.1208/s12248-019-0396-9.

Cardot JM, Garcia Arieta A, Paixao P, Tasevska I, Davit B. Implementing the biopharmaceutics classification system in drug development: reconciling similarities, differences, and shared challenges in the EMA and US-FDA-recommended approaches. AAPS J. 2016;18:1039–46. https://doi.org/10.1208/s12248-016-9915-0.

Gray V, Kelly G, Xia M, Butler C, Thomas S, Mayock S. The science of USP 1 and 2 dissolution: present challenges and future relevance. Pharm Res. 2009;26:1289–302. https://doi.org/10.1007/s11095-008-9822-x.

Crane C, Santos GML, Fernandes EAF, Simon C, Tam A, Triana DG, et al. The requirements for additional strength biowaivers for immediate release solid oral dosage forms in international pharmaceutical regulators programme participating regulators and organisations: differences and commonalities. J Pharm Pharm Sci. 2019;22:486–500. https://doi.org/10.18433/jpps30724.

Garcia-Arieta A, Gordon J, Gwaza L, Mangas-Sanjuan V, Álvarez C, Torrado JJ. Agitation rate and time for complete dissolution in BCS biowaivers based on investigation of a BCS biowaiver for dexketoprofen tablets. Mol Pharm. 2015;12:3194–201. https://doi.org/10.1021/acs.molpharmaceut.5b00131.

Colón-Useche S, González-Álvarez I, Mangas-Sanjuan V, González-Álvarez M, Pastoriza P, Molina-Martínez I, et al. Investigating the discriminatory power of BCS-biowaiver in vitro methodology to detect bioavailability differences between immediate release products containing a class I drug. Mol Pharm. 2015;12:3167–74. https://doi.org/10.1021/acs.molpharmaceut.5b00076.

Mann J, Michael C, Andreas A, Carrie C, Lee A, Robert S, et al. Stimuli to the revision process: the case for apex vessels. Pharm Forum. 2021;47(6).

Collins CC, Nair RR. Comparative evaluation of mixing dynamics in USP apparatus 2 using standard USP vessels and PEAK vessels. Dissolution Technol. 1998;5:18–21. https://doi.org/10.14227/DT050298P17.

Mirza T, Yatindra J, Liu Q, Richard V. Evaluation of dissolution hydrodynamics in the USP, Peak™ and flat-bottom vessels using different solubility drugs. Dissolution Technol. 2005;12:11–4. https://doi.org/10.14227/DT120105P11.

Beckett AH, Quach TT, Kurs GS. Improved hydrodynamics for apparatus 2. Dissolution Technol. 1996;3:7–18. https://doi.org/10.14227/DT030296P7.

US Pharmacopeial Convention. USP monographs, aprepitant capsules. Rockville: US Pharmacopeial Convention; 2020. p. 362.

Convention UP. USP monographs, galantamine tablets. Rockville: US Pharmacopeial Convention; 2020. p. 2081.

US Pharmacopeial Convention. <1092> The dissolution procedure: development and validation. Rockville: US Pharmacopeial Convention; 2020. p. 7707.

Mann J, Cohen M, Abend A, Coutant C, Ashworth L, Shaw R, et al. Stimuli to the revision process: the case for apex vessels stimuli articles do not necessarily reflect the policies of the USPC or the USP Council of Experts. Dissolution Technol. 2021;28:6. https://doi.org/10.14227/DT280421P6.

Baxter JL, Kukura J, Muzzio FJ. Shear-induced variability in the United States Pharmacopeia apparatus 2: modifications to the existing system. AAPS J. 2005;7:E857-64. https://doi.org/10.1208/aapsj070483.

Higuchi M, Yoshihashi Y, Tarada K, Sugano K. Minimum rotation speed to prevent coning phenomena in compendium paddle dissolution apparatus. Eur J Pharm Sci. 2014;65:74–8. https://doi.org/10.1016/j.ejps.2014.09.010.

Pepin X, Goetschy M, Abrahmsén-Alami S. Mechanistic models for USP2 dissolution apparatus, including fluid hydrodynamics and sedimentation. J Pharm Sci. 2022;111:185–96. https://doi.org/10.1016/j.xphs.2021.10.006.

D’Arcy DM, Persoons T. Understanding the potential for dissolution simulation to explore the effects of medium viscosity on particulate dissolution. AAPS PharmSciTech. 2019;20:47. https://doi.org/10.1208/s12249-018-1260-4.

Higuchi M, Terada K, Sugano K. Coning phenomena under laminar flow. Eur J Pharm Sci. 2015;80:53–5. https://doi.org/10.1016/j.ejps.2015.08.004.

US-FDA. Guidance for industry, dissolution testing of immediate release solid oral dosage forms. 1997.

PubChem. Calcium carbonate. Available from: https://pubchem.ncbi.nlm.nih.gov/compound/Calcium-Carbonate. Accessed 7 Sept 2023.

Sun CC. True density of microcrystalline cellulose. J Pharm Sci. 2005;94:2132–4. https://doi.org/10.1002/jps.20459.

Dvorácková K, Rabisková M, Masteiková R, Muselík J, Krejcová K. Soluble filler as a dissolution profile modulator for slightly soluble drugs in matrix tablets. Drug Dev Ind Pharm. 2009;35:930–40. https://doi.org/10.1080/03639040802710243.

Higuchi M, Nishida S, Yoshihashi Y, Tarada K, Sugano K. Prediction of coning phenomena for irregular particles in paddle dissolution test. Eur J Pharm Sci. 2015;76:213–6. https://doi.org/10.1016/j.ejps.2015.05.019.

Zwietering TN. Suspending of solid particles in liquid by agitators. Chem Eng Sci. 1958;8:244–53. https://doi.org/10.1016/0009-2509(58)85031-9.

Hofsäss MA, Dressman JB. The discriminatory power of the BCS-based biowaiver: A retrospective with focus on essential medicines. J Pharm Sci. 2019;108:2824–37. https://doi.org/10.1016/j.xphs.2019.04.030.

Fu M, Conroy E, Byers M, Pranatharthiharan L, Bilbault T. Development and validation of a discriminatory dissolution model for an immediately release dosage form by DOE and statistical approaches. AAPS PharmSciTech. 2021;22:140. https://doi.org/10.1208/s12249-021-02011-z.

Bhatt S, Roy D, Kumar M, Saharan R, Malik A, Saini V. Development and validation of in vitro discriminatory dissolution testing method for fast dispersible tablets of BCS class II drug. Turk J Pharm Sci. 2020;17:74–80. https://doi.org/10.4274/tjps.galenos.2018.90582.

Dharani S, Barakh Ali SF, Afrooz H, Khan MA, Rahman Z. Development and validation of a discriminatory dissolution method for rifaximin products. J Pharm Sci. 2019;108:2112–8. https://doi.org/10.1016/j.xphs.2019.01.020.

Cristofoletti R, Dressman JB. Dissolution methods to increasing discriminatory power of in vitro dissolution testing for ibuprofen free acid and its salts. J Pharm Sci. 2017;106:92–9. https://doi.org/10.1016/j.xphs.2016.06.001.

Gray V, Abend A, Alasandro M, Armenante P, Carducci T, Crist B, et al. Dissolution best practices and international harmonization-AAPS workshop report. Dissolution Technol. 2022;29:230–6. https://doi.org/10.14227/DT290422P230.

Dong X, Tsong Y, Shen M. Statistical considerations in setting product specifications. J Biopharm Stat. 2015;25:280–94. https://doi.org/10.1080/10543406.2014.972511.

Anumolu PD, Sunitha G, Bindu SH, Satheshbabu PR, Subrahmanyam CV. Development and validation of discriminating and biorelevant dissolution test for lornoxicam tablets. Indian J Pharm Sci. 2015;77:312–20. https://doi.org/10.4103/0250-474x.159653.

International Conference on Harmonisation; Guidance on Q6A specifications: test procedures and acceptance criteria for new drug substances and new drug products: chemical substances. Notice. Fed Regist. 2000;65:83041–63.

Tanaka M, Fujiwara H, Fujiwara M. Effect of the irregular inner shape of a glass vessel on prednisone dissolution results. Dissolution Technol. 2005;12:15–9. https://doi.org/10.14227/DT120405P15.

Scott P. Geometric irregularities common to the dissolution vessel. Dissolution Technol. 2005;12:18–21. https://doi.org/10.14227/DT120105P18.

Baxter JL, Kukura J, Muzzio FJ. Hydrodynamics-induced variability in the USP apparatus II dissolution test. Int J Pharm. 2005;292:17–28. https://doi.org/10.1016/j.ijpharm.2004.08.003.

Funding

This research was partly supported by AMED under Grant Number JP22mk0101221.

Author information

Authors and Affiliations

Contributions

HY made substantial contributions to the conception of the work, the analysis, interpretation of data for the work, and drafting the original manuscript. TM, YA, and KI contributed to the conception of the work and revising the manuscript critically for important intellectual content. AI and NT contributed to the acquisition and analysis of the data for the work. YS contributed to the statistical analysis plan, revising the manuscript, and final approval of the version to be published.

All authors have approved the submitted version of the manuscript and agreed to be accountable for any part of the work.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised due to a retrospective Open Access order.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yoshida, H., Morita, T., Abe, Y. et al. Effects of Apex Size on Dissolution Profiles in the USP II Paddle Apparatus. AAPS PharmSciTech 25, 9 (2024). https://doi.org/10.1208/s12249-023-02722-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-023-02722-5