Abstract

Polysorbates (PS) are nonionic surfactants that are commonly included in protein formulations to mitigate the formation of interfacial stress-induced protein particles and thus increase their long-term storage stability. Nonetheless, factors that dictate the efficiency of different polysorbates in mitigating protein particle formation, especially during the application of interfacial stresses, are often ill defined. Here, we used a Langmuir trough to determine the surface activity of two IgG1 monoclonal antibodies formulated with two different polysorbates (PS20 and PS80) when subjected to interfacial dilatational stress. Interfacial properties of these formulations were then correlated with characterization of subvisible protein particles measured by micro-flow imaging (MFI). Both mAbs, when formulated in PS20, demonstrate faster adsorption kinetics and higher surface activity compared to PS80 or surfactant-free formulations. Compression/expansion results suggest that when exposed to interfacial dilatational stresses, both mAb/PS20 formulations display interfacial properties of PS20 alone. In contrast, interfacial properties of both mAb/PS80 formulations suggest mAbs and PS80 are co-adsorbed to the air–water interface. Further, MFI analysis of the interface and the bulk solution confirms that PS20 is more effective than PS80 at mitigating the formation of larger particles in the bulk solution in both mAbs. Concomitantly, the efficiency of PS to prevent interface-induced protein particle formation also depended on the protein’s inherent tendency to aggregate at a surfactant-free interface. Together, the studies presented here highlight the importance of determining the interfacial properties of mAbs, surfactants, and their combinations to make informed formulation decisions about the choice of surfactant.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Monoclonal antibody (mAb) therapeutics represent a notable class of marketed drug products that are capable of effectively treating a large variety of diseases ranging from autoimmune diseases to oncology, to neurogenerative disease, and to, most recently, COVID-19 [1, 2]. However, the physical and chemical stability of mAbs is often compromised due to exposure to mechanical and chemical stresses during the manufacturing, shipping, storage, and administration processes. Stress-induced protein degradation pathways ultimately result in the formation of subvisible and visible particles [3]. Degradation of mAbs and formation of protein particle aggregates may reduce a drug product’s safety and efficacy, cause adverse side effects, and trigger unwanted immune responses when administered to patients [4, 5]. As a result, the United States Pharmacopeia (USP) requirements for standard subvisible particle tests require that particulates > 10 and > 25 µm in size be controlled below certain levels (in 100 mL solution, there should be less than 6000 particles for particles in the size range greater than10 µm and less than 600 particles for particles greater than 25 µm) and stress that analysis of number, size, and morphology of protein particulates is critically important [4, 6]. More recently, there has also been consensus that subvisible particles < 10 µm should also be assessed due to similar concerns of loss of efficacy and enhanced immunogenicity. Therefore, understanding and employing mitigation strategies to control protein degradation and formation of subvisible and visible particulates have become a focus for the biotechnology and academic sectors [4, 7].

Protein degradation and subsequent particulate formation can be induced by a variety of mechanisms. Aggregation of proteins in the bulk solution has been extensively studied and has been shown to depend on temperature and solution conditions (pH, buffer type, and ionic strength). Additionally, the role of the air–water (a/w) interface in inducing formation of protein particles, while less understood, is acknowledged as playing a significant role in protein particle formation. As a result, the most common mitigation strategy to reduce interfacial stress-induced protein particle formation in protein therapeutic formulations is the inclusion of surfactants [8,9,10,11].

Typically, nonionic surfactants such as polysorbate 20 (PS20) and polysorbate 80 (PS80) are added to protein therapeutic formulations to decrease aggregation and mitigate subvisible and visible particle formation when subjected to various stress conditions [12,13,14,15]. While the ability of polysorbates to mitigate protein particle formation is well documented in literature, the details of how the surfactants prevent protein aggregation at the interface are not fully understood. It has been proposed that surfactants protect mAbs from aggregating into larger structures by either preferentially adsorbing to the a/w interface or by forming protein-surfactant complexes which prevent interfacial adsorption of protein molecules [14, 16,17,18]. Recent findings by Kanthe et. al support that competitive adsorption between the surfactant. Additionally, studies have shown that surfactants prevent the formation of an interfacial gel layer in a variety of protein solutions [19,20,21] at air–water and liquid–liquid interfaces. However, recent studies have shown that the level of protection may depend on the type of surfactant used in the formulation, which in turn impacts the competitive adsorption of the surfactant and the proteins to the air–water interface [18, 22, 23].

In our previous work, we applied a Langmuir trough-based approach to understand how surfactants mitigate interface-induced particle formation in mAb solutions when formulated with different grades of PS80 [24]. A Langmuir trough allows for application of dilatational stress to the interface alone without disturbing the bulk solution. Correlating changes in the interfacial properties with a complete analysis of protein particle formation allowed us to gain fundamental insight into the process of interface-induced protein particle formation. Our results showed that dilatational stress isolated at the air–water interface in mAb solutions led to a dramatic increase in subvisible and visible particles in the bulk. Addition of PS80 to these formulations significantly decreased the number of larger particles irrespective of PS80 grade especially for an mAb that was originally less stable at the interface [24].

In the current study, we apply the same techniques and analysis in determining the effect of the two different non-ionic surfactants, namely, PS20 and PS80, on the interfacial properties and the rate of particle formation observed in these two mAb formulations. Both types of polysorbates are primarily composed of fatty acid esters of polyoxyethylenesorbitan and are amphiphilic molecules. PS20 and PS80 share a common backbone and only have differences in their hydrophobic fatty acid side chains where PS20 contains mostly lauric acid and PS80 contains mostly oleic acid. Due to the difference in their chain length and therefore their hydrophobicity, these surfactants also demonstrate a difference in their interfacial properties and surface activity. We investigate the efficacy of PS20 vs. PS80 in preventing interface-induced protein particle formation by measuring the interfacial response of two different mAbs solutions to unstressed and stressed conditions in a Langmuir trough and correlating interfacial data with characterization of protein particle formation, as measured with MFI techniques.

Materials and Methods

Materials

Monoclonal antibodies (mAb) mAb1(IgG) and mAb2 (IgG) were provided by Bristol-Myers Squibb (BMS, New Brunswick, NJ). mAb1 is formulated in phosphate buffer pH 6.5 at ~ 45 mg/mL while mAb2 is formulated in histidine buffer at pH 6 at ~ 20 mg/mL. PS20 and PS80 were purchased from commercial sources and provided by BMS. PS20 (super-refined) was purchased from CRODA while PS80 (with > 99.5% oleic acid) was sourced from NOF America Corporation. All solutions were made using ultrapure water (18.2 MΩ-mm, EMDD Millipore, Billerica, MA). When not in use, all stock solutions of proteins and surfactants were stored at 4 °C in a refrigerator in vials and protected from light to prevent photodegradation.

Sample Preparation

In this work, a final protein concentration of 0.5 mg/mL was used for all experiments involving mAbs. This concentration was chosen based on previous studies and allowed us to perform all the experiments while optimizing material usage [7, 25]. These studies have also shown that low protein concentrations can still result in interfacial stress-induced particle formation in mAb formulations, and 0.5 mg/mL solutions of mAb1 and mAb2 were prepared fresh each time using filtered PBS buffer at pH 7.6 to dilute the original stock protein solutions. The mAb solutions were then filtered using 0.22 µm sterile Millex-VV syringe filters (Merck Millipore Ltd., Cork, Ireland) that had been washed with 50 mL of ultrapure water. Before starting the experiments, filtered mAb solutions were temporarily stored in 50 mL falcon tubes (Thermo Fisher Scientific, Rochester, NY).

Stock solutions of PS20 and PS80 1% and 10% (w/w) were prepared by diluting the original solutions in ultrapure water and mixed using a vortex until homogenous. Since bubbles were generated during this mixing process, the mixed solution was allowed to rest until no bubbles were seen. These diluted surfactant solutions were wrapped in aluminum foil to prevent photodegradation and stored in a 4 °C refrigerator until further use.

The appropriate amount of surfactant stock solution was spiked into the 0.5 mg/mL mAb solutions to prepare mAb/surfactant formulations with a surfactant concentration of 100 ppm and 10 ppm. The prepared samples were gently inverted and left undisturbed (for at least 30 min) until used. The surfactant concentrations studied here were chosen to represent polysorbate concentrations that are above and below the critical micelle concentration (CMC) for both polysorbates. PS80, with more hydrophobic chains (mono-oleate vs. mono-laureate), has a lower CMC (13–17 ppm for PS80, vs. 60 ppm for PS20) [26, 27]. Typically, polysorbates are added in relatively small amounts (0.01 to 1 mg/mL) while still ensuring that they are above the CMC. Therefore, in this work, 100 ppm represents surfactant formulation above CMC. A lower surfactant concentration was also studied in this work to represent a lowering of surfactant concentration due to dilution or loss of material as a result of surfactant degradation.

Langmuir Dilatational Stress Studies

A Langmuir trough (LT) apparatus (Biolin Scientific, Inc., Stockholm, Sweden) was used to isolate dilatational stresses to the a/w interface of mAb formulations and monitor the interfacial properties. Our Langmuir trough holds 39 mL of solution and is equipped with two moveable Delrin barriers that can be used to apply stress only to the interface, by changing the barrier position. The trough has an interfacial area of 7750 mm2 when the barriers are fully expanded and an area of 1650 mm2 when the barriers are fully compressed. A Wilhelmy plate (filter paper, Whatman, GE Healthcare UK Limited, Little Chalfont, Buckinghamshire) attached to the LT allows monitoring changes in surface pressure (SP) of the sample of interest during the compression and expansion cycles. Prior to performing any experiments, the trough, the barriers, and all associated accessories were washed several times with acetone, isopropanol, and ultrapure water. After the washing steps were completed, the SP of a clean a/w interface was recorded as the barriers were compressed slowly to ensure that the SP was below 0.3 mN/m throughout.

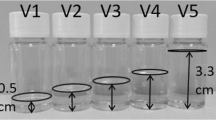

After cleaning the trough, the prepared mAb1 and mAb2 samples at 0.5 mg/mL formulated either with PS20 or PS80 were poured into the trough, and the evolution of the SP with time was recorded over the course of 2 h to allow proteins sufficient time to adsorb to the interface. After 2 h, the LT was programmed to compress the air–water interface with the Delrin barriers at a rate of 150 mm/min for 750 compression/expansion cycles lasting a total of 6 h. After the compression/expansion cycles, 8–10 mL of the solution was extracted from the sub-phase using a syringe and a 20G needle (Thermo Fisher Scientific, Rochester, NY) through a small port at the base of the trough that is parallel with the interface. Care was taken to ensure that the interfacial film was not disturbed. Then another syringe and 20G needle were used to aspirate 8–10 mL of material from the interface. Both the bulk and the interfacial material were transferred to 15 mL falcon tubes and stored at 4 °C in a refrigerator until further analysis. All experiments were run in triplicate and at a temperature of 23 ± 2 °C.

Microflow Imaging

A micro-flow imaging 5200 (MFI) (Protein Simple, San Jose, CA) instrument was used to quantify and characterize the size (2–100 µm equivalent circular diameter, ECD) morphology of any subvisible particulates generated during interfacial compression and expansion, as described previously [24, 28]. The flow cell was flushed with a cleaning cycle of filtered ultrapure water and 2.5% Liquinox solutions to ensure that the particle count was below 300 particles per mL when using ultrapure water; 0.6 mL of sample, at a flow rate of 0.17 mL/min, was used for each measurement. The results were processed and analyzed using MFI View Analysis Suite (MVAS) software (Protein Simple) and protein particle concentrations of equivalent circular diameter (ECD) and morphology were recorded. Based on our previous measurements of protein particle formation using MFI, all particles that had a circularity and an aspect ratio above 0.9 were excluded to remove any silicone oil droplets and air bubbles that were present in the samples [29,30,31]. Additionally, glass shards and rubber particles were also removed from the data sets. After these filters were applied to the data set, the results were visually confirmed to ensure that no mAb particles were removed after applying the filters. Since we have previously shown that application of interfacial stress causes an increase in the concentration of particles formed at the interface and in bulk solution, in this work, to conserve precious material, protein particles were measured only for the stressed condition [7, 24, 28].

Results

In this study, a LT and surface tensiometer was used to apply interfacial stress and observe the interfacial response of two different IgG mAbs (mAb1 and mAb2) that were formulated with either PS20 or PS80 both above and below their critical micelle concentration (CMC). The barriers of the Langmuir trough are configured such that their movement isolates the stress at the air–water interface for the sample of interest. Our previous work established that mAb1 is the more stable molecule while mAb2 is more prone to interfacial stress-induced particle formation [24]. The focus of this work was to present a comparison of the interfacial properties of the same IgG mAb when formulated with PS20 or PS80.

Surface Activity of mAb/Surfactant Solutions Formulated with PS20 or PS80 in the Absence of Applied Interfacial Dilatational Stress

The first step in assessing interfacial stress-induced protein particle formation (PPF) in mAb/surfactant solutions was to characterize the surface activity of the two IgG mAbs, formulated in PS20 or PS80, in the absence of any applied interfacial stress. The change in SP with time for mAb1 samples formulated with either PS20 or PS80 at 100 ppm are presented in Fig. 1. Figure 1A shows that in the absence of protein, both PS20 and PS80 reached a saturation value of SP almost immediately, although final value was higher for PS20 than PS80 (32.5 mN/m vs. 25 mN/m). Figure 1B demonstrates that when mAb1 was formulated with PS80 at 100 ppm(shown in mustard yellow), the kinetics of adsorption follows that in Fig. 1a for protein-free PS80 solutions. To contrast this with formulations that do not contain any surfactant, the SP of mAb1 solutions without surfactant is also shown (in blue). Our results show that the SP for mAb1 protein-only solutions reaches an equilibrium value of 14.8 mN/m at the 2-h point. In contrast, the equilibrium SP of mAb1-PS80 formulation is higher, reaching 25.4 mN/m and is similar to the PS80-only samples. Further, the maximum SP is reached much faster (~ 20 min) compared to mAb1-only samples.

When 100 ppm PS20 is introduced to the mAb1 formulation (shown in red), the SP also increases rapidly and achieves the highest equilibrium SP at 34.1 mN/m. Interestingly, the equilibrium SP for samples containing PS20 above the CMC took longer to achieve complete equilibrium as the evolution of the SP appears to go through a stage of small, slower growth.

Figure 1C shows the same interfacial analysis (SP vs. time) for a different IgG mAb (mAb2) that has been shown to be more prone to interfacial stress-induced particle formation. Our results show similar trends as observed in mAb1 samples, with both protein/surfactant formulations showing an initial rapid increase in SP. However, mAb2 samples formulated with 100 ppm PS20 demonstrated a higher equilibrium SP (35.1 mN/m) compared to mAb2 proteins formulated with PS80. Further, while mAb2 when formulated in PS80 rapidly reached a saturation value, the adsorption kinetics for mAb2 solutions formulated in PS20 showed a continuous increase.

Our next step was to monitor the SP evolution with time for mAb/surfactant solutions formulated with 10 ppm PS20 or PS80. Figure 2A presents control studies measuring the surface activity of both surfactants at 10 ppm without the protein. This result shows that surface activity of PS20 remains higher than PS80 even at this very low concentration. Figure 2B shows that samples of mAb1 formulated with 10 ppm PS80 (shown in gold) reach an equilibrium SP (17.5 mN/m) that is comparable to the mAb1 alone (blue curve) and is lower than the maximum SPs reached when formulated in 100 ppm PS80 (Fig. 1B). Our results also show that mAb1 formulations containing 10 ppm PS20 show a surface activity that is much lower than the 10 ppm PS20 alone control sample. Additionally, for mAb1 formulated in PS20, after 2 h adsorption (red curve), the SP did not reach an equilibrium value. Further, the SP reach is also significantly lower than the SP of mAb1/100 ppm PS20 solutions. Figure 2C shows surface activity evolution with time for mAb2 solutions formulated with 10 ppm PS80 (shown in gold) and 10 ppm PS20 (shown in red). Again, a similar trend is seen where the surface activity of both mAb2/surfactant solutions show an initial rapid increase in the SP. Further, mAb2 formulated in PS20 is found to show a higher maximum SP compared to mAb2/PS80 and mAb2 alone solutions.

Surface Activity of mAb/Surfactant Solutions Formulated with PS20 or PS80 When Subjected to Interfacial Dilatational Stress

Figure 3 presents the change in SP with change in interfacial area during the compression and expansion cycles for the two mAb samples containing either 100 ppm of PS20 or PS80. The 1st, 2nd, and 750th compression/expansion cycles are shown in blue, gold, and red, respectively. A few commonalities are seen in all samples. At the beginning of the 1st cycle, the SP corresponds to the equilibrium SP value that is achieved after 2 h of adsorption. Upon compression, the interfacial area decreases and the SP increases and reaches a maximum SP for all protein/surfactant solutions. Upon expansion, a decrease in the SP with increasing interfacial area is observed. Thus, the protein films demonstrate a lack of overlap (or hysteresis), which suggests irreversible intermolecular interactions between the protein molecules at the interface. Further, subsequent compression/expansion cycles result in a lower SP at the beginning of each compression cycle as the protein/surfactant samples do not have enough time to reach the saturation SP. The highest SP reached at the end of each compression is also found to decrease as a function of the compression/expansion cycles.

Comparison of the effect that dilatational interfacial stress has on mAb1 and mAb2 solutions formulated with 100 ppm PS20 and PS80 that were exposed to 750 cycles of interfacial compression and expansion in a Langmuir trough at a rate of 150 mm/min. Cycle 1 (blue), cycle 2 (orange), and cycle 750 (red). The isotherms are presented as representative. Three repeats were done

The leftmost panel shows the effect of interfacial compression and expansion on the surfactant controls. Comparing PS20 with PS80, our results show that while PS80 reaches a maximum SP of 35 mN/m at the lowest interfacial area, PS20 reaches a maximum SP of 45 mN/m. The middle panel shows the SP vs. area compression/expansion isotherms for mAb1/surfactant solutions. mAb1/PS80 solutions show a maximum SP at the end of the first, second, and 750th cycles, and all show a higher value compared to the PS80 control. In contrast, mAb1/PS20 isotherms are comparable to the PS20 control. There are also larger differences between the slope of the compression cycles for the 1st and 2nd cycles for mAb1 formulated with PS20 than for those observed in mAb1 and PS80 samples. The rightmost panel shows the SP vs. area isotherms for mAb2/surfactant solutions. The SP vs. area isotherms for mAb2/PS80 and mAb2/PS20 samples closely resemble those of samples containing only PS80 or PS20, respectively, including the maximum SP reached at the end of each compression cycle and the difference in the compression and expansion curves.

Figure 4 shows the 1st (shown in blue), 2nd (shown in gold), and 750th (shown in red) compression/expansion cycles for the mAbs formulated in 10 ppm PS20 and PS80. The left panel shows the SP vs. area isotherms for the PS80 (top) and PS20 (bottom) surfactant solutions. While both surfactants show an increase in SP with compression, PS80 isotherms show very little hysteresis during the compression/expansion cycle. The middle panel shows the SP vs. area isotherms for mAb1 formulated in PS80 (top) and PS20 (bottom). The isotherms show that the SP reach when the barriers are compressed to the minimum possible area is higher for the mAb1/PS80 solution when compared to the PS80 alone while the minimum SP reach at the end of the expansion cycle is lower than the PS80 sample. Further, the hysteresis (difference between the compression and expansion cycles) is also larger for the mAb1/PS80 solution compared to the PS80 controls. Interestingly, for mAb1 formulated in PS20, the isotherms resemble that of the PS20 alone, with only the minimum SP being lower than the PS20 controls. The panel on the right shows the SP vs. area isotherms for mAb2 formulated in PS80 and PS20. Here, for both formulations, the maximum SPs reached when compressed to the minimum area possible are higher and the minimum SPs reached when the area expands to the maximum possible area are lower than that measured for the surfactant only solutions.

Comparison of the effect that dilatational interfacial stress has on mAb1 and mAb2 solutions formulated with 10 ppm PS20 and PS80 that were exposed to 750 cycles of interfacial compression and expansion in a Langmuir trough at a rate of 150 mm/min. Cycle 1 (blue), cycle 2 (orange), and cycle 750 (red). The isotherms are presented as representative. Three repeats were done

Particle Formation of mAb Samples Formulated with PS20 or PS80

Figure 5 shows the particle morphology and size as heat maps for mAb1 (Fig. 5A) and mAb2 (Fig. 5B) formulated in 100 ppm of PS80 or PS20. The ECD of the particles is indicated by a heat map with the warm colors (red) corresponding to the smallest particles and cold colors corresponding to the largest (see key for exact ECD ranges). The data is plotted as a function of the circularity (defined as the perimeter of the particle relative to a circle that would have an equivalent area) of the particles and their aspect ratio (which corresponds to how elongated a specific particle is) [7, 32]. The circularity and the aspect ratio are constrained between 0 and 1 with the point (1, 1) in the plot corresponding to a perfect circle. The gray curve plotted in the mAb1-only dataset corresponds to the calculation reported by Kalonia et al. of the circularity of theoretical prolate ellipses from a specific aspect ratio [32]. Particles that deviate from the gray curve have a larger perimeter than that of an ellipse with the exact same area which indicates that the surface roughness has increased.

Aspect ratio (AR) versus circularity (C) heat maps depicting particle size (ECD) distribution for the protein mAb1 or mAb2 without any surfactant (control, top row), mAb1, or mAb2 formulated in 100 ppm PS80 (middle row), and mAb1/mAb2 formulated in 100 ppm PS20 (bottom row). mAb1 and mAb2 are at 0.5 mg/mL in PBS buffer at pH 7.6 with 100 ppm of both surfactants. MFI was obtained after a 2-h adsorption and 750 compression cycles at 150 mm/min. Heat maps are representative figures with N = 3. Control**: represents protein samples without surfactants that were previously published in Vaclaw et al. J. Pharm Sci, 110(2) 746–759, 2021

Figure 5A shows that there is a clear difference in the efficacy of PS20 vs. PS80 in mitigating the formation of larger aggregates especially when compared to particle formation of mAb1-only samples, which show formation of particles at the a/w interface. PS20 appears to be much more effective at preventing larger PPF with increased surface roughness in mAb1 samples, especially at the interface, although there does still appear to be smaller particles in the bulk solution. On the other hand, PS80 appears to mitigate the formation of large particles at the interface but exhibits PPF in the bulk solution.

Figure 5B shows that for mAb2/surfactant solutions, while both surfactants are able to mitigate PPF, samples containing PS80 resulted in larger, more elongated particles forming at the interface and in the bulk when compared to particle formation in samples containing PS20.

Figure 6 presents the morphology and particle size distribution of mAb samples formulated with 10 ppm PS20 or PS80. Figure 6A shows that while PS20 at lower concentrations is able to mitigate the formation of larger particles in the bulk solution, samples containing mAb1 and PS80 appear to still have a number of larger particles at the interface when compared to samples with only mAb1. Figure 6B shows that both surfactants are effective at preventing large particles from forming when compared to mAb2-only samples but show significant number of smaller particles even in the presence of surfactants, demonstrating that these lower surfactant concentrations are unable to mitigate formation of smaller particles.

Aspect ratio (AR) versus circularity (C) heat maps depicting particle size (ECD) distribution for the protein mAb1 or mAb2 without any surfactant (control, top row), mAb1, or mAb2 formulated in 10 ppm PS80 (middle row), mAb1/mAb2 formulated in 10 ppm PS20 (bottom row). mAb1 and mAb2 are at 0.5 mg/mL in PBS buffer at pH 7.6 with 100 ppm of both surfactants. MFI was obtained after a 2-h adsorption and 750 compression cycles at 150 mm/min. Heat maps are representative figures with N = 3. Control**: protein controls without surfactant were previously published in Vaclaw et al. J. Pharm Sci, 110(2) 746–759, 2021

In Fig. 7, we provide a comparison of the particle size distributions for > 10 and > 25 um for both mAbs formulated in 100 and 10 ppm of PS80 and PS20. Overall, the total number of particles formed in mAb2 solutions is orders of magnitude higher than in mAb1 solutions.

For mAb1 solutions, addition of the polysorbates does not show a reduction in the total number of particles formed in the bulk solution with a size > 10 μm. In fact, addition of 100 ppm PS20 causes an increase in the total number of particles formed at the air/water interface. Our results also show that all polysorbate formulations are able to reduce the total number of particles with size > 25 μm.

For mAb2 samples, the addition of both PS20 and PS80 is able to significantly lower the total number of particles > 10 μm when formulated at 100 ppm. However, mAb2 solutions containing 100 ppm of PS20 show less particle formation compared to solutions containing PS80. When evaluating particles with sizes greater than 25 μm, addition of 100 ppm PS20 is able to reduce the particle counts from 1000 to less than 10 particles/mL. However, 100 ppm PS80 is only able to reduce the particle count to 100 particles/mL.

Discussion

The main focus of the current work was to measure and analyze the interfacial properties of the same IgG mAbs that were formulated with either PS20 or PS80 and correlate that data to subvisible particle formation data measured by MFI. This comparison was done in order to better understand how the interfacial properties may influence interfacial-stress induced particle formation and examine the efficacy of the two different types of surfactants in preventing particle formation. The Langmuir trough technique has been used previously to apply compression/dilatational stress to mAb films at the air–water interface which simulates the changes in interfacial area that these formulations experience during agitation [7, 33]. Since the Langmuir trough technique is capable of isolating the applied stress to the air–water interface, the interfacial properties of the mAb films can be correlated to interface-induced protein particle formation.

Comparison of Surface Adsorption of mAb Solutions Formulated with PS20 or PS80

Initially, the SP was monitored in the absence of any stress to observe trends in adsorption kinetics and equilibrium SP value differences between the two surfactants with both mAb1 and mAb2. In the absence of proteins, the differences in the equilibrium SP values for PS20 vs. PS80 solutions likely arises due to differences in the fatty acid side chain distributions for each surfactant. PS80 is primarily composed of oleic acid, which has a longer hydrocarbon chain than lauric acid, which is the primary component of PS20 [34]. It has been previously shown that an increase in the fatty acid chain length leads to a higher value of surface tension or a lower value of surface pressure [35]. Therefore, it is possible that PS20, which has a higher content of lauric acid C (12:0), shows a higher surface pressure or lower surface tension value compared to PS80. Similar results were also reported by Garidel et al. in 2021 for PS20 and PS80 high-performance-grade materials [27].

In the absence of surfactants, both mAb solutions showed a much lower SP compared to the surfactant-only solutions. When considering the surface adsorption of mAb-only solutions, previous studies have shown that the SP changes may not necessarily correlate with mAb concentration at the interface [10, 36]. These studies observed that the surface excess of mAb, as measured by confocal microscopy, often equilibrates within 90 s of the measurement [22]. In contrast, our results show that while mAb1 solutions reach an equilibrium SP relatively quickly, mAb2 solutions do continue to show a small increase in SP. We and others have argued that the change in SP of mAb formulations with time may be a combination of mAb adsorbing onto the air–water interface and partial unfolding of the proteins at the interface [28].

The surface activities of both surfactants studied here are found to be higher than the two mAbs used in this study.This difference in kinetics is not surprising. In fact, the faster adsorption kinetics of PSs allow them to compete for the interface, prevent adsorption of proteins onto the a/w interface; therefore, they are ideal candidates to mitigate PPF at interfaces [14].

Next, it was found that when formulated at 100-ppm surfactant concentration, the adsorption isotherms of all mAb/surfactant solutions look similar to the surfactant-only solutions. This suggests that at concentrations higher than the critical micelle concentration (c.m.c), the interface is surfactant-dominated, i.e., the surfactants are able to compete and adsorb to the interface and prevent adsorption of the protein. However, at surfactant concentrations lower than the c.m.c, the maximum SP reached by mAb/surfactant solutions shows different behaviors for different surfactant/mAb mixtures. For mAb1/PS20 solutions, the equilibrium SP is never achieved and instead steadily increases over the course of the 2 h. This result indicates that at low surfactant concentrations (below the C.M.C.), there may be co-adsorption of the protein and the surfactant at the a/w interface for mAb1/PS20 mixtures. Similarly, for mAb2/surfactant mixtures, the surface pressure adsorption curves donot overlap with the surfactant-only curves, suggesting that both surfactants and proteins are present at the interface. This could be because at lower surfactant concentrations, the surface is not fully saturated with surfactant or because both molecules are able to compete for the interface. Kanthe et al. have previously shown that at sufficiently low surfactant concentrations, co-adsorption of the mAb and the surfactant dominates the composition of the molecules at the interface, whereas at sufficiently high surfactant concentrations, the surfactant molecules outcompete the mAbs for the air–water interface [23]. The authors also showed that differences in the surface activity of the mAbs determine the surfactant concentration needed to prevent mAb/surfactant co-adsorption, with proteins with lower surface activity requiring a lower surfactant concentration to outcompete proteins adsorbing to the interface. Our results also suggest that the amount of surfactant needed to prevent adsorption of the mAb to the a/w interface also depends on the concentration of molecules competing for the a/w interface. Even though PS20 shows more surface activity and a higher maximum SP compared to PS80, for mAbs formulated at concentrations lower than the c.m.c, PS20 have a lower tendency to compete with the proteins for the interface compared to the same concentration of PS80.

Comparison of Surface Activity of mAb Solutions Formulated with PS20 or PS80 Under Interfacial Dilatational Stress

The results of the studies monitoring the change in SP with application of interfacial dilatational stress show that when the mAbs with different surface activity and relative stability are formulated with surfactants PS20 and PS80 at concentrations above their c.m.c, the surfactant appears to dominate the interface and the isotherms largely resemble those of surfactant-only solutions, suggesting that the surfactants outcompete the mAbs from adsorbing to the interface. Further, the SP vs. trough area isotherms from Ab/surfactant solutions demonstrate hysteresis between the expansion and compression curves, similar to what has been reported before [7, 24, 33]. Hysteresis in these cycles indicates either an irreversible loss of material from the interface into the bulk solution or irreversible interactions between the molecules at the interface that ultimately lead to protein particle formation. Our results show that at high surfactant concentrations, the solutions have very little hysteresis, suggesting that the surface is possibly dominated by the surfactant even when subjected to interfacial stress. On the other hand, when the two mAbs are formulated at surfactant concentrations below the c.m.c, the isotherms have marked differences from surfactant-only or mAb-only solution isotherms but rather show signatures that are between the surfactant only or mAb-only solutions, suggesting co-adsorption of the protein and surfactant molecules to the interface. Both mAb1 and mAb2 formulated in 10 ppm PS80 show higher hysteresis between the compression and expansion isotherms, suggesting that in the event of co-adsorption of protein and surfactant to the air–water interface the protein competes with the surfactant to adsorb to the air–water interface as the interfacial area is continuously changed during compression/expansion cycles. On the other hand, when formulated in PS20, both mAbs show SP vs. area isotherms that are similar to the surfactant-only solution. This is in contrast with the static adsorption studies where we found that both mAb1 and mAb2 solutions formulated in 10 ppm PS20 led to co-adsorption of the protein and surfactant.

In summary, application of dilatational stress allows us to apply transient mechanical stresses to the interface alone without subjecting the bulk to any mechanical stresses. Given that the rate of surfactant and mAb adsorption shows differences in kinetics, an equilibrium is not reached between molecules in the bulk and at the interface. Therefore, application of dilatational stress at the interface impacts the competitive adsorption between the surfactant and the mAb molecules competing for any new area that is generated during the start of every expansion cycle. Our results show that in fact the rate of adsorption will ultimately determine the outcome of competitive adsorption between the surfactant and mAb molecules, when mAb/surfactant mixtures are subjected to interfacial dilatational stresses that have a direct relevance of mechanical agitation faced by therapeutic protein solutions (7, 32). PS20, which demonstrates the fastest rate of adsorption, dominates the interface when interfacial dilatational stresses are applied possibly because of the faster adsorption kinetics of the PS20 molecules.

Comparison of Protein Particle Formation Due to Application of Dilatational stress

The analysis of the interfacial properties of the mAb/surfactant air–water interface was complemented with particle characterization data to determine the efficacy of the surfactants in mitigating interfacial stress-induced PPF in mAb formulations. In a previous work [7], we described size exclusion chromatography (SEC) experiments that were done on the protein particles formed when the air–water interface was subjected to interfacial dilatational stress. We found that for this kind of stress, only 1% of the solution showed higher molecular weight species. Interestingly, we also found that the bulk protein retained its native state. Therefore, in the interest of conserving proteins, in this work, we only focused on the protein particle characterization using MFI. For both the mAbs studied here, we have previously shown increased PPF at the interface and in the bulk solution when the interface is subjected to dilatational stress at the interface using the Langmuir trough [24]. Therefore, in this work, we focused on the ability of PS20 and PS80 surfactants to prevent PPF after application of interfacial stress. Particle formation rates show that overall both surfactants mitigate the formation of larger particles (> 10 and > 25 μm) in the bulk solution. The data also conclusively shows that PS20 is much more effective at preventing the formation of these large particles for both mAb1 and mAb2 formulations. However, significant differences are seen when evaluating the formation of protein particles at the interface. For mAb2/surfactant solutions, both surfactants show a lowering of the number of particles formed at the interface compared to the surfactant free mAb2 solutions. On the other hand, for mAb1/surfactant solutions, an increase in protein particles is measured at the interface for 100 ppm PS20 solutions. This is counter-intuitive as the surfactant should be saturated at the interface, thereby protecting the mAb from adsorbing. One possibility is that the surfactants interact differently with the two proteins in bulk solution, with mAb1 forming surfactant/protein complexes in solution that are not formed with mAb2/surfactant mixtures. Using MFI alone, we cannot conclusively provide evidence of surfactant/mAb complex formation in bulk solution. However, an increase in PPF is not seen below the CMC, which does support the possible role of micelles in promoting protein particle formation. Further, even the possibility of formation of mAb/surfactant complexes is debated [16, 27]. Moreover, if indeed mAb surfactant micelle complexes are being formed, it is unclear why mAb1 would form these complexes but not mAb2.

Another possibility is that the differences in the adsorption rates of the mAb/surfactant mixtures in the different formulations ultimately dominate how many protein particles are formed at the interface and in bulk solution. Our compression/expansion results seem to support this hypothesis. Our results show that during application of dilatational stresses, PS20 always dominates at the interface. Therefore, for our systems, PS20 is better able to mitigate the formation of protein particles. For mAb1 formulated in PS80, our compression/expansion results show that proteins, and not PS80, dominate the interface when subjected to interfacial dilatational stresses. This reduces the ability of PS80 to prevent PPF in mAb1 solutions when subjected to interfacial dilatational stress.

Conclusions

In this work, we have analyzed the interfacial properties of two different IgG mAbs formulated with either PS20 or PS80 at the same concentrations. Additionally, we correlated these results with subvisible particle formation data sets obtained with MFI including rates, size distributions, and morphology. The goal is to better understand the efficacy of the two PS in protecting the two mAbs from interfacial stress-induced particle formation and to identify when interfacial parameters may be indicative of a mAb’s propensity to form particles when exposed to dilatational stress. Our results show that the SP vs. time kinetics and the SP vs. interfacial area isotherms can help identify which PS type performs better in mitigating particle formation during stress. The maximum and minimum SPs at each compression/expansion cycle as well as the hysteresis patterns observed in the SP isotherms are indicative of whether the surfactant dominates the interfacial properties of a formulation or if there is co-adsorption of the mAb and the surfactant at the air–water interface. Our SP measurements during static and compression/expansion studies show evidence of co-adsorption of protein and surfactant to the air–water interface for mAb/surfactant solutions. Specifically, we report that concentration of surfactant solutions as well as the mAb itself determines if the interface is dominated by mAbs or the surfactants. Further, we also report that for mAb2 (with higher tendency to undergo interface-induced protein particle formation), addition of PS20 is much more effective in preventing the formation of large particles both in the bulk and at the interface when compared to mAb2/PS80 formulations. On the other hand, for mAb1, with less tendency to form dilatational stress induced protein particles at the interface, both surfactants had similar ability to prevent formation of larger subvisible particles (> 25 µm). Thus, our results suggest that the choice of surfactant may also depend on the nature of the therapeutic protein, including its inherent tendency to form protein particles at the interface.

This work demonstrates the utility of interfacial techniques and interfacial stress analysis in evaluating the performance of surfactants in mitigating particle formation in mAb formulations. Future work will focus on characterizing other surfactant types and role of different surfactant grades as well as fatty acid content in protein particle formation with various mAbs. Additionally, future work will evaluate the effect that polysorbate degradation products such as free fatty acids have on the interfacial properties of mAb formulations. Finally, the authors believe that the pH, buffer content, and presence of different excipients will also impact the interactions of the surfactants with the mAbs, which in turn will impact the ability of the surfactants to prevent protein particle formation. These topics will be explored in the future.

References

Golan BL, Quentin JB, David E. Protein therapeutics: a summary and pharmacological classification. Nat Rev Drug Discovery. 2020;7(1):21–39.

Wu R-ML, et al. Development of therapeutic antibodies for the treatment of diseases. J Biomed Sci. 2020;27(1):1–30.

Lowe D et al., Aggregation, stability, and formulation of human antibody therapeutics, in Advances in Protein Chemistry and Structural Biology, R. Donev, Editor. 2011, Academic Press. p. 41–61.

Carpenter JF, et al. Overlooking subvisible particles in therapeutic protein products: gaps that may compromise product quality. J Pharm Sci. 2009;98(4):1201–5.

Sauna CY, et al. Pharmacogenetics and the immunogenicity of protein therapeutics. Nat Biotechnol. 2011;29(10):870–3.

(USP), U.S.P., <788> Particulate matter in injections. 2007.

Ghazvini S, et al. Evaluating the role of the air-solution interface on the mechanism of subvisible particle formation caused by mechanical agitation for an IgG1 mAb. J Pharm Sci. 2016;105(5):1643–56.

Li J, et al. Interfacial stress in the development of biologics: fundamental understanding, current practice, and future perspective. AAPS J. 2019;21(3):44.

Gerhardt A, et al. Surfactant effects on particle generation in antibody formulations in pre-filled syringes. J Pharm Sci. 2015;104(12):4056–64.

Kannan A, Shieh IC, Fuller GG. Linking aggregation and interfacial properties in monoclonal antibody-surfactant formulations. J Colloid Interface Sci. 2019;550:128–38.

Randolph TW and Jones LS, Surfactant-protein interactions, in Rational Design of Stable Protein Formulations: Theory and Practice, J.F. Carpenter and M.C. Manning, Editors. 2002, Springer US: Boston, MA. p. 159–175.

Thirumangalathu R, et al. Silicone oil- and agitation-induced aggregation of a monoclonal antibody in aqueous solution. J Pharm Sci. 2009;98(9):3167–81.

Kiese S, et al. Shaken, not stirred: mechanical stress testing of an IgG1 antibody. J Pharm Sci. 2008;97(10):4347–66.

Chou DK, et al. Effects of Tween 20 and Tween 80 on the stability of albutropin during agitation. J Pharm Sci. 2005;94(6):1368–81.

Nema S, Washkuhn RJ, Brendel RJ. Excipients and their use in injectable products. PDA J Pharm Sci Technol. 1997;51(4):166–71.

Lee HJ, et al. Molecular origins of surfactant-mediated stabilization of protein drugs. Adv Drug Deliv Rev. 2011;63(13):1160–71.

Wang S, et al. Stabilizing two IgG1 monoclonal antibodies by surfactants: balance between aggregation prevention and structure perturbation. Eur J Pharm Biopharm. 2017;114:263–77.

Deechongkit S, et al. Physical and biophysical effects of polysorbate 20 and 80 on darbepoetin alfa. J Pharm Sci. 2009;98(9):3200–17.

Petkov JT, et al. Dilatational and shear elasticity of gel-like protein layers on air/water interface. Langmuir. 2000;16(8):3703–11.

Courthaudon J-L, et al. Competitive adsorption of β-lactoglobulin + Tween 20 at the oil-water interface. Colloids Surf. 1991;56:293–300.

Liu L, et al. The effects of excipients on protein aggregation during agitation: an interfacial shear rheology study. J Pharm Sci. 2013;102(8):2460–70.

Begum F, Amin S. Investigating the Influence of polysorbate 20/80 and polaxomer p188 on the surface & interfacial properties of bovine serum albumin and lysozyme. Pharm Res. 2019;36(7):1–11.

Kanthe AD, et al. Armoring the interface with surfactants to prevent the adsorption of monoclonal antibodies. ACS Appl Mater Interfaces. 2020;12(8):9977–88.

Vaclaw C, et al. Impact of polysorbate 80 grade on the interfacial properties and interfacial stress induced subvisible particle formation in monoclonal antibodies. J Pharm Sci. 2021;110(2):746–59.

Mehta SB, et al. Gelation of a monoclonal antibody at the silicone oil–water interface and subsequent rupture of the interfacial gel results in aggregation and particle formation. J Pharm Sci. 2015;104(4):1282–90.

Mittal KL. Determination of CMC of polysorbate 20 in aqueous solution by surface tension method. J Pharm Sci. 1972;61(8):1334–5.

Garidel P, et al. Surface Tension and self-association properties of aqueous polysorbate 20 HP and 80 HP solutions: insights into protein stabilization mechanisms. J Pharm Innov. 2021;16:726–34.

Griffin VP, et al. Evaluating the combined impact of temperature and application of interfacial dilatational stresses on surface-mediated protein particle formation in monoclonal antibody formulations. J Pharm Sci. 2022;111(3):680–9.

Sharma DK, et al. Micro-flow imaging: flow microscopy applied to sub-visible particulate analysis in protein formulations. AAPS J. 2010;12(3):455–64.

Akhunzada ZS, et al. Separation, characterization and discriminant analysis of subvisible particles in biologics formulations. Curr Pharm Biotechnol. 2019;20(3):232–44.

Strehl R, et al. Discrimination between silicone oil droplets and protein aggregates in biopharmaceuticals: a novel multiparametric image filter for sub-visible particles in microflow imaging analysis. Pharm Res. 2012;29(2):594–602.

Kalonia C, et al. Calculating the mass of subvisible protein particles with improved accuracy using microflow imaging data. J Pharm Sci. 2015;104(2):536–47.

Bee JS, et al. Production of particles of therapeutic proteins at the air–water interface during compression/dilation cycles. Soft Matter. 2012;8(40):10329–35.

Kerwin BA. Polysorbates 20 and 80 used in the formulation of protein biotherapeutics: structure and degradation pathways. J Pharm Sci. 2008;97(8):2924–35.

Chumpitaz LDA, Coutinho LF, Meirelles JA. Surface tension of fatty acids and triglycerides. JAOCS. 1999;76:379–82.

Leiske DL, Shieh IC, Tse ML. A method to measure protein unfolding at an air-liquid interface. Langmuir. 2016;32(39):9930–7.

Acknowledgements

The authors thank Drs. Zhihua Lui, Dilbir Bindra, Mehrnaz Khossravi, Thiago Carvalho, and Mark Bolgar for helpful discussions.

Funding

This project was funded by an industry grant made for the University of Kansas by Bristol-Myers Squibb.

Author information

Authors and Affiliations

Contributions

PD, MG, and MOO conceived the idea and overall design of experiments for this collaborative work. CV, KM, and PD designed the detailed execution of the experimental design. CV, KM, and VPG performed the experiments. ND and DBV provided training and input on performing MFI experiments and associated data analysis. CV, KM, and PD wrote the first draft of the paper. All authors participated in the editing of the paper to its final form and providing responses to reviewer comments.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vaclaw, C., Merritt, K., Griffin, V.P. et al. Comparison of Protein Particle Formation in IgG1 mAbs Formulated with PS20 Vs. PS80 When Subjected to Interfacial Dilatational Stress. AAPS PharmSciTech 24, 104 (2023). https://doi.org/10.1208/s12249-023-02561-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-023-02561-4