Abstract

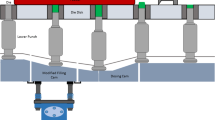

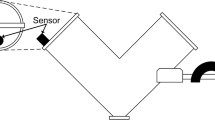

The aim of this study was to investigate the concept of lower punch vibration as a possible approach to densify the powder bed within the die of a rotary tablet press. Therefore, a laboratory vibration equipment was developed to obtain a better understanding of the performance characteristics and effects of a pneumatically generated vibration system on pharmaceutical powders. For this purpose, two widely used pharmaceutical powders, basic magnesium carbonate (Pharmagnesia MC Type F) and microcrystalline cellulose (Ceolus® KG1000), both with different physical properties, were investigated. The powders were characterized by laser diffraction, scanning electron microscopy, helium pycnometry, ring shear testing, gas adsorption, and by determination of the powder flowability. Furthermore, the extent of densification within the die during vibration was visualized by a high-speed camera system and analyzed by an image-analyzing software. It was observed that lower punch vibration was able to densify the powder bed to a sufficient extent and within an adequate time period. Consequently, the presented results revealed that lower punch vibration may be a promising technique to remove entrapped air from powder beds, thus obtaining a denser powder bed within the die, which might potentially improve the tableting process and prevent complications during tablet manufacture.

Similar content being viewed by others

References

Sastry SV, Nyshadham JR, Fix JA. Recent technological advances in oral drug delivery – a review. Pharm Sci Technol Today. 2000;3:138–45.

Hindiyeh M, Altalafha T, Al-Naerat M, Saidan H, Al-Salaymeh A, Sbeinati L, et al. Process modification of pharmaceutical tablet manufacturing operations: an eco-efficiency approach. Processes. 2018;6:15–23.

Bolhuis GK, Lerk CF, Moes JR. Comparative evaluation of excipients for direct compression. Pharm Weekbl Sci. 1979;1:1473–82.

Jivraj M, Martini LG, Thomson CM. An overview of the different excipients useful for the direct compression of tablets. Pharm Sci Technol Today. 2000;3:58–63.

Zhang Y, Law Y, Chakrabarti S. Physical properties and compact analysis of commonly used direct compression binders. AAPS PharmSciTech 2003;4:Article 62.

Saniocki I, Sakmann A, Leopold CS. Direct compression of ibuprofen-containing powder blends influence of the ibuprofen grade on the flow and compaction properties of an ibuprofen tablet formulation. Pharm Ind. 2012;74:1842–52.

Parikh DM. Handbook of pharmaceutical granulation technology. 3rd ed. New York: Informa Healthcare; 2010.

Gohel MC. A review of co-processed directly powder excipients. J Pharmacy Pharm Sci. 2005;8:76–93.

Bozic DZ, Dreu R, Vrecer F. Influence of dry granulation on compactibility and capping tendency of macrolide antibiotic formulation. Int J Pharm. 2008;357:44–54.

Šantl M, Ilić I, Vrečer F, Baumgartner S. A compressibility and compactibility study of real tableting mixtures: the impact of wet and dry granulation versus a direct tableting mixture. Int J Pharm. 2011;414:131–9.

Ripple CD, James RV, Rubin J. Radial particle-size segregation during packing of particulates into cylindrical containers. Powder Technol. 1973;8:165–75.

Bateman SD, Rubinstein MH, Thacker HS. Pre- and main compression in tableting. Pharm Technol Int. 1990;2:30–6.

Ruegger CE, Celik M. The influence of varying precompaction and main compaction profile parameters on the mechanical strength of compacts. Pharm Dev Technol. 2000;5:495–505.

Vezin WR, Pang HM, Khan KA, Malkowska S. The effect of precompression in a rotary machine on tablet strength. Drug Dev Ind Pharm. 2008;9:1465–74.

Akseli I, Ladyzhynsky N, Katz J, He X. Development of predictive tools to assess capping tendency of tablet formulations. Powder Technol. 2013;236:139–48.

Adam A, Schrimpl L, Schmidt PC. Factors influencing capping and cracking of mefenamic acid tablets. Drug Dev Ind Pharm. 2000;26:489–97.

Kakimi K, Niwa T, Danjo K. Influence of compression pressure and velocity on tablet sticking. Chem Pharm Bull. 2010;58:1565–8.

Emeruwa E, Jarrige J, Mexmain J, Billy M, Bouzouita K. Powder compaction with ultrasonic assistance. J Mater Sci. 1990;25:1459–62.

Pan R, Mi B, Wypych P. Pneumatic conveying characteristics of fine and granular bulk solids. KONA. 1994;12:77–85.

Bityukov VK, Podoskin AS. Dust removal from tableted preparations. Pharm Chem J. 1976;10:106–8.

Levina M, Rubinstein MH, Rajabi-Siahboomi AR. Principles and application of ultrasound in pharmaceutical powder compression. Pharm Res. 2000;17:257–65.

Cha HR. Densification of the nanopowder by using ultrasonic vibration compaction. Rev Adv Mater Sci. 2011;28:90–3.

Levina M, Rubinstein MH. The effect of ultrasonic vibration on the compaction characteristics of paracetamol. J Pharm Sci. 2000;89:705–23.

Levina M, Rubinstein MH. The effect of ultrasonic vibration on the compaction characteristics of ibuprofen. Drug Dev Ind Pharm. 2002;28:495–514.

Rodriguez L, Cini M, Cavallari C, Passerini N, Saettone M, Fini A, et al. Evaluation of theophylline tablets compacted by means of a novel ultrasound-assisted apparatus. Int J Pharm. 1998;170:201–8.

Behrens B-A, Gastan E, Vahed N. Application of tool vibration in die pressing of Ti-powder. Prod Eng Res Dev. 2010;4:545–51.

May RK, Su K, Han L, Zhong S, Elliott JA, Gladden LF, et al. Hardness and density distributions of pharmaceutical tablets measured by terahertz pulsed imaging. J Pharm Sci. 2013;102:2179–86.

Akseli I, Iyer S, Lee HP, Cuitino AM. A quantitative correlation of the effect of density distributions in roller-compacted ribbons on the mechanical properties of tablets using ultrasonics and X-ray tomography. AAPS PharmSciTech. 2011;12:834–53.

Sancin P, Caputo O, Cavallari C, Passerini N, Rodriguez L, Cini M, et al. Effects of ultrasound-assisted compaction on Ketoprofen/Eudragit® S100 mixtures. Eur J Pharm Sci. 1999;7:207–13.

Mooser Schwingungstechnik. Pneumatic Vibrators. http://www.mooser.net/en/industry-products/pneumatic-vibrators/directional-vibration/piston-vibrators-mkk.html. Accessed april 2018.

Frankel EJ, Wang KK. Energy transfer and bond strength in ultrasonic welding of thermoplastics. Polym Eng Sci. 1980;20:396–401.

Schmidt I, Naeve J, Heinrich T. Rotary tablet press and method for pressing tablets in a rotary tablet press; 2011; US 9.327.469B2.

Grove C, Jerram DA. jPOR: an ImageJ macro to quantify total optical porosity from blue-stained thin sections. Comput Geosci. 2011;37:1850–9.

Sezgin M, Sankur B. Survey over image thresholding techniques and quantitative performance evaluation. J Electron Imaging. 2004;13:146–65.

European Pharmacopeia 9.0, 2.9.34. Bulk density and tapped density of powders. Strasbourg: European Pharmacopeia Commission, European Directorate for the Quality of medicines; 2018. p. 359–61.

European Pharmacopeia 9.0, 2.9.36. Powder flow. Strasbourg: European Pharmacopeia Commission, European Directorate for the Quality of Medicines; 2018. p. 362–5.

Mellmann J, Hoffmann T, Fürll C. Flow properties of crushed grains as a function of the particle shape. Powder Technol. 2013;249:269–73.

Acknowledgements

The authors thank Lehmann & Voss for the supply of the powder materials and Yuan Yang for supporting the development of the vibration rig.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kalies, A., Özcoban, H. & Leopold, C.S. Performance Characteristics of a Novel Vibration Technique for the Densification of a Powder Bed within a Die of a Rotary Tablet Press — a Proof of Concept. AAPS PharmSciTech 20, 148 (2019). https://doi.org/10.1208/s12249-019-1351-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-019-1351-x