Abstract

Continuous manufacturing (CM) is an emerging technology which can improve pharmaceutical manufacturing and reduce drug product quality issues. One challenge that needs to be addressed when adopting CM technology is material traceability through the entire continuous process, which constitutes one key aspect of control strategy. Residence time distribution (RTD) plays an important role in material traceability as it characterizes the material spreading through the process. The propagation of upstream disturbances could be predictively tracked through the entire process by convolution of the disturbance and the RTD. The present study sets up the RTD-based modeling framework in a commonly used process modeling environment, gPROMS, and integrates it with existing modules and built-in tools (e.g., parameter estimation). Concentration calculations based on the convolution integral requires access to historical stream property information, which is not readily available in flowsheet modeling platforms. Thus, a novel approach is taken whereby a partial differential equation is used to propagate and store historical data as the simulation marches forward in time. Other stream properties not modeled by an RTD are determined in auxiliary modules. To illustrate the application of the framework, an integrated RTD-auxiliary model for a continuous direct compression manufacturing line was developed. An excellent agreement was found between the model predictions and experiments. The validated model was subsequently used to assess in-process control strategies for feeder and material traceability through the process. Our simulation results show that the employed modeling approach facilitates risk-based assessment of the continuous line by promoting our understanding on the process.

Similar content being viewed by others

References

Lee SL, O’Connor TF, Yang X, Cruz CN, Chatterjee S, Madurawe RD, et al. Modernizing pharmaceutical manufacturing: from batch to continuous production. J Pharm Innov. 2015;10(3):191–9.

Badman C, Trout BL. Achieving continuous manufacturing may 20–21 2014 continuous manufacturing symposium. J Pharm Sci. 2015;104(3):779–80.

Nasr MM, Krumme M, Matsuda Y, Trout BL, Badman C, Mascia S, et al. Regulatory perspectives on continuous pharmaceutical manufacturing: moving from theory to practice: September 26-27, 2016, international symposium on the continuous manufacturing of pharmaceuticals. J Pharm Sci. 2017;106(11):3199–206.

O’Connor T, Lee S. Chapter 37 - emerging technology for modernizing pharmaceutical production: continuous manufacturing. In: Qiu Y, Chen Y, Zhang GGZ, Yu L, Mantri RV, editors. Developing solid oral dosage forms. Second ed. Boston: Academic Press; 2017. p. 1031–46.

Engisch W, Muzzio F. Using residence time distributions (RTDs) to address the traceability of raw materials in continuous pharmaceutical manufacturing. J Pharm Innov. 2016;11:64–81.

FDA. Quality considerations for continuous manufacturing: guidance for industry”, Draft. 2019.

Danckwerts PV. Continuous flow systems: distribution of residence times. Chem Eng Sci. 1953;2(1):1–13.

Vanarase AU, Muzzio FJ. Effect of operating conditions and design parameters in a continuous powder mixer. Powder Technol. 2011;208(1):26–36.

Tian G, Lee SL, Yang X, Hong MS, Gu Z, Li S, et al. A dimensionless analysis of residence time distributions for continuous powder mixing. Powder Technol. 2017;315:332–8.

Billups M, Singh R. Systematic framework for implementation of material traceability into continuous pharmaceutical tablet manufacturing process. J Pharm Innov. 2020;15(1):51–65.

Bhaskar A, Singh R. Residence time distribution (RTD)-based control system for continuous pharmaceutical manufacturing process. J Pharm Innov. 2018:1–16.

Tian G, Koolivand A, Arden NS, Lee S, O'Connor TF. Quality risk assessment and mitigation of pharmaceutical continuous manufacturing using flowsheet modeling approach. Comput Chem Eng. 2019;129:106508.

Barrasso D, Bermingham S. Design space characterization and risk assessment through mechanistic modeling. Pharm Technol. 2018;42(11):46–9.

Garcia-Munoz S, Slade D, Butterbaugh A, Leavesley I, Francis Manley L, Bermingham S. A flowsheet model for the development of a continuous process for pharmaceutical tablets: an industrial perspective. AICHE J. 2017;64:511–25.

Singh R, Muzzio F, Ierapetritou M, Ramachandran R. Plant-wide control of a continuous tablet manufacturing for quality-by-design based pharmaceutical manufacturing. Computer Aided Chemical Engineering. 37: Elsevier; 2015. p. 2183–8.

Boukouvala F, Niotis V, Ramachandran R, Muzzio FJ, Ierapetritou MG. An integrated approach for dynamic flowsheet modeling and sensitivity analysis of a continuous tablet manufacturing process. Comput Chem Eng. 2012;42(0):30–47.

Yoon S, Galbraith S, Cha B, Liu H. Chapter 5 - Flowsheet modeling of a continuous direct compression process. In: Singh R, Yuan Z, editors. Computer Aided Chemical Engineering. 41: Elsevier; 2018. p. 121–39.

Wang Z, Escotet-Espinoza MS, Ierapetritou M. Process analysis and optimization of continuous pharmaceutical manufacturing using flowsheet models. Comput Chem Eng. 2017;107:77–91.

Galbraith SC, Park S, Huang Z, Liu H, Meyer RF, Metzger M, et al. Linking process variables to residence time distribution in a hybrid flowsheet model for continuous direct compression. Chem Eng Res Des. 2020;153:85–95.

Helal NA, Elnoweam O, Eassa HA, Amer AM, Eltokhy MA, Helal MA, et al. Integrated continuous manufacturing in pharmaceutical industry: current evolutionary steps toward revolutionary future. Pharm Pat Anal. 2019;8(4):139–61.

Galbraith SC, Liu H, Cha B, Park SY, Huang Z, Yoon S. Modeling and simulation of continuous powder blending applied to a continuous direct compression process. Pharm Dev Technol. 2018;23(10):1097–107.

Pereira GC, Muddu SV, Román-Ospino AD, Clancy D, Igne B, Airiau C, et al. Combined feedforward/feedback control of an integrated continuous granulation process. J Pharm Innov. 2019;14(3):259–85.

Rogers AJ, Hashemi A, Ierapetritou MG. Modeling of particulate processes for the continuous manufacture of solid-based pharmaceutical dosage forms. Processes. 2013;1(2):67–127.

Boukouvala F, Chaudhury A, Sen M, Zhou R, Mioduszewski L, Ierapetritou MG, et al. Computer-aided flowsheet simulation of a pharmaceutical tablet manufacturing process incorporating wet granulation. J Pharm Innov. 2013;8(1):11–27.

Dosta M, Litster JD, Heinrich S. Flowsheet simulation of solids processes: current status and future trends. Adv Powder Technol. 2020;31(3):947–53.

Metta N, Ghijs M, Schäfer E, Kumar A, Cappuyns P, Assche IV, et al., editors. Dynamic flowsheet model development and sensitivity analysis of a continuous pharmaceutical tablet manufacturing process using the wet granulation Route2019.

Zhang L, Mao H, Liu Q, Gani R. Chemical product design – recent advances and perspectives. Current Opinion in Chemical Engineering. 2020;27:22–34.

Aqar DY, Rahmanian N, Mujtaba IM. Optimal design and operation of semi-batch reactive distillation for methyl lactate synthesis with fixed product demand. In: Kravanja Z, Bogataj M, editors. Computer Aided Chemical Engineering. 38: Elsevier; 2016. p. 895–900.

Su Q, Reklaitis GV, Nagy ZK. Continuous feeding-blending in pharmaceutical continuous manufacturing. In: Nagy ZK, El Hagrasy A, Litster J, editors. Continuous pharmaceutical processing. Cham: Springer International Publishing; 2020. p. 193–226.

Escotet-Espinoza MS, Rogers A, Ierapetritou MG. Optimization methodologies for the production of pharmaceutical products. In: Ierapetritou MG, Ramachandran R, editors. Process simulation and data modeling in solid Oral drug development and manufacture. New York, NY: Springer New York; 2016. p. 281–309.

Katz J, Diangelakis NA, Pistikopoulos EN. Model approximation in multiparametric optimization and control – a computational study. In: Eden MR, Ierapetritou MG, Towler GP, editors. Computer Aided Chemical Engineering. 44: Elsevier; 2018. p. 655–60.

Martinetz M, Karttunen A, Sacher S, Wahl P, Ketolainen J, Khinast J, et al. RTD-based material tracking in a fully-continuous dry granulation tableting line. Int J Pharm. 2018;547(1–2):469–79.

Kruisz J, Rehrl J, Sacher S, Aigner I, Horn M, Khinast JG. RTD modeling of a continuous dry granulation process for process control and materials diversion. Int J Pharm. 2017;528(1–2):334–44.

Roos C, Westergren J, Dahlgren D, Lennernäs H, Sjögren E. Mechanistic modelling of intestinal drug absorption - the in vivo effects of nanoparticles, hydrodynamics, and colloidal structures. Eur J Pharm Biopharm. 2018;133:70–6.

Parrott N, Lave T. Applications of physiologically based absorption models in drug discovery and development. Mol Pharm. 2008;5(5):760–75.

Metwally AA, Hathout RM. Computer-assisted drug formulation design: novel approach in drug delivery. Mol Pharm. 2015;12(8):2800–10.

Koolivand A, Dimitrakopoulos P. Deformation of an elastic capsule in a microfluidic T-junction: settling shape and moduli determination. Microfluid Nanofluid. 2017;21(5):89.

Koolivand A, Dimitrakopoulos P. Motion of an elastic capsule in a trapezoidal microchannel under stokes flow conditions. Polymers (Basel). 2020;12(5):1144.

Zidan A, Alayoubi A, Asfari S, Coburn J, Ghammraoui B, Aqueel S, et al. Development of mechanistic models to identify critical formulation and process variables of pastes for 3D printing of modified release tablets. Int J Pharm. 2019;555:109–23.

Li L, Kemp I, Palmer M. A DEM-based mechanistic model for scale-up of industrial tablet coating processes. Powder Technol. 2020;364:698–707.

Weinekötter R. Gericke H. Springer Netherlands: Mixing of Solids; 2000.

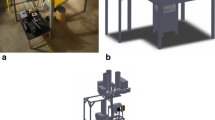

Oka S, Escotet-Espinoza M, Singh R, Scicolone J, Hausner D, Ierapetritou M, et al. Design of an integrated continuous manufacturing system. 2017. p. 405–46.

Furukawa R, Singh R, Ierapetritou M. Effect of material properties on the residence time distribution (RTD) of a tablet press feed frame. Int J Pharm. 2020;119961.

Mesbah A, Paulson JA, Lakerveld R, Braatz RD. Model predictive control of an integrated continuous pharmaceutical manufacturing pilot plant. Org Process Res Dev. 2017;21(6):844–54.

Simonaho S-P, Ketolainen J, Ervasti T, Toiviainen M, Korhonen O. Continuous manufacturing of tablets with PROMIS-line — Introduction and case studies from continuous feeding, blending and tableting. Eur J Pharm Sci. 2016;90:38–46.

Engisch WE, Muzzio FJ. Feedrate deviations caused by hopper refill of loss-in-weight feeders. Powder Technol. 2015;283:389–400.

Ervasti T, Simonaho S-P, Ketolainen J, Forsberg P, Fransson M, Wikström H, et al. Continuous manufacturing of extended release tablets via powder mixing and direct compression. Int J Pharm. 2015;495(1):290–301.

Blackshields CA, Crean AM. Continuous powder feeding for pharmaceutical solid dosage form manufacture: a short review. Pharm Dev Technol. 2018;23(6):554–60.

Van Snick B, Holman J, Cunningham C, Kumar A, Vercruysse J, De Beer T, et al. Continuous direct compression as manufacturing platform for sustained release tablets. Int J Pharm. 2017;519(1):390–407.

Kleinebudde P, Khinast J, Rantanen J. Continuous manufacturing of pharmaceuticals: Wiley; 2017.

Author information

Authors and Affiliations

Corresponding author

Additional information

Guest Editors: Alexander Russell and Maxx Capece

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

APPENDIX

APPENDIX

To show that by using the advection problem described it is possible to propagate historical state information to the current simulation values. The method of characteristics will be used. The first step to the method of characteristics is to propose that all variables, dependent and independent, are functions of a single characteristic variable s, i.e. f(t, a) = g(s). The problem is then transformed to a system of ordinary differential equations by writing the total derivative of g using the chain rule of differentiation as shown below.

By comparing Eqs. (4) to (7), it is possible to obtain the following system of ordinary differential equations for our system:

The initial conditions for this problem need to be chosen carefully. Based on the equation for g it is clear that the solution is that g remains constant with the characteristic value. That is to say that the following equation must hold:

Based on the original replacement that was performed, the original variable f can now be replaced to obtain the solution.

Comparing this result to the initial conditions that are presented in Eq. (5) give us an indication for the choice of initial conditions. Note that if the initial condition f(0, a) = 0 is used, the result is a solution, albeit a very uninteresting one physically. However, the solution that is being sought can be found by examining the boundary condition, f(t, 0) = ΔCin(t). This would indicate that it is desirable to trace characteristics in time, where t(0) = t0 and a(0) = 0. The result of this choice of initial conditions is that t(s) = t0 + s and a(s) = s. Using this solution, the following characteristic curve for time is defined:

This characteristic equation is then used to finally solve the problem fully for f by substituting back into Eq. (10) recognizing that this is equivalent to writing f(t, a) = f(t0, 0) with the choice of initial conditions that was made previously. The final result is shown below:

This result is what is needed in the convolution integral that needs to be calculated in gPROMS.

Rights and permissions

About this article

Cite this article

Tian, G., Koolivand, A., Gu, Z. et al. Development of an RTD-Based Flowsheet Modeling Framework for the Assessment of In-Process Control Strategies. AAPS PharmSciTech 22, 25 (2021). https://doi.org/10.1208/s12249-020-01913-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-020-01913-8