Abstract

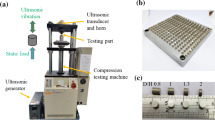

Titanium and its alloys have a vast range of applications in the chemical, aeronautical and aerospace industries as well as in medical engineering, based on their high specific strength and high corrosion resistance. Regarding the fact that titanium is an expensive material, powder metallurgy can be a notably economized production solution which offers the maximum material utilization compared to shape cutting processes. Among all forming processes of metallic powder, die pressing is one of the most widespread processing methods. A common effect of this method is residual porosity in the produced parts, which has negative impacts on their mechanical stability. This study shows how the porosity can be reduced by means of induced vibration in the pressing tool. Consequently, the mechanical properties of the product can be improved. Further studies are aimed at investigating the methods of increasing the homogeneity of density allocation.

Similar content being viewed by others

References

Peters M, Leyens C (2002) Titan und Titanlegierungen, 3. Ausgabe, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Zwicker U (1974) Titan und Titanlegierungen, Reine und angewandte Metallkunde in Einzeldarstellungen, vol 21. Springer, Berlin

Schultheis V (2007) Oszillierendes Umformen mit direkt angetriebenen Umformmaschinen, Dissertation TU Darmstadt, Shaker Verlag

Grupp P, Richter W (2006) Frequenzmoduliertes Axialformen–flexible Fertigung von Innen- und Außenverzahnungen, 9. Umformtechnisches Kolloquium Darmstadt, Verlag Meisenbach GmbH, Bamberg, pp 49–57

Kurz G (2000) Geregelter Tiefziehprozess mit pulsierenden Niederhalter auf einfachwirkenden Pressen, Abschlussbericht AiF 11903, IFUM, Universität Hannover

Lehfeldt E (1968) Metallische Reibungsvorgänge im 20 kHz-Bereich, Dissertation RWTH Aachen

Shatalova IG, Gorbunov NS, Likhtman VI (1967) Physicochemical principles of vibratory compacting, perspectives in powder metallurgy. Plenum Press, New York

DIMEC (2006) Gamma Densomat—Bedienungshandbuch, Köln

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Behrens, BA., Gastan, E. & Vahed, N. Application of tool vibration in die pressing of Ti-powder. Prod. Eng. Res. Devel. 4, 545–551 (2010). https://doi.org/10.1007/s11740-010-0239-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0239-0