Abstract

The human operator is acknowledged as the greatest potential source of contamination in aseptic processing. To avoid contamination, barrier systems have progressively reduced the amount of human intervention in the critical zone. This study extends the trajectory of enhanced patient safety through the elimination of human intervention in aseptic filling. Eight companies that are users of closed robotic workcells have aggregated their usage data from 2018 to 2021. The study analyzes the critical design elements and performance of the Cytiva SA25 Aseptic Filling Workcell. The SA25 is a standardized, fully closed robotic system for aseptic filling of vials, syringes, and cartridges that eliminates operator intervention in the critical zone. The standardized design means that the system is not modified to suit a particular application and the same environmental monitoring strategy can be used across different installations. The SA25 provides significantly increased sterility assurance when producing sterile injectables. Users have observed non-viable particle levels well within ISO 5/Grade A air requirements, with extremely low probabilities of entering a dosage container. There have been zero cases of microbial growth in more than 250 media fills and good manufacturing practice (GMP) batches. Across all dosage formats and sizes, the aseptic process is repeatable, with more than 99.3% of units meeting acceptance criteria. These data demonstrate that eliminating risk through design is successful in the SA25, with an improved aseptic process in comparison to filling systems using Restricted Access Barrier Systems (RABS) or isolators with glove ports. One of the contributing companies to this article achieved an industry first. The U.S. FDA-approved commercial production of their biologic drugs without the requirement for routine viable environmental monitoring (EM), requiring viable EM only during process simulations. Based on the data presented and planned future research, new regulatory consideration should be made for closed robotic workcells to ensure that regulations meant for previous technologies with different risk profiles are not inappropriately applied.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The human operator is accepted as the primary source of microbial contamination in the cleanroom due to their inherent microbial microflora [1, 2]. Cleanrooms populated with operators heavily influenced the need for EM in the aseptic space. EM has traditionally been used to monitor cleanrooms and indicate the general state of microbial control in the manufacturing environment. Cleanroom design and control has evolved since the 1960s with harmonization of standards and new classifications [3].

The introduction of isolator technology and barrier systems in the 1980s meant that the operator became more restricted in their involvement in the aseptic process. These systems promised a new era in aseptic processing that would result in the complete elimination of the operator from the aseptic processing area, and therefore significantly reduced microbial environmental monitoring and faster facility start-up [4]. Automated vapor-phase hydrogen peroxide (VPHP) decontamination cycle capability provides a 6-log10 reduction of spores.

Currently, the accepted isolator design allows the operator to manipulate the critical aseptic process through glove ports, which allows the successful operation of automated systems. Regulatory bodies have accepted that automated, decontaminated isolator technology can offer superior patient safety and should be considered for aseptic processing [5, 6].

The following study extends the trajectory of enhanced patient safety through elimination of human intervention in aseptic filling.

The SA25 Aseptic Filling Workcell is a standardized, completely closed, robotic isolator. The workcell is designed for the small-scale aseptic filling of multi-product, multi-container-format clinical, and commercial drug products. Large-scale commercial filling is supported by the scale out of identical standardized aseptic filling systems. Eight of the independent companies operating the SA25 provided their environmental monitoring and performance data. This study presents the SA25’s critical design elements, and it compiles end-user data to demonstrate that a closed robotic isolator, such as the SA25 Aseptic Filling Workcell, offers significantly increased sterility assurance when producing parenteral therapeutics.

SA25 Aseptic Filling Workcell Design

Many concepts for the SA25 come from the semiconductor industry where standardized closed robotic systems are commonly used to achieve conditions significantly more stringent than the pharmaceutical industry regarding particle generation. The term gloveless isolator and closed workcell are used to accurately describe these technologies. This paper will use both terms.

Notably, the control strategy is divided into two key segments: first, to provide an isolated environment with exceedingly low risk of transmission of viable or non-viable particulate to the primary container system through engineering controls; second, to use pre-sterilized primary containers in sealed packaging to provide sterility and particulate control. This strategy allows continuous improvement over time through sharing of operational data from users to both the machine manufacturer and vendors providing primary packaging (Table I).

Key hazard pathways, which are intrinsic in traditional filling lines, were identified for elimination through design and engineering controls. These hazards included:

-

Operator interventions into the critical zone and product pathway

-

Viable and non-viable contamination via direct and indirect product contact with the filling machine mechanical parts

-

Contamination caused by glove port leaks

-

Risk of particulate propagation via mechanical degradation of containers and closures caused by filling machine handling and movement

-

Contamination related to introduction of primary container components to the Grade A zone

-

Particulate contamination related to metal forming of aluminum crimp caps in the Grade A zone

The simplified interior design features facilitate first air principles by removing all viable contamination sources upstream of the critical fill location [6, 7]. A semiconductor-grade, hermetically sealed robot that can be fully decontaminated, is the only moving part upstream of the critical location where filling occurs. This robot was chosen to minimize the possibility of the robot shedding particles during operation. Airflow within the system is horizontal from the inlet HEPA filter towards the filling station and then continues toward the Decontamination and Staging Isolator (DSI) interface, where the air is removed through return HEPA filters.

There are three primary zones in the filling isolator and shown in Fig. 1. The supply zone, Zone 1, starts at the supply diffuser and includes the volume of space up to the fill pedestal. Zone 2 includes a volumetric strip where aseptic operations are performed. The final zone, Zone 3, is proximal to the DSI where tub opening operations are performed. The tub opening operation occurs in front of the return HEPA filter near the viable EM alpha port. This is considered the worst-case location for viable EM due to its location downstream of critical open processing in unidirectional, horizontal airflow. The horizontal airflow pattern was established to preclude movement of any particulate generated during tub opening to back flow from Zone 3 to Zone 2 as all operations are within the isolated environment (Fig. 2).

The simple mechanical design of system assemblies, and the isolator around them, has implications for decontamination system effectiveness and viable/non-viable particle monitoring. The isolator and tooling are designed with a minimum of polymeric/elastomeric components and are overwhelmingly comprised of passivated 316-L stainless steel and glass.

The SA25 is decontaminated with VPHP. Decontamination is defined as the overall process of removal of viable bioburden [5]. Typically, a 4- to 6-log10 reduction of viable resistant spores of Geobacillus stearothermophilis is deemed sufficient for decontamination of interior isolator surfaces. Temperature and relative humidity are monitored through the entire process. The decontamination process only starts when temperature and relative humidity parameters are within an acceptable range.

The system can decontaminate multiple cycle loads and aerate VPHP levels to 1 part per million (ppm) as determined by the Operator Exposure Limit (OEL) requirement, or to lower set-points as determined by product sensitivity to oxidation.

Continuous non-viable particle (NVP) monitoring, placed in direct proximity to the critical process area, within 1 ft as per regulatory guidance [5], provides valuable information on the state of the upstream aseptic environment continuously throughout the batch. A laser diffraction particle sensor for continuous non-viable particle monitoring, with integration of alarming and data collection, is the standard NVP collection device inside the SA25. The instrument measures the number of ≥ 0.5 µm and ≥ 5 µm particles per m3 using a rolling count, is oriented in the direction of the airflow, and performs isokinetic sampling with a 1 CFM flow rate.

Active microbial air sampling is performed with the RCS system, a device that uses centrifugal air impaction on agar strips, with a magnetically coupled impeller blade that is housed in a rapid transfer port (RTP) beta canister. The RTP is located such that the sampler draws immediately downstream of the zone where the containers are open and filling occurs. Sampling occurs during processing, with sample frequency determined based on the duration of production and on input from user’s risk assessment. No passive monitoring is performed, as the low deposition rate of particles smaller than 5 µm makes settle plates unsuited to this application [8].

Surface monitoring of the filling needle can be performed once at the end of production using EM swab sampling. The sampling method is automated and performed by the filling robot; thus, human intervention is not necessary. Following the sampling, the swab assembly is resealed, and then transferred to the microbiology laboratory for testing.

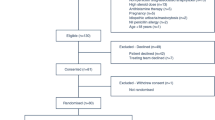

Materials and Methods

The companies participating in this study compiled and aggregated data from aseptic process simulations (media fills), clinical and commercial drug product manufacturing between 2018 and 2021 using their standardized SA25 Aseptic Filling Workcells. These machines are commercial, off-the-shelf systems, that are the same for all users. They have identical aseptic processes and are installed in similar cleanroom environments. Their production data reviewed in this study demonstrate that the SA25 Aseptic Filling machines provide operating performance and environmental conditions that are not only equivalent across multiple install locations but are also superior to conventional isolator technology. This significant increase in performance is easier to achieve with a standardized design.

Factors such as batch duration, container types, and the number of containers filled were collected from the data historian embedded in each machine’s control system. To evaluate the effectiveness of the design of the closed robotic isolator in environmental monitoring and process control, these key metrics were chosen:

-

Non-viable particle counts during production at 0.5 µm and 5 µm.

-

Viable particle detections using an RCS® Microbial Air Sampling system and post-fill needle swab.

-

Percentage of units produced that meet process parameters set by the system’s recipe-driven automation system and captured by the data historian.

Results

Computational Fluid Dynamics Modeling

Computational fluid dynamics (CFD) analysis was performed to understand the horizontal air flow behavior inside the SA25’s filling isolator. The objective of this analysis was to generate velocity contour and streamline plots that characterize air flow inside the chamber. The studies aim to further support the low disposition rate of small particles by demonstrating that small particles follow streamlines and have a very small probability of entering containers.

The studies were performed using the ANSYS Fluent v2109R2 CFD software and 132 CPU of high-performance computing. Modeling and meshing of the complete isolator used 25 million mesh elements.

Figure 3 demonstrates that at the velocities studied, air contours from the inlet filter follow a general horizontal, unidirectional pattern across the fill chamber encountering minimal objects before proceeding over the critical filling operation towards the DSI, exiting through the two exhaust filters on either side of a transfer door. Air from the fill chamber enters the Stoppering Vacuum Chamber (SVC) when the door opens but the air is not unidirectional.

The objective of Fig. 4 was to study the particle movement inside the chamber with a focus on vials on the fill station with an assumed release area based on robot seal movement. Failure of the filling robot’s seal is considered a risk to the process. If the air flow is inadequate, particles have the potential to enter vials on the fill pedestal. The particle sizes analyzed were 0.5 µm and 5 µm with a particle density of 2000 kg/m3. Discrete phase model (DPM) was used to model and track the path of particles. The streamlines shown in Fig. 4 demonstrates that particles of < 5 µm, if released from the assumed particle release area, will be swept away and will not settle on critical surfaces, further invalidating the use of settle plates.

Non-Viable Particle Data

Participants provided total non-viable particle data for 260 batches ranging from 1–142 h of total processing time. Data provided include multiple loads of material and excludes time periods for decontamination. The NVP data supplied were determined to have a non-normal distribution. A Poisson distribution was used to assess the 0.5 µm and 5 µm counts to predict the probability of out of specification events occurring (Figs. 5 and 6). The confidence intervals were approximated using chi squared critical values for non-normal distributions (Table II).

Viable Monitoring

Out of the 260 data sets provided by participants, 242 batches used the RCS and all samples resulted in no growth. One participant (18 batches) discontinued the use of active microbial air monitoring after they received regulatory approval by demonstrating that the system could be validated to control the aseptic environment. Of these 260 batches, 163 batches performed a post-fill needle swab, and from these samples, there were no positives. Eighty-seven batches did not use the swab because some of the system users use an alternative method to monitor the fill needle post-use (Table III).

Media Fills

Out of the 260 data sets provided by participants, 52 (20%) were identified as media fill batches. All media fills were completed successfully with a 0% failure rate, totalling 184,565 units. Media fill batch sizes ranged from 1800 units to greater than 12,000 units. All RCS and swab samples resulted in no growth.

Container sizes qualified included ISO 2R, 6R, 8R, 10R, 15R, and 50R vials; 1-mL and 10-mL syringes; and 1.5-mL cartridges (Table IV). Processing time, excluding decontamination cycle time, ranged from 1–143 h.

Pre-sterilized containers and closures of different sizes are nested with similar orientations and dimensions regardless of their size. For example, 6-15R vials are packaged identically, with the lone differentiator being their height. This is true for most nested components provided they come from the same manufacturer. The data do not reflect all container formats qualified, since they come from a “family” of similar containers. This means that qualifying a 6R vial is also representative of 8R, 10R, and 15R vials.

Machine Rejection Rates from Aseptic Filling Process

One of the key quality concerns of pharmaceutical manufacturing is whether dosages meet batch release criteria. Participating companies in this study made their data available for how many units out of the total produced met the process parameters set in the robotic isolator’s automation system (Table V). These data cover 260 production batches and are used to demonstrate that the process controls put in place with the SA25’s design create conditions where dosages are assuredly sterile and can carry out the process repeatably.

In the ten different filled dosage formats, the weighted median acceptance rate was 99.3%.

The comparatively low 91% acceptance rate for a 1.5-mL cartridge production was explained by the contributing company as caused by an isolator breach event during their aseptic process simulation. An isolator breach is the standard procedure when a situation occurs that cannot be recovered from via robotic interactions. The fill needle was resheathed prior to the breach of the isolator to maintain its sterility. During the breach, there are a maximum of two nests of filled containers that can be exposed to non-aseptic conditions. In this specific case, those two rejected nests (200 units total) resulted in the relatively low acceptance rate. After the breach was completed, the isolator was cleaned and decontaminated before continuing the fill. No positives media fill units were observed as a result of the breach, as shown in Table III.

Managing Risk in Aseptic Filling

U.S. FDA inspector Hank Avallone summarized the problem well.

“It is useful to assume that the operator is always contaminated while operating in the aseptic area. If the procedures are viewed from this perspective, those practices which are exposing the product to contamination are more easily identified.”[9].

Over 15 years ago, James Agalloco and Jim Akers remarked that “present technology does not allow us to measure microbial levels accurately in an aseptic environment.”[10]. Since that statement, developments in rapid environmental monitoring have not been widely validated in GMP environments. The current EM approach is a combination of active and passive air monitoring, surface sampling, and personnel sampling, which can be subject to contamination that is extraneous to the environment being sampled.

While these existing techniques offer some benefit in an environment that contains people, there is limited scientific justification to perform EM in an environment which removes the operator and is validated to maintain a safe environment for drug product.

A contamination control strategy is derived after a risk assessment is performed and the effectiveness of the control strategy is monitored over time. Invariably, the risk assessment will identify the presence of operators as a critical risk factor, and control strategies are designed around this. To this point, “the ‘”perfect” intervention is one that you do not have to perform.”[8]. The calculations and real-world examples from the Akers-Agalloco risk assessment method were used to perform an assessment for this article to demonstrate the comparative risk of different barrier types [10]. In following the revised Akers-Agalloco method, the aseptic compounding and lyophilization components were omitted for the purposes of this exercise because the SA25 does not carry out these activities [11]. The SA25 scored an order of magnitude lower than other accepted advanced filling technologies (Fig. 7).

The fundamental question becomes which controls and types of monitoring become appropriate. Continuous monitoring of additional areas would require more ports for sampling, creating additional potential failure points. Traditional methods require some form of human handling with the potential to add contamination risk to the process. It is already understood that exclusive monitoring or testing does not give assurance of sterility [5].

The critical failure modes for the SA25 are not unique and they are controlled and monitored. For example:

-

Isolator leak may compromise batch integrity and is controlled through standard chamber leak testing for all chambers prior to decontamination.

-

The SA25 is maintained at positive differential pressure during operation. The Filling Isolator is kept positive to the DSI. Typical operating differential pressures are 40 Pa for the Filling Isolator and 30 Pa for the DSI.

-

Loss of positive pressure is monitored throughout critical operations by separate differential pressure transducers in each of the isolator chambers, the DSI and the FI. Both transducers are monitored in real time. Air cleanliness is monitored in real time during critical processing using continuous NVP counter.

-

VPHP efficacy is controlled by providing a buffer to ensure a margin of extra kill.

-

Faults that stop the process and alert the operator during critical process that action is required.

What is unique to the SA25 is the removal and limitation of critical failure modes that exist on other closed isolator designs.

-

Removal of leaks in glove material that may compromise batch integrity.

-

Removal of defects in materials due to material handling and vial-to-vial contact.

-

Elimination of indirect product contact surfaces associated with material handling.

-

Elimination of aseptic set-up using pre-sterilized, ready-to-use flow path that remains closed until the isolator is sealed and decontaminated.

-

Elimination of aseptic interventions by operators.

Discussion

The data show that the environment of a completely closed workcell (with robotic material handling, filling, and closing operations), offers superior product protection by entirely separating the critical zone from the background environment. Elimination of direct human interventions and the reduced design complexity facilitates increased product sterility assurance and lower risk management requirements.

ISO 5/Grade A or better conditions are consistently met inside the critical filling chamber of the SA25. Normal operations typically see zero particle counts for the entirety of a batch. Low particle levels are achievable when personnel and complex mechanical operations are removed, allowing the environment to be maintained at acceptable cleanliness levels. The particle sizes monitored follow the unidirectional airflow pattern and are removed by the ventilation system [12]. Quality by design ensure a decrease of total particulate levels and reduces the need for contamination control through airflow.

The SA25 utilizes the industry standard of general unidirectional airstreams over critical open operations (as shown in Fig. 3). Other airflows are acceptable providing ISO 5/Grade A conditions are met and adequate protection for the exposed product is demonstrated [5, 6]. Non-unidirectional airflow in the Stoppering Vacuum Chamber is deemed acceptable based on assessment of risk and qualification studies that demonstrate ISO 5/Grade A conditions are maintained. These qualification studies are not included in the scope of this document but have been provided by participants to regulators during inspections.

A representative of U.S. FDA’s Center for Drug Evaluation and Research (CDER) said in a 2020 presentation that some of the aseptic processing challenges associated with expedited programs “may be alleviated by adopting advanced technologies involving the use of automated/robotic equipment in simplified facilities.” Automated gloveless isolators which include the SA25 can “eliminate direct human interactions with the product and support sterility assurance.” [13].

Removal of human intervention in the critical zone is fundamental to contamination control. Imposing sampling strategies to monitor a risk that has been engineered out of the process diminishes the benefits of closed robotic workcells. The effectiveness of current EM strategies is incapable of providing confidence regarding contamination risk. CFD data show that EM through the use of settling plates is not suitable for the design of the SA25 [12]. Operator “interactions” replace the unsafe aseptic interventions performed on conventional lines. This term was coined by end-users—the interactions are classed as routine or non-routine and are challenged during media fill. Routine interactions include active air sampling and material unloading and reloading. Non-routine interactions include cycle or emergency stops, holding open product in the isolator, or manual tooling movement from the HMI. An isolator breach is a standard procedure and can also be modeled as routine or non-routine breaches. A routine breach is performed while no product is exposed, i.e., no open containers or exposed fill needle, usually at the end of a load. A non-routine breach is to remedy a failure mode that cannot be addressed from the HMI. Such events are rare and only one such event is included in the data, experienced during the 1.5-mL cartridge media fill. Product loss is mitigated through resheathing the fill needle prior to the breach and process design which limits the number of containers exposed at one time to two nests. Re-decontamination of the chamber is required after the event before resuming the batch.

As with current closed systems, the SA25 requires decontamination prior to use. Common VPHP decontamination methods have proven successful. A cycle based on actual bioburden may be favored over one in which a worst-case bioburden load is assumed, as the cycle time will be reduced, ensuring decreased time for hydrogen peroxide adsorption [14, 15]. Risk management and process control present a different picture. Where other approaches allow for the introduction of contamination (which require interventions to manage it), the SA25 will eliminate the source of contamination. An ongoing state of control may be confirmed through real-time monitoring of pressure and particulate load within the chamber.

One needs to consider how a batch is to be released when using a closed robotic workcell. One alternative approach is to use the principles of parametric release. For product sterilized by moist heat, in lieu of sterility testing, the batch is released if defined critical process control parameters has been met. A similar method may be applicable to those products filled on a closed robotic workcell. Batches are released without viable EM if all critical process controls are met, and a pre-assessment of the environment has determined adequate control is maintained.

Closed robotic isolators are now in use on four continents with more than 35 installations at the time of writing. The U.S. FDA, Health Canada, and PIC/S have issued approvals for commercial products manufactured with these systems.

One of the contributing companies to this article achieved an industry first. The U.S. FDA-approved commercial production of their biologic drugs without the requirement for routine viable EM. The company was able to demonstrate, to the satisfaction of the regulators, that routine cultivation-based EM during product fills would not provide evidence that the environment was maintained in a state of control. In fact, it would add complexity and thus risk to an advanced aseptic process.

Rather than traditional EM, the emphasis was on system validation demonstrated through the following:

-

Efficiency and robustness of the automated VPHP cycles

-

Use of pre-sterilized single-use flow paths

-

Use of pre-sterilized nested vials and press-fit closures

-

The risk of contamination entering the aseptic process in a closed isolator

Conclusions

Based on the data presented and planned future research, new regulatory consideration should be made for closed robotic workcells to ensure that regulations meant for previous technologies with different risk profiles are not inappropriately applied. In other words, the conventional approach for monitoring the critical zone in traditional aseptic filling systems, i.e., the typical EM program, should not be applied to unconventional aseptic filling systems. Closed workcells are fundamentally different than traditional filling models and pose distinctive risk profiles for which conventional monitoring schemes are unsuitable. This article outlines that the SA25 was designed in accordance with the principles of Quality Risk Management (QRM) and the compiled data demonstrates that the environmental control strategies ensure that microbial, particulate, and pyrogen contamination is prevented in the final product. This meets the intent of the FDA and EMA guidelines for the manufacture of sterile products [5, 6].

The eight participating companies represent some of the longer-term end-users of the SA25 Aseptic Filling Workcell, and as more companies reach GMP operational status this data set will expand and be submitted for future publication. Based on these systems being standardized, off-the-shelf machines, these systems provide a high level of comparability.

The conclusions of the data generated by research can be summarized as follows:

-

That the design of a closed robotic isolator with automated decontamination is a robust aseptic environment free from microbial contamination, shown by 100% of media fills reporting no positive units

-

That the design of the closed robotic isolator is effective at lowering the risk of introducing particles into drug products by removing several sources of potential contamination, including operator intervention

-

That the design of the aseptic process creates conditions where dosages in different formats are acceptable for release in more than 99.3% of units produced (Table V)

To minimize risk and increase benefit, new aseptic filling technologies need new environmental monitoring strategies. Strategies should be based on controlling and monitoring critical process parameters with significantly reduced or no viable EM for batch release. The use of standardized products and collaboration of end-users has enabled us to provide critical information on the decreased risk, increased product safety, and increased patient safety that closed robotic isolators offer.

The design strategy of the SA25 Aseptic Filling Workcell is to progressively eliminate risk to the aseptic process through design, and not to merely mitigate or control risk. Closed robotic isolator technologies and decontamination processes have significantly improved aseptic processes compared to the filling systems of the past. The control strategy employed allows continuous improvement over time to an already robust capability.

Based on the data presented in this article, we are ready to engage with regulators and the wider industry to provide education on closed workcell technology. Additional studies are planned to further examine these systems, and the data set presented in this article will be updated as more members of our user group progress to GMP operations. The goal of this industry-vendor collaboration is to continuously decrease risk to patient and to set a new standard in performance through sharing of best practice, performance data, and challenge studies.

Data Availability

The datasets generated during and/or analyzed during the current study are not publicly available due to confidentiality reasons.

Change history

30 August 2022

A Correction to this paper has been published: https://doi.org/10.1208/s12249-022-02398-3

Abbreviations

- GMP:

-

Good manufacturing practice

- RABS:

-

Restricted access barrier systems

- EM:

-

Environmental monitoring

- VPHP:

-

Vapor-phase hydrogen peroxide

- HEPA:

-

High-efficiency particulate air

- DSI:

-

Decontamination and staging isolator

- ppm:

-

Part per million

- OEL:

-

Operator exposure limit

- NVP:

-

Non-viable particle

- RTP:

-

Rapid transfer port

- CFD:

-

Computational fluid dynamics

- SVC:

-

Stoppering vacuum chamber

- DPM:

-

Discrete phase model

- FI:

-

Filling isolator

- CDER:

-

Center for Drug Evaluation and Research

References

Sandle T. A review of cleanroom microflora: types, trends, and patterns. PDA J Pharm Sci Technol. 2011 Jul 1;65(4):392–403. https://doi.org/10.5731/pdajpst.2011.00765.

Vidali S. Human contamination control in a clean room. Microchem J. 1992 Jun;45(3):336–42. https://doi.org/10.1016/0026-265x(92)90093-I.

Sandle T. The development of cleanrooms: an historical review–Part 2– The path towards international harmonisation. Editor’s welcome. 2017:28.

Agalloco J. Opportunities and obstacles in the implementation of barrier technology. PDA J Pharm Sci Technol. 1995 Sep 1;49(5):244–8.

U.S. Food and Drug Administration. Guidance for industry: sterile drug products produced by aseptic processing – current good manufacturing practice. FDA; 2004.

European Commission. Annex 1: manufacture of sterile medicinal products. EC; 2020 Draft.

United States Pharmacopeial Convention. USP general chapter <797> Pharmaceutical compounding – Sterile preparations. USP; 2008.

Agalloco J, Akers J. Revisiting interventions in aseptic processing. Pharm Technol. 2011 Apr 1;35(4):69–72.

Avallone H. Current regulatory issues regarding parenteral inspections. J Parenter Sci Technol. 1989;43(1):3–7.

Agalloco J, Akers J. The simplified Akers-Agalloco method for aseptic processing risk analysis. Pharm Technol. 2006 Jul 1;30(7):60–76.

Agalloco JP, Akers J. A revised aseptic risk assessment and mitigation methodology. Pharm Technol. 2017 Nov;2(41):32–9.

Whyte W, Agricola K. Comparison of the loss of macroparticles and MCPs in cleanrooms by surface deposition and mechanical ventilation. Clean Air and Containment Review. 2018 Jul/Aug;35:4–10.

Hughes P. Expedited programs: phase appropriate regulatory expectations for microbial control and sterility assurance. 2020. https://www.casss.org/docs/default-source/cmc-strategy-forum-north-america/2020-cmc-na-speaker-presentations/speaker-presentation-hughes-patricia-cder-fda-2020.pdf?sfvrsn=298ed85e_4. Accessed 25 Mar 2021.

International Organization for Standardization. ISO 11137–2:2012. Sterilization of health care products – Radiation – Part 2: Establishing the sterilization dose. ISO; 2012.

International Organization for Standardization. ISO 11137–1:2006. Sterilization of health care products – Radiation – Part 1: Requirements for development, validation and routine control of a sterilization process for medical devices. ISO; 2006.

Acknowledgements

The authors of this paper would like to thank the membership of the Cytiva Workcell User Group for their ideas and contributions that helped move this research and resulting publication forward.

Author information

Authors and Affiliations

Contributions

JM, NB, KG, CK, AK, YL, TP, and TP made substantial contributions to the data acquisition as well as the content of this manuscript. AB also made substantial contributions to the content of this manuscript. All authors contributed to the review and revision of the content of this manuscript for important intellectual content. The authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

AB is an employee of Cytiva. The other authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original article has been corrected to update the presentation of author’s name from Aine Brennan to Áine Brennan with the fada over the "A", and to move reference to Table II from page 4 to page 6

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

McCall, J., Barnard, N., Gadient, K. et al. Environmental Monitoring for Closed Robotic Workcells Used in Aseptic Processing: Data to Support Advanced Environmental Monitoring Strategies. AAPS PharmSciTech 23, 215 (2022). https://doi.org/10.1208/s12249-022-02360-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-022-02360-3